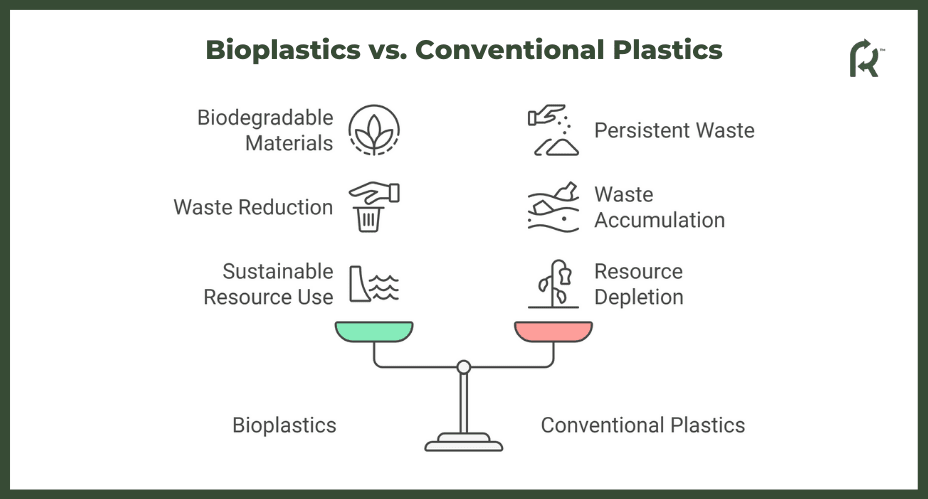

Bioplastics offer companies a chance to overcome some of the downsides of traditional plastics, such as their resource-intensive production processes and lack of biodegradability.

Made using naturally occurring materials, bioplastics lower a company’s carbon emissions, satisfy growing consumer desires for sustainable products, and offer recyclable and, as with REGEN™, compostable alternatives to products that take centuries to biodegrade.

There’s a pressing need to uncover alternative materials that create less pollution, support waste reduction, and decrease dependence on fossil fuels to replace traditional plastics. That’s where bioplastics come in.

The advantages we’ve already mentioned make bioplastics a suitable alternative for food packaging, single-use medical items, and much more. Let’s explore those advantages across different industries to see why so many companies are making the switch to bioplastics.

What Are Bioplastics?

In simple terms, bioplastics are plastic-like materials made using renewable, natural resources, like plant sugars and oils using bacteria, as opposed to the fossil fuels that form conventional plastics. Bioplastics offer renewable alternatives to regular plastics and promote sustainability in the industries in which they’re used.

Many forms of bioplastics also boast impressive properties, like respectable levels of strength, flexibility, good barrier properties, and chemical resistance.

A lot of them (but not all) are biodegradable, too, meaning that they can decompose naturally into safe, organic matter. Some are even compostable, breaking down in a matter of months and replenishing the soil with nutrients.

Examples of bioplastics include:

- PLA (polylactic acid)

- PHA (polyhydroxyalkanoates)

- Polybutylene succinate (PBS)

- Polyhydroxybutyrate (PHB)

To explore more about the various types of bioplastics and their benefits, visit our comprehensive guide on bioplastics to understand how these materials are transforming industries.

REGEN™ is an example of a PHA, though one that’s blended with other ingredients, including wood fibers and natural additives, to create a bioplastic that is tough and biodegrades in under 180 days. Discover REGEN™ for a TUV Austria-approved alternative to traditional plastics.

Advantages of Bioplastics

There are many advantages of bioplastics, setting them above other materials and making them a popular choice in numerous industries.

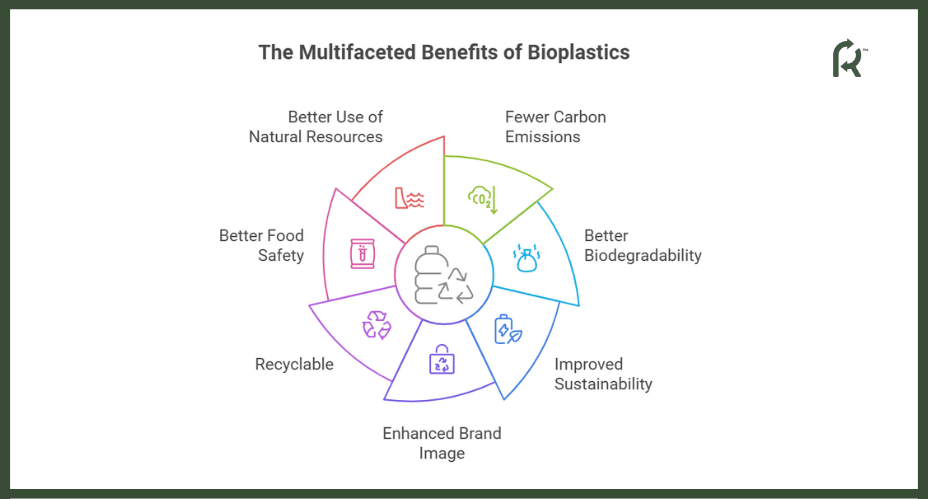

Fewer Carbon Emissions

One of the biggest advantages of bioplastics is that they’re made from natural, renewable resources, not fossil fuels. Thanks to that, their production emits far fewer greenhouse gases into the atmosphere.

Switching to bioplastics, therefore, allows businesses to minimize carbon footprint size and reduce environmental impact, safeguarding the natural world for future generations.

- Bioplastics can reduce carbon emissions by at least 30%.

- Compared to conventional plastics, they have a 42% smaller carbon footprint.

- Estimates suggest that bioplastics could replace up to 90% of fossil-fuel plastics.

Better Biodegradability

A lot of bioplastics are biodegradable. In the right conditions, they’ll decompose fast(sometimes in a matter of a few months), with microorganisms, like bacteria, breaking them down.

This is a stark contrast to conventional plastics, which can remain intact in landfills, oceans, and other locations for centuries, proving much harder for bacteria to break through. REGEN™’s six-month breakdown process is a perfect example of the biodegradability inherent to the best bioplastics.

The following three factors can impact the rate at which bioplastics degrade:

- Temperature: At higher temperatures, the microbes become more active, hastening the biodegradation.

- Moisture and O2: The presence of moisture and oxygen in the environment can enhance biodegradability, as the microbes work faster in these conditions.

- Composition: Certain types of bioplastics with simpler structures and weaker links between their molecules will degrade faster.

To better understand the environmental benefits and functionality of biodegradable plastics, check out our in-depth analysis of biodegradable plastics, which highlights how they help reduce long-term waste.

Improved Sustainability

Renewable resources, like plant oils, and sugars, for the building blocks of bioplastics. For PHAs, manufacturers use algae and bacteria to break these resources down so they become usable.

Thanks to this, using bioplastics can help in achieving green goals and advance eco-friendly practices in many industries. They help to enable compliance with environmental regulations for brands in the manufacturing, retail, automotive industry, and beyond industries.

Some of the specific sustainability-related advantages of bioplastics include:

- Less reliance on fossil fuels

- Less waste and pollution in the natural world

- More efficient use of natural resources

- Fewer greenhouse gases emitted

Discover how bioplastics serve as a sustainable alternative to plastic and how they’re helping industries move towards eco-friendly practices.

Enhanced Brand Image

Stats show that more and more consumers favor sustainable products and want to support eco-conscious brands. The five years between 2019 and 2024 showcase a 71% increase in online searches for sustainable goods, with 66% of people saying they consider sustainability when making a purchase.

They’ll even pay more for sustainable products to support businesses that commit to preserving the environment. As such, using bioplastics and other sustainable solutions can provide a big boost to any brand’s public image.

- Patagonia was an early adopter of sustainable practices back in the 1980s and has proven popular with outdoorsy people and lovers of the natural world in the decades since.

- Swedish furniture giant IKEA has proven its commitment to eco-initiatives, helping it become a go-to supplier of home products for eco-conscious consumers the world over.

- Ben & Jerry’s: In the world of food and drink, ice cream brand Ben & Jerry’s has made sustainability a big part of its philosophy, marketing, and identity.

Recyclable

Many bioplastics are also recyclable – companies can break them down into their individual components and then reshape the plastics for new uses. They can be broken down in numerous ways, including mechanical methods (like shredding or melting plastics down) or chemical methods (using chemicals to break them down before reforming them).

This presents both benefits and challenges. Benefits include:

- Using bioplastics can help brands support recycling initiatives in their industries.

- Many bioplastics are recyclable in numerous ways, which helps to improve waste management practices.

- Some bioplastics allow for constant reuse, which is great for the environment.

Meanwhile, three key challenges include:

- The costs of recycling bioplastics can be higher than sourcing fresh ones.

- It takes time, resources, and often industrial conditions to recycle bioplastics.

- They aren’t all suitable for recycling.

Better Food Safety

The food and drink industry is one of many that benefit from the rise of bioplastics. These materials are often non-toxic, so they’re safe to use on foods and drinks fit for human consumption, and they don’t tend to pass on any smell or flavor to the products they package. They also have good barrier properties to extend the shelf life of food items and stop them from going bad.

- Authorities around the world run certification tests on materials (like bioplastics) to ensure they’re safe for use with food.

- The Food and Drug Administration (FDA), for example, approves the likes of PLA as “food-safe.”

- There are also strict standards in place in the EU, while Canada’s Health Canada Food Directorate regularly evaluates food packaging safety.

Better Use of Natural Resources

One of the recurring advantages of bioplastics is how much they help the environment. Whether it’s through their sustainability or their biodegradability, they’re better for the planet than conventional alternatives. They also help us make better use of the natural resources provided to us in the form of plants and even microorganisms.

Many leading bioplastics use these kinds of pure natural resources. Some can even be made from the likes of agricultural waste. Materials that might once have been burned up, disposed of, or dumped into landfills are now utilized and recrafted into versatile, functional materials.

Here are some hypothetical examples of this in action:

- Transitioning to bioplastic packaging could help manufacturers produce far less waste that ends up in landfills and the natural world.

- Using bioplastic-based parts for car interiors may help automotive brands harness natural resources – like plant oils and farm waste – rather than relying on fossil fuels.

- Bioplastic medical products – like dissolvable sutures and tissue scaffolds – may help to reduce healthcare’s reliance on and wastage of certain unsustainable materials.

- Bioplastics facilitate the transition to sustainable materials for brands in the agricultural sector, too, like using PHA mulch to protect soil.

Are Bioplastics and Biodegradable Plastics the Same?

No, it’s important to understand the distinction between bioplastics and biodegradable plastics and not to confuse the two, even though there is some overlap. A lot of bioplastics also fall into the biodegradable category, for example. But not all of them – all biodegradable plastics are bioplastics, but not all bioplastics are biodegradable.

Biodegradable plastics are those that can break down naturally in a specific set of conditions, like in an industrial composting facility or landfills, with the aid of microbial activity.

REGEN™ offers an example, with objects made using this ASTM D6400-certified bioplastic degrading in six months at an industrial composting facility. They decompose into natural, organic substances. There are some bioplastics made from biomass sources that are incapable of breaking down this way, meaning they aren’t biodegradable.

Are Bioplastics Better for the Environment?

Compared to traditional plastics, bioplastics are better for the natural world. They’re not perfect – it still takes resources and energy to make and dispose of them – but they’re less impactful on the planet than oil-based plastics. For example, their carbon footprint is smaller than conventional plastics, as they generate less greenhouse gas emissions in production.

Many bioplastics also contribute to a circular economy, as they break down into natural elements for reuse, composting, or returning to the soil, the latter process then feeds new plants, which manufacturers can use to create more bioplastics.

Since they’re made from renewable resources, bioplastics help to reduce mankind’s reliance on finite and harmful fossil fuels. REGEN™ commits to this process, addressing both immediate sustainability concerns and supporting long-term environmental goals due to the product’s compostability.

There are some limitations to bioplastics’ eco-friendly nature. They’re not as available as conventional plastics and generally cost more to make. Some of their production processes are quite resource-intensive, too – you need microorganisms, feedstocks, and controlled conditions to produce PHA material, for example – and they’re not all biodegradable.

Challenges and Future Prospects

Bioplastics provide compostable solutions in industries that have been crying out for them for years. They foster innovation in materials science, encourage responsible consumption, and prove that there are better, greener alternatives to the polluting, harmful plastics and other materials that have caused so many problems for nature and the wider world.

But they’re not perfect. There are challenges regarding the production and usage of these materials. For example, one of the advantages of bioplastics like PHAs is that they offer similar levels of tensile strength and elasticity to conventional plastics. But they often can’t match plastics in other areas, like long-term fortitude and heat resistance, so they’re not quite as widely useful, at the moment.

Even though bioplastics are much more sustainable in many ways than classic ones, it still takes time, money, resources, water, and so on to make them. Some of their production processes (as well as their disposal processes) are resource-intensive, so they still have quite an impact on Mother Nature.

There’s also a current lack of infrastructure in place around the world to make, manage, dispose of, and recycle bioplastics at the levels needed to trigger a true and permanent shift away from traditional plastics.

There aren’t enough facilities making these plastics or composting locations to break them down when they’re finished, though acceptance of bioplastics combined with investment into the sector will enable the scaling required to reverse this issue.

The future looks bright for bioplastics. Research is ongoing at this very moment to uncover new bioplastics, along with more efficient and effective ways to make and use them. A lot of governments are also incentivizing bioplastic use and funding innovation, which should pave the way towards a better tomorrow for bioplastics in which they’re more useful, sustainable, and stronger than ever before.

REGEN™ is a product of such research. BOSK makes this product using a special formula that combines PHA with wood fibers, biopolymers, and natural additives to create a plastic that is both strong and biodegradable.

REGEN™ filaments offer superior adhesion between layers and are ideal for single or limited-use plastic products. Canadian-made and manufactured, REGEN™ leads the charge to a more sustainable future – Learn more about our compostable bioplastic today.

Key Takeaways

- Bioplastics are plastics made from natural and renewable resources.

- They come in various forms and have a wide range of characteristics.

- Key advantages of bioplastics include their strength, flexibility, and widespread applications.

- These advantages make them useful in food and medicine packaging, and beyond.

- There are also challenges associated with the cost and production of bioplastics still to be overcome.

Frequently Asked Questions

What Makes Bioplastics Appealing to the Food and Beverage Sector?

Most bioplastics are non-toxic and carry certification noting that they’re usable for food and beverage packaging. That certification shows there’s no risk of any harmful additives or elements passing from the material into food or drinks, making bioplastics perfect for food packaging and single-use cutlery. They’re also biodegradable and sometimes even compostable, making them very simple to dispose of, with minimal waste and pollution.

Are There Applications of Bioplastics in the Automotive Industry?

Manufacturers can use the strongest bioplastics, like long-chain PHA materials with high melting temperatures, for certain automotive parts, especially inside cars and other vehicles. Examples include dashboards, interior door panels, and seat covers, all of which can be bioplastic-based. Such uses require the bioplastic to exhibit similar tensile strength and heat resistance as traditional plastics, as is the case with REGEN™.

How Do Bioplastics Compare to Traditional Plastics in Terms of Performance?

It depends on which bioplastics are being discussed. In some areas, bioplastics may struggle to match conventional ones, like tensile strength and heat resistance. However, recent improvements in bioplastic manufacture mean that many leading bioplastics, like PHA and PLA, are able to exhibit similar levels of strength, flexibility, resistance, barrier, and thermo-mechanical properties to traditional plastics.