For as versatile and malleable as plastic is, the material is far from ideal for those who want to create a greener future. Enter bioplastics – plastic-like materials that biodegrade within months rather than the centuries required for traditional plastics. With bioplastics, manufacturers transform their packaging so that it’s eco-friendly and, as is the case with REGEN™, compostable even in natural environments.

Reducing pollution, cutting down on resource usage, and adapting to changing consumer desires are all benefits that bioplastics offer. They deliver on the dream of having a material that provides the benefits of plastics without its dangerous downsides. Made from natural sources, like plant matter, bioplastics offer a sustainable alternative to conventional ones.

They’ve got smaller carbon footprints. They don’t pollute the planet anywhere near as much. They’re even capable of decomposing in months in the right conditions. This all makes them a dream fit for the packaging industry, as this guide explores.

What Are Bioplastics?

Bioplastics are plastic-like substances made using biological substances such as plants or bacteria. They’re made using renewable materials, unlike petroleum-based plastics, but often share similar characteristics. They can be just as tough and flexible.

Starch-based bioplastics, for example, can have a tensile strength of between 0.22 and 18.49 MPa, which compares well to the 29.8 MPa tensile strength of acrylonitrile butadiene styrene (ABS) plastic. More research may increase this strength, allowing bioplastics to fulfill similar roles in industry to traditional plastics without harming the environment.

There are multiple types of bioplastics, with four of the most well-known being:

- PLA: PLA stands for polylactic acid, and this popular bioplastic comes from plant materials like sugarcane and corn starch.

- PHA: Polyhydroxyalkanoates are another very popular form of bioplastic, created with the aid of microorganisms, like bacteria, and feedstocks, like plant oils or agricultural waste.

- PHB: Another form of PHA, PHB (polyhydroxybutyrate) is also extracted from bacteria that have received certain natural feedstocks.

- PBS: Polybutylene succinate bioplastics are made from renewable resources such as corn and sugar plants.

Compared to conventional plastics, bioplastics have much smaller impacts on the environment. Since they’re made using natural polymers and renewable sources rather than fossil fuels, which require damaging extraction and processing, they don’t have such a big carbon footprint.

Nor do they drain as much of the world’s resources as demonstrated in detailed lifecycle assessments. For instance, PLA saves 66% of the energy required to create more conventional plastics – a substantial and eco-friendly decrease.

Many bioplastics are biodegradable (they decompose under specific conditions). Some are suitable for composting, too, though they may require industrial composting facilities to break down in the most efficient ways. Through this, they decompose into safe, natural elements, like water and carbon dioxide, feeding the soil and helping more plants grow to make more bioplastics in the future.

All this helps bioplastics contribute to waste reduction, and the brands that use them align with eco-friendly practices and standards in their respective industries.

To learn more about the benefits these materials bring to various industries, read our in-depth article on the advantages of bioplastics, which highlights how they help reduce pollution and lower carbon footprints.

If you want to explore further, REGEN™ offers an alternative to traditional plastics. ASTM D6400-certified as compostable, our bioplastic biodegrades within six months at an appropriate industrial composting facility as is as practical as plastic – Learn More Today.

The Rise of Bioplastics

While bioplastics may seem like a very recent innovation, as they’re only now emerging into the spotlight in many industries, they’ve been around quite a while:

- The first bioplastic, which was cellulose-based, was invented in the mid-1800s.

- Progress was slow, but European researchers experimented with making more bioplastics in the decades after.

- By 1930, titans of industry started to take notice. Henry Ford, for example, used bioplastics (soy-based) in some of his car designs.

- By the late 20th century, research sped up. Scientists found that it was possible to make plastics that could biodegrade, and the first big bioplastics brands emerged.

- With the new millennium, bioplastics like PHA and PLA entered mass production and spread to numerous industries.

- Now, at a time with more focus on sustainability than ever, the true “age of bioplastics” has arguably begun.

There’s no doubt bioplastics have come far. But they’ve still got space to grow, to develop, to evolve. And that evolution will speed up in the years ahead thanks to three key factors:

- Better tech makes bioplastics easier to work with, develop, and even combine.

- Growing levels of sustainability awareness make consumers more eager to embrace bioplastic.

- Governments, too, incentivize bioplastic development and usage.

How Are Bioplastics Made?

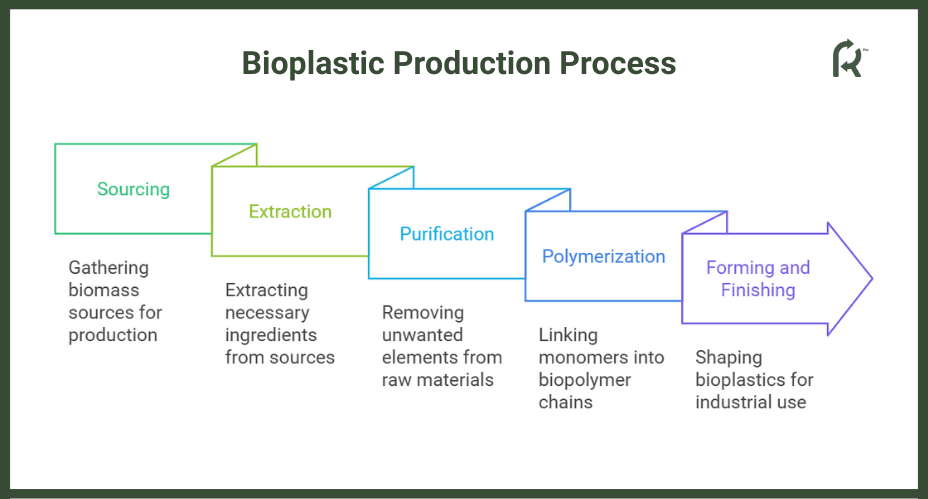

The exact steps for making bioplastics vary from one material to the next. PHAs, for instance, require feeding bacteria with specific feedstocks before placing the microorganisms in controlled conditions to encourage them to produce biopolymers. However, the steps below show a simple, generalized look at a bioplastic production process:

- Sourcing: The biomass sources needed for plastic production are sourced. This might mean growing and harvesting plants or collecting waste materials, for example.

- Extraction: The necessary ingredients or raw materials are then extracted, like oils extracted from plants or PHAs extracted from bacteria.

- Purification: The raw materials have to pass through purification processes to eliminate any unwanted or harmful elements.

- Polymerization: The biopolymers or monomers are then put through polymerization or joining process, linking polymers together into chains and structures – building blocks of bioplastics.

- Forming and Finishing: The biopolymers can then be formed and finished into the appropriate shapes, sizes, and grades for industrial use.

Bioplastics in Packaging

The many benefits of bioplastics make them the perfect fit for the packaging industry – an industry that has long been the bane of the environment, contributing to widespread pollution and other issues.

Manufacturers can use these materials to create sustainable packaging like bags, boxes, liners, and wraps. Add bioplastics’ collective non-toxic, biodegradable, and flexible qualities and you get a material that can cover and protect several types of items.

For more information on how these materials break down and return to the environment, check out our guide on biodegradable materials, explaining how different types of packaging materials can decompose safely.

Food Packaging

Bioplastics are ideal for packaging food and drink items, thanks to their non-toxic nature. They don’t pass any harmful elements onto the food items they cover up, nor do they impact flavor or smell. Many even have strong barrier properties to block out moisture and oxygen, keeping food fresher for longer. They’re ideal for water bottles, food wrappers, trays, and more.

Cosmetics

Cosmetics plastic packaging is a colossal contributor to pollution with the industry generating 120 billion packaging units annually, most made using traditional plastics.

All those bottles, tubs, and containers can end up in natural environments, taking centuries to finally break down. Bioplastics are much better, helping to reduce environmental impact, minimize carbon footprint, and even bolster beauty brands’ green credentials in the eyes of their consumers.

Try REGEN™’s Luxe Pack NY 2024 cosmetics packaging to discover what a 100% compostable and fossil fuel-free cosmetics package delivers to your customers.

Pharmaceuticals

Green and sustainable bioplastics are also proving popular for pharmaceutical packaging – like pill bottles and blister packs. Their flexibility allows for forming into the specific shapes that pharmaceutical packaging demands and many of them exhibit strong levels of chemical resistance. This, combined with the aforementioned barrier properties, helps them keep pills and medicines safe without any unwanted risks.

What Are Bioplastics Used For?

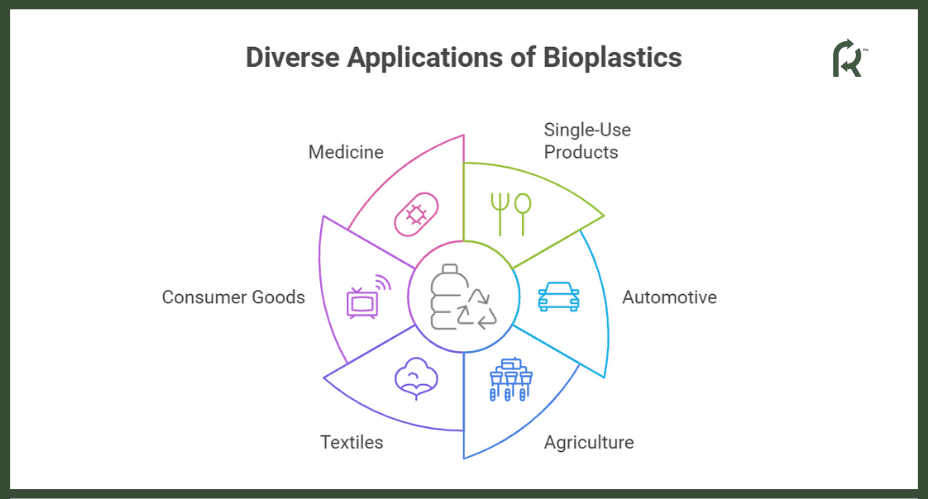

Packaging is one of the vast and ever-expanding array of bioplastic applications. They’re used in numerous other forms and industries, including:

- Single-Use Products: Bioplastics that are compatible with existing recycling systems are ideal for single-use products. That applies to the likes of disposable cutlery and straws, which users can recycle safely in the knowledge that the materials align with existing systems or, as with REGEN™, are compostable.

- Automotive: We mentioned how Henry Ford introduced early bioplastics into his car designs. The modern automotive industry is embracing bioplastics, too, using them for dashboards, door panels, and even under-the-hood parts.

- Agriculture: In agriculture, bioplastics have myriad applications. They’re used for pot linings which break down and feed the soil in the process, seed coatings to help seeds sprout more efficiently, and mulch-like soil covers to guard against erosion.

- Textiles: A lot of bioplastics can blend with other materials to produce advanced biopolymer blends with different textures and qualities. This makes them ideal for producing fabrics, clothing, and other textiles.

- Consumer Goods: We’re also starting to see bioplastics featured in more everyday consumer goods, such as toys for children and even parts of appliances and electronic devices, like keyboard keys and computer cases.

- Medicine: Bioplastics are used in medical applications, such as dissolvable sutures and single-use drug delivery systems. They offer high levels of biocompatibility, making them safe for the human body.

If you’re curious about how biodegradable plastics are reshaping industries, read our detailed overview of biodegradable plastics to learn more about their impact and versatility.

REGEN™ Bioplastics: A Case Study

Bioplastics are becoming much more popular as they help in achieving sustainability goals and offer tunable mechanical properties, opening up lots of possible applications.

However, they’re not perfect. They face challenges in large-scale production, for example, and don’t always have the strength, resistance, or crucial sustainability features certain industries demand.

REGEN™ Bioplastics aims to change that. Created by BOSK Bioproducts, REGEN™ is an innovative new form of PHA-based bioplastic made from renewable resources. Bio-based, compostable, and with several more key features, REGEN™ pushes the boundaries of what bioplastics are capable of, taking the very concept of biological plastic to ever greater heights.

Properties of REGEN™ Bioplastics

REGEN™ bioplastics boast an array of key qualities that set them apart from the rest. They’re biodegradable, so they can break down through microbial action rather than sitting in landfills decade after decade. They’re also strong, flexible, and non-toxic, which opens lots of doors in terms of applications involving food, drink, or even medical products.

High Performance and Durability

One of the big issues with many bioplastics is that they aren’t able to match conventional plastics for strength and other mechanical aspects. REGEN™ is different:

- Exceptional levels of tensile strength

- Long-lasting durability for intense applications

- Mechanical properties to rival resin-based plastics

Certified Biobased and Compostable

REGEN™ is bio-based, which means BOSK Bioproducts uses natural resources in production. In the specific case of REGEN™, made with PHA (which comes from bacteria) that is mixed with other ingredients, like wood fibers and biopolymers.

These additional ingredients add key characteristics to the final product while preserving its natural, renewable state.

What’s more, REGEN™ is also certified compostable in accordance with ASTM D6400 standards. In the right setting – like an industrial compost facility – it’ll break down into water, CO2, and other harmless elements.

It doesn’t leave any toxic residues behind or microplastics seeping into the soil. That makes REGEN™ one of the most genuinely sustainable bioplastics of the moment – Learn more about the REGEN™ revolution today.

Innovations and Future Prospects

It’s an exciting time for bioplastics, and the future looks particularly bright. In Canada, for example, research teams are exploring ways to take organic materials that would usually go to waste and reuse them for bioplastic production instead.

Simultaneously, studies are looking at ways to better recycle bioplastics, using fewer resources and with smaller energy demands.

Thanks to this, we can expect to see a lot of exciting developments related to bioplastics in the years to come, like:

- More widespread adoption of bioplastics in varied industries

- Better disposal and recycling methods

- Development of stronger bioplastics that can cope with higher temperatures

- A healthier planet as a result of reduced reliance on conventional plastics

Key Takeaways

- Bioplastics require natural and renewable resources, like plants and bacteria, for manufacture.

- They’ve evolved over the last century to become relevant and useful to modern industry.

- They’re ideal for packaging bags, boxes, and more but have dozens more uses.

- Their biodegradable and renewable nature makes them a driving force for sustainability.

- In the years to come, bioplastics should get even better, as shown by projects like REGEN™.

Frequently Asked Questions

What Products Can Be Made from Biodegradable Plastics?

There are lots of different products made of biodegradable plastics nowadays. Disposable cutlery, packaging solutions, car parts, medical devices, the list of applications is quite diverse, and growing even more varied by the day. As these materials get stronger, thanks to ongoing research efforts, we’ll see even more products made partly or wholly of bioplastics.

How Long Does Biodegradable Plastic Last?

That depends on both the type of plastic and the conditions in which it finds itself. Different plastics break down faster than others, and conditions like warmth, moisture, and oxygen levels can all hasten their biodegradation. On average, in the right conditions, bioplastics break down within a few months or less, but it may take much longer in some cases.

What Is the Best Source of Bioplastics?

There’s no single “best” source of bioplastics. They’re all different. Plant materials – like corn and sugar – reign supreme in terms of renewability. Microorganisms are an excellent source for generating versatile, strong bioplastics. From a sustainability perspective, waste materials – food and farm waste – are particularly good to work with.