Plant-based plastics like PHA (Polyhydroxyalkanoates) and PLA (Polylactic Acid) represent a significant step forward in sustainable materials science, offering eco-friendly alternatives to conventional petroleum-based plastics.

Traditional plastics significantly contribute to environmental pollution and greenhouse gas emissions due to their reliance on finite fossil fuels, which persist in the environment for centuries. In contrast, plant-based polymers derive from natural resources such as corn starch, sugarcane, hemp, or algae, making them significantly more sustainable and less resource-demanding.

REGEN™ has set a new standard in bioplastics with its PHA plant-based solutions, with several imperative advantages over conventional and other bioplastics. These include a significantly reduced carbon footprint, renewable feedstock use, and compostability certifications.

Unlike plastics that can persist in landfills and increase microplastic pollution, REGEN™’s PHA undergoes biodegradation efficiently in industrial composting facilities. This process prevents waste accumulation and enriches the soil without leaving toxic residues.

REGEN™’s PHA-based products offer environmental performance and practical usability while promoting circularity and responsible resource use.

What are Plant-Based Plastics?

Plant-based plastics, made from plant-based materials specifically designed to contribute to pollution reduction, present an alternative to traditional petroleum-based plastics. These materials are produced from food waste and agricultural residues, replacing the finite fossil fuels used in conventional plastics.

Bioplastics from renewable feedstocks include PLA (Polylactic Acid) and PHA (Polyhydroxyalkanoates). PLA, usually derived from fermented plant sugars, is widely used in the packaging and production of disposable items due to its compostability under industrial conditions.

PHA, however, is a biopolymer produced by microorganisms. It naturally decomposes in the soil, marine environments, and industrial composting facilities, making them eco-friendly packaging alternatives.

However, not all bioplastics are fully plant-based. For example, PBS (Polybutylene Succinate) can often be partially derived from fossil fuels, emphasizing the need to differentiate between biobased and traditional plastic components.

REGEN™’s PHA-based products address this problem by guaranteeing bioplastics are both certified biobased and compostable. These products fit effortlessly into natural cycles, decomposing in industrial composting facilities without leaving harmful residues. These characteristics position REGEN™ as a leading solution in the growing field of sustainable materials.

Environmental Impact of Plant-Based Plastics

Plant-based bioplastics are a significant step toward tackling environmental issues like climate change, water conservation, and energy savings.

They promote sustainable agriculture in terms of crop rotation and deforestation prevention and significantly contribute to ocean conservation. These bioplastics use renewable energy and low-impact manufacturing to create supply chain sustainability with ethical sourcing.

Plant-based plastics are an innovation in materials science, supporting goals like ecological footprint reduction and pushing for zero-waste initiatives.

Ultimately, they play a role in sustainable urban planning, green building, and even marine conservation, all while supporting energy efficiency and renewable fuel sources.

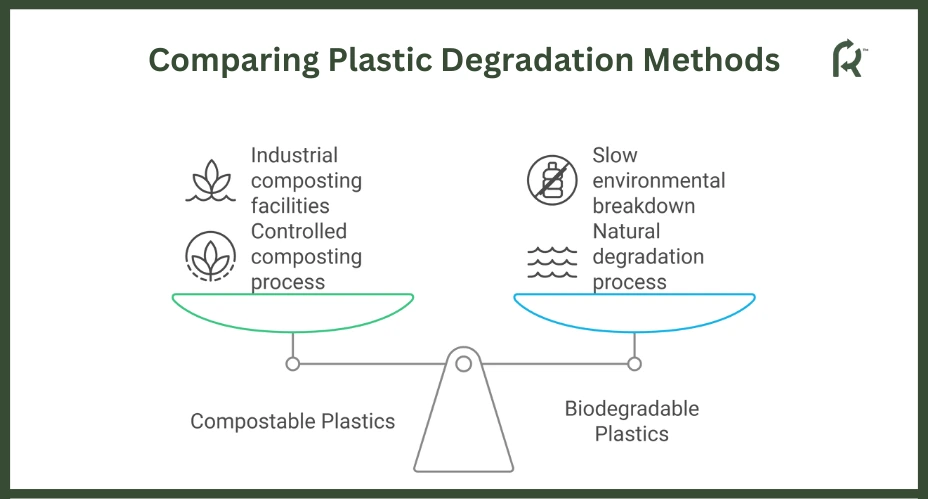

Biodegradability vs. Composting

Though related, compostability and biodegradability differ in the way plastics break down. Compostable plastics, such as REGEN™’s PHA, fully decompose into nutrient-rich compost under specific conditions like those found in industrial composting facilities, where factors like temperature, humidity, and microbial activity are controlled.

On the other hand, biodegradable plastics degrade in natural environments, like soil or marine habitats; however, this process is slower and less controlled than compostable plastics. Understanding this difference is crucial to ensuring proper waste management to preserve the benefits of these materials.

PHA (polyhydroxyalkanoates) is a bioplastic that is both compostable and biodegradable, meaning it naturally breaks down in various environments, including soil and marine settings, and in controlled composting facilities.

In contrast, bioplastics like PLA (Polylactic Acid) are compostable only under industrial conditions. Outside these controlled settings, PLA may persist in the environment.

This versatility makes PHA a superior choice for reducing plastic waste, as its plant-derived nature supports natural ecosystems and lowers greenhouse gas emissions.

Not all bioplastics are biodegradable, but REGEN™’s PHA exemplifies the highest sustainability standards with its dual biodegradability and compostability, making it a truly eco-friendly solution

The Carbon Footprint

Plant-based plastics, especially those created by REGEN™, have a much smaller carbon footprint than conventional petroleum-based plastics, mainly due to their biogenic carbon source.

By utilizing renewable materials such as plant residues, these plastics capture CO₂ during the plant’s growth, which helps offset some of the emissions associated with their production.

Lifecycle analysis shows that REGEN™’s PHA products achieve significant carbon savings, with studies presenting substantial reductions in greenhouse gas emissions due to sustainable sourcing and efficient manufacturing processes. This advantage positions REGEN™’s plant-based plastics as a novel innovation for alleviating climate impact while supporting circular economy principles.

Agricultural Impact and Land Use

Concerns about using land for bioplastic feedstocks primarily focus on the environmental and social impacts. Growing crops like corn or sugarcane for bioplastics can compete with food production, lead to deforestation, and pressure water resources, especially in areas where water is already scarce.

Relying on monoculture farming for these feedstocks can degrade soil health, reduce biodiversity, and make crops more vulnerable to pests.

On the social side, this practice can drive up food prices, displace local communities, and result in inefficient land use compared to renewable energy alternatives.

Approaches like using agricultural waste, getting non-food crops or feedstocks from less productive land, and applying regenerative framing practices can help tackle these challenges. These methods align bioplastic production with environmental sustainability and social responsibility.

Approach to Sustainability by REGEN™

REGEN™ focuses on sustainable manufacturing by sourcing materials locally, which enables cut downs on transportation emissions and strengthens the regional supply chains.

A key innovation is the FlexCarbon™ system, which captures carbon emissions from production and reuses them in the supply chain, reducing waste and lowering the environmental impact.

This system supports the goals of a circular economy by encouraging the reuse of materials and the creation of long-lasting products. It focuses on energy conservation, global warming prevention, inducing habitat restoration, and improving air quality.

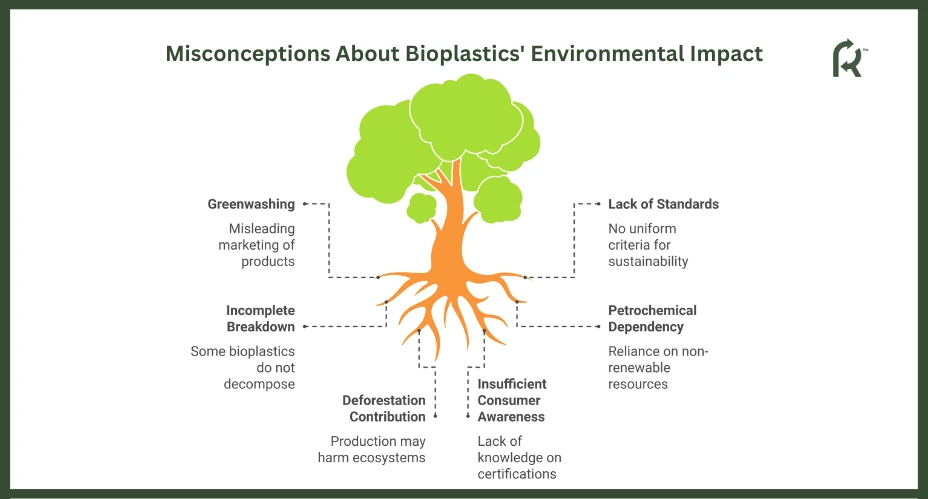

The Myth of ‘Green’ Bioplastics

A common misconception about bioplastics is that they are always a better environmental choice than traditional plastics. While many plant-based plastics are marketed as eco-friendly, they aren’t automatically sustainable.

Not all bioplastics break down properly or are produced under environmentally sound practices, and some may still rely on petrochemical inputs or contribute to deforestation. Consumers should be cautious of greenwashing, where products are falsely advertised as sustainable.

To be eco-friendly, bioplastics must meet specific standards, like compostable or earning certifications such as ASTM D6400 or EN 13432.

Life Cycle Assessment (LCA) is the go-to method for environmental impact assessment because it looks at the technological impact of a product from start to finish, helping make informed, science-backed decisions.

REGEN™ stands out in corporate responsibility by being transparent, focusing on compostability standards, and consumer awareness of environmental regulations of products.

Advantages of Using Bioplastics Over Traditional Plastics

Bioplastics offer several environmental benefits, such as reducing dependence on fossil fuels, lowering greenhouse gas emissions, and decreasing plastic pollution.

REGEN™’s PHA (polyhydroxyalkanoates) is a prime example, demonstrating significant improvements over traditional plastics. Unlike conventional plastics, PHA is less brittle, offering higher durability and excellent resistance to wear and tear.

It also biodegrades much faster, significantly reducing the time plastic waste persists in the environment.

Key Takeaways

- Plant-based plastics, especially REGEN™’s PHA, offer genuine environmental benefits by reducing reliance on fossil fuels and focusing on conservation efforts.

- These waste-to-energy processes in bioplastic production contribute to air quality improvement and forest management.

- REGEN™’s PHA is distinguished by its certified compostability, lower carbon footprint, and use of non-food biomass sources, ensuring it breaks down effectively in composting environments and supports circularity without competing with food production.

Frequently Asked Questions

Is Plant-Based Plastic Healthy?

Plant-based plastics like REGEN™ are non-toxic and safe due to their natural composition from renewable sources like corn or sugarcane. Unlike traditional plastics, they are free from harmful chemicals like BPA and phthalates. These plastics are biodegradable and suitable for various applications, including packaging, household items, and even automotive parts, offering environmental and health benefits.

Is Plant-based Plastic Recyclable?

Not all bioplastics are recyclable, but REGEN™ products stand out because they are compostable, offering an environmentally friendly disposal option. Unlike some bioplastics that may not fit into existing recycling systems, REGEN™ materials break down naturally, reducing waste and supporting sustainable practices.

Is Bioplastic Better Than Recycled Plastic?

Bioplastics like PHA and recycled plastics are essential in reducing environmental impact, but they address sustainability differently. PHA, derived from renewable resources, offers a lower carbon footprint and is both biodegradable and compostable, making it ideal for applications where waste might persist in the environment.

In contrast, recycled plastics are created from post-consumer or post-industrial waste, conserving energy, reducing landfill accumulation, and supporting the circular economy by giving existing materials a second life.

While PHA is an excellent alternative to traditional plastics, especially for single-use items, recycled plastics help close the recycling loop and minimize the need for new material production.

Both options have their strengths: PHA excels in biodegradability and renewability, while recycled plastics maximize resource efficiency and waste reduction. These materials complement each other in creating a more sustainable, circular economy that balances innovation with conservation.