Packaging is a problem. It’s responsible for huge amounts of environmental damage and devastation, with plastic packaging materials polluting land and oceans, poisoning ecosystems, killing wildlife, and contributing massively to climate change, too. In short, change is drastically needed in this industry, and experts are working feverishly to develop new, sustainable packaging solutions.

One of those solutions is plastic from seaweed, which is exactly what it sounds like – plastic-like packaging made from seaweed, a completely natural, fast-growing, and renewable resource. There are lots of advantages to seaweed-based packaging, like the fact it doesn’t take up land (as it grows underwater), nor does it require fancy fertilizers to grow.

Lots of seaweed packaging is biodegradable and compostable, too, which aligns with zero-waste goals and minimizes plastic pollution. What’s more, plastic from seaweed is surprisingly strong, with impressive mechanical properties. Thanks to this, it truly is an alternative to petroleum-based plastics and could even supplant those plastics someday. Let’s find out more about it.

- Understanding Conventional Plastics

- Can Seaweed Help Solve the World’s Plastic Crisis?

- How to Turn Seaweed into Plastic

- Applications of Seaweed as a Plastic Substitute

- Advantages of Seaweed-Based Plastic

- Limitations of Seaweed Packaging

- What Are Seaweed Plastic Alternatives?

- The Future of Seaweed Plastic

- Key Takeaways

- Frequently Asked Questions

Understanding Conventional Plastics

To understand the impact seaweed packaging could have on the industry, we first have to understand the conventional plastics that dominate the industry, and why they’re so problematic.

Unfortunately, many plastics—such as polystyrene and HDPE—are made using fossil fuels, which have a highly damaging impact on the environment.

For example, high-density polyethylene (HDPE) is one such plastic. To make it, petroleum is sourced as a raw material and then heated to very high temperatures, creating ethylene gas.

This gas then undergoes polymerization to form the building blocks of HDPE before additional processes, like molding, catalyzing, and extraction, are used to form the plastic. It’s then processed into various shapes.

This is just one example of many. Lots of conventional plastics come from petroleum and other fossil fuels, involving many energy-intensive stages of production, with high amounts of carbon emissions and other negative ecological effects, which we’ll get to later.

As we explore the pressing need to shift away from harmful conventional plastics, it’s important to consider all available options. Delve deeper into the variety of sustainable alternatives to plastic that offer less environmental impact and support the transition to greener industries.

What Are Traditional Plastics?

When we talk about conventional plastics, this refers to synthetic materials made from non-renewable resources – most often fossil fuels like petroleum or coal. Examples of these plastics include HDPE, LDPE, polyethylene terephthalate (PET), polyvinyl chloride (PVC), polystyrene, and polypropylene.

Each one is made in a slightly different way and has its own unique properties and chemical structure. But they all have key factors in common, like the fact that they’re synthetic and largely derived from fossil fuels. They also share certain mechanical properties and characteristics, like the fact that they typically take decades, if not centuries, to decompose.

Environmental Consequences of Conventional Plastic Use

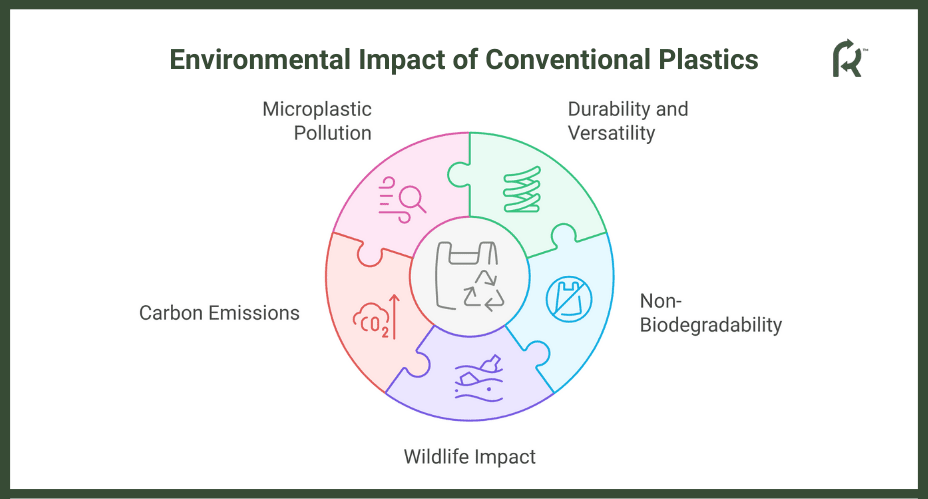

Conventional plastics have plenty of plus points. They’re strong, durable, and hard-wearing. They’re immensely flexible, too, and can be formed into all sorts of shapes and forms, from the thinnest films to thick and sturdy boxes and containers. This is why they’ve become such important materials in today’s industrialized world, used in packaging, agriculture, manufacturing, and countless more industries.

Unfortunately, they have severe downsides, especially from an environmental perspective. Given that they don’t biodegrade (break down naturally), they often end up in landfills, oceans, or other parts of the natural world, where they stay for years and years. They gradually get smaller, but that’s problematic, too, as they turn into microplastics, which can poison animals and water supplies.

Every year, plastic waste causes around a million seabird deaths, along with the deaths of many, many more animals, especially in marine environments, as a ton of plastic waste – approximately 12 million tons each year, ends up in oceans, rivers, and seas. Even if it isn’t directly choking or trapping animals, microplastic can end up inside their bodies and poison them from within.

Along with all of those wildlife deaths, conventional plastic has many more severe effects on our world. The processes of sourcing the raw materials needed and then processing them into plastics generate lots of carbon emissions, contributing to global warming, which is linked with rising global temperatures, increasing amounts of natural disasters, and other negative effects.

Understanding the full scope of the environmental impact caused by traditional packaging materials is essential for any business considering a shift to greener solutions. Read more about the environmental impact of packaging to learn how choices in materials and manufacturing processes significantly affect our planet.

Can Seaweed Help Solve the World’s Plastic Crisis?

Clearly, conventional plastic is not good news for the natural world. It causes so much devastation, both directly and indirectly, killing wildlife and destroying ecosystems each year. Sustainable packaging solutions, like plastic from seaweed, could be the answer to this crisis, providing a much greener and far less ecologically damaging alternative to the plastics we’ve used for decades.

Seaweed packaging has many advantages. It is derived from natural seaweed sources, supports marine ecosystem health, and reduces reliance on fossil fuels. It also supplies the growing demand for green materials in the packaging industry, proving there are viable alternatives to petroleum plastics. For those reasons, as well as others, it could help to solve the world’s plastic crisis.

That doesn’t mean all plastic pollution and plastic-related issues will cease with the rise of plastic from seaweed and other sustainable materials. Nor does it mean that seaweed packaging is 100% eco-friendly and has no downsides. It still requires energy to produce and dispose of, and it has some limitations, but its benefits far outweigh its downsides.

There are many promising projects already underway regarding seaweed-based packaging. Green leaders in the packaging industry are finding lots of innovative and promising ways to work with this material, like using it for edible packaging, fast food containers, plastic-free food films, poly bags, emulsifiers, polymer sheets, and more.

Seaweed-based packaging is just one of many innovative solutions contributing to a more sustainable future. For a broader perspective on how businesses can implement these practices, explore our guide on eco-friendly packaging options that are transforming the marketplace and enticing eco-conscious consumers.

How to Turn Seaweed into Plastic

Hopes are high that plastic from seaweed could replace conventional plastic in various industries, like food packaging, in the years to come. As discussed above, it brings many advantages to the table. It reduces carbon footprints, supports sustainable aquaculture, and promotes environmental stewardship, to name but a few big benefits.

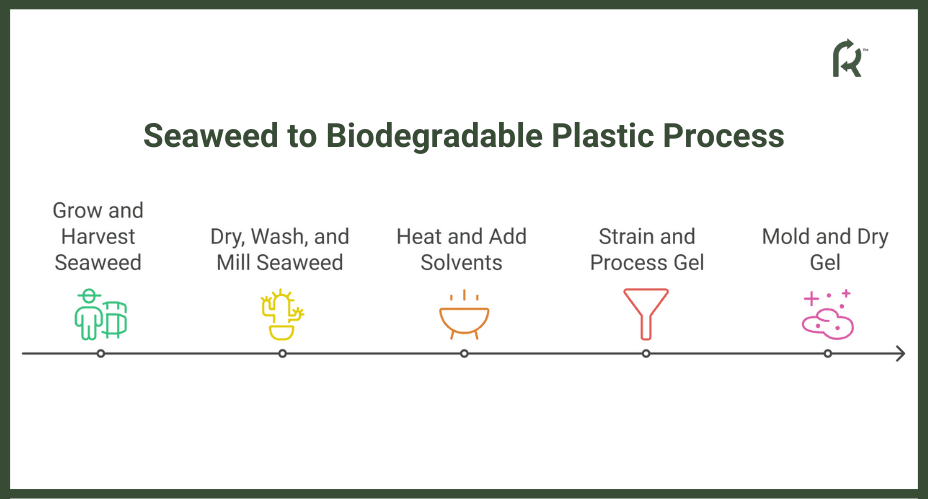

But you might be wondering how, exactly, companies convert seaweed into biodegradable plastics. Here’s a brief step-by-step outline of the process:

- Since seaweed plastic utilizes renewable seaweed resources, the seaweed first has to be grown and harvested.

- It’s then dried out, washed, and milled to remove any impurities and prepare it for processing.

- The seaweed is next heated, and solvents are added, creating a type of gel-like substance.

- This is then strained and processed in an evaporator, which softens the gel.

- The soft gel is then molded and dried, forming plastic-like products without the use of fossil fuels.

Applications of Seaweed as a Plastic Substitute

The rise of seaweed packaging contributes to circular economy practices and enhances eco-friendly packaging options. Plus, there are many ways in which plastic from seaweed can be used in the packaging sector, like:

- Bags – including shopping and poly bags

- Films – to wrap around food items and keep them fresh

- Cups and containers for everyday food and drink items

Seaweed Packaging

Several companies have been experimenting with seaweed-based packaging for food items. This includes edible seaweed cups for drinks and biodegradable and compostable containers, wraps, and films that can store food while it’s being transported and before consumption.

There are a lot of advantages to seaweed food packaging. It’s non-toxic, so it’s perfectly safe to use in close contact with food items, and it has surprisingly strong barrier properties to block out moisture and keep food fresh for longer.

Seaweed Plastic Bag

Through processes like washing, milling, heating, and evaporation, seaweed gel can be formed into environmentally friendly plastic bags, which could someday replace the single-use plastic bags that often end up in landfills all over the globe.

Again, the benefits here are clear to see. Seaweed plastic bags, unlike their conventional counterparts, can be both biodegradable and compostable, so they break down naturally in days or weeks (either at home or in industrial facilities) and don’t release problematic microplastics or toxins into the environment.

Plastic Seaweed Innovations

It’s worth noting, too, that the packaging industry isn’t the only one that could benefit from the emergence of seaweed-based plastic. It has potential applications in an array of other fields, including the automotive and construction industries.

The Chinese automobile manufacturer GAC unveiled a real-life model of a concept car featuring components made of seaweed and other bioplastics at a 2023 auto show. There have also been examples of seaweed-based insulation, which could be used in future homes or buildings.

Advantages of Seaweed-Based Plastic

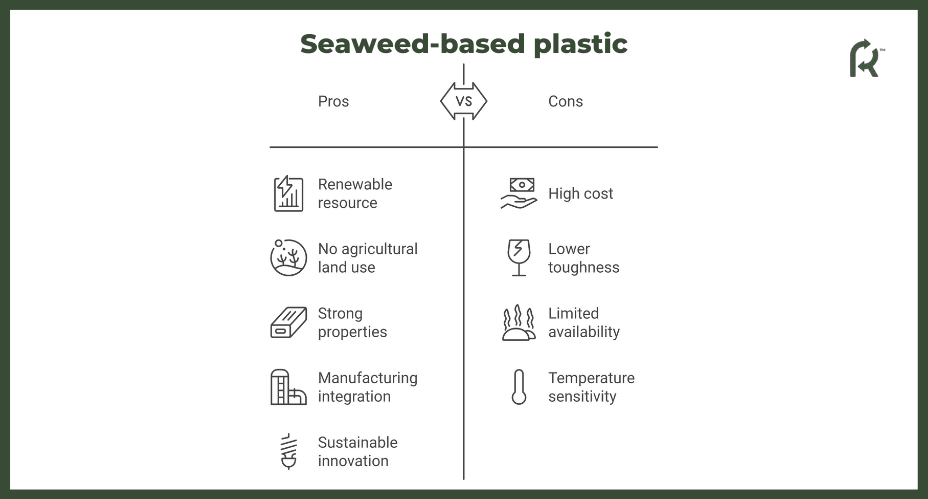

The numerous advantages of plastic from seaweed include:

- It’s made from a completely renewable resource.

- Seaweed grows underwater, so it doesn’t take up agricultural land.

- It has strong mechanical properties, like water resistance and durability.

- It integrates with existing manufacturing processes, which helps with efficiency.

- It promotes sustainable material innovation and provides a viable alternative to plastic.

- Often, it’s a completely edible form of packaging.

- It has relatively low carbon emissions – or “carbon footprint” – compared to plastic.

- It contributes towards lowering levels of plastic pollution.

- It’s biodegradable and often compostable, too.

Limitations of Seaweed Packaging

Seaweed plastic innovates in bioplastic technology and presents a bright future for packaging and other industries. But it’s not perfect:

- Cost-wise, it costs more to make than conventional plastic.

- Despite being strong, it’s not necessarily as tough as certain types of conventional plastic.

- It’s not as widely available or produced in such large quantities as plastic.

- Its sensitivity to high temperatures limits its use in certain applications like hot food packaging, microwave-safe containers, thermal insulation, or transporting heat-sensitive products.

Scalability is also a serious issue with seaweed packaging, as experts predict it could be tricky to cultivate, harvest, and process seaweed at vast enough scales to replace conventional plastics.

With current technology, it would be an incredibly complex and costly endeavor to even attempt this. In contrast, bioplastics like PHA, which are already in use and suitable for mass production thanks to brands like Regen™, are much more readily available and scalable, too.

What Are Seaweed Plastic Alternatives?

Plastic from seaweed is far from the only conventional plastic alternative in use and development today. Various other sustainable packaging solutions are gradually emerging to challenge the dominance of petroleum plastics and prove that safer, greener alternatives do exist and can do many of the same jobs as conventional plastics. They include:

- Bioplastics, like PLA and PHA, are often made with plant oils, starch, and bacteria.

- Hemp, cellulose, and other plant-based packaging materials.

- Paper and cardboard are biodegradable and easier to recycle than plastics.

These materials are comparable to seaweed-based plastics in the sense that they have much lower carbon footprints than petrol plastics and could fuel the push towards a much greener packaging industry. However, they differ in certain aspects. Some offer superior mechanical properties in certain areas, like heat sensitivity, but are weaker in others, like water resistance.

For example, in a direct comparison with bioplastics, like PHA from renewable resources, like Regen™, seaweed plastic falls short in a couple of key areas. Regen™ offers distinct advantages, like the fact that it’s 100% compostable, can integrate easily into existing manufacturing processes, and boasts exceptional levels of durability, making it an optimal solution in numerous industries.

The Future of Seaweed Plastic

Seaweed plastic is still in its infancy, with much room to grow and develop. Looking to the future, we can expect this material to become much more widespread in its usage, not just in the packaging industry but in other fields too.

Companies are continuously uncovering new ways to work with plastic from seaweed, and they may eventually discover more efficient and cost-effective ways to create it, too. This should all help in terms of encouraging more widespread adoption of this material and stronger market integration as a result.

However, there are still challenges to resolve, most notably related to seaweed plastic’s high production costs compared to conventional plastics.

Innovations in PHA bioplastics, like those from REGEN™, are already reducing costs by using locally sourced renewable materials, making them a more financially viable solution for industries looking to transition away from fossil fuels.

Key Takeaways

- Conventional plastic packaging is a huge problem for the natural world, causing wildlife deaths and climate change.

- Seaweed packaging is one of the most exciting and innovative alternatives, with much stronger levels of sustainability.

- Advantages of plastic from seaweed include its biodegradability, edible nature (in most cases), and versatile use cases.

- Startups and innovative brands are looking into ways to work with seaweed plastic to make bags, films, wraps, and more.

- It’s expected that this material, alongside bioplastics and other sustainable solutions, will be part of a push towards more eco-friendly packaging soon.

Frequently Asked Questions

Is Seaweed Plastic Durable?

Yes, plastic from seaweed can certainly be quite a strong, durable, and hard-wearing material, rivaling even the toughest synthetic polymers. It naturally has strong levels of water resistance and is also relatively heat-resistant. This allows it to be used in a myriad of applications and industries.

Is Plastic from Seaweed Biodegradable?

Yes, plastic from seaweed is usually biodegradable, and it usually degrades very quickly, too. There are real-world examples of bioplastics made from seaweed that can degrade in literally a matter of hours when in water, several days in compost bins, or weeks in the soil. The exact timeframe for seaweed plastics to biodegrade depends on the nature of the material in question and its surrounding conditions.

Can Seaweed Plastic Be Recycled?

It depends. In some cases, yes, plastic from seaweed is indeed recyclable, and there have been examples of this already on the market, like seaweed-based films and other packaging products that can be reused after processing in paper mills or other recycling facilities. However, some seaweed-based plastics may not necessarily be recycled – it all depends on their chemical structure and composition.