What do you really know about biodegradable plastics? Most people have the basic understanding that these plastics are better for the environment than traditional plastics, but they still don’t understand the opportunities available. You may believe common myths, such as biodegradable plastics being prohibitively expensive, or not understand the facts that show they’re a better option than classic plastics.

For example, petroleum-based plastics have become synonymous with pollution and environmental damage. One reason is that there are over 6 billion metric tons of plastic waste in the world today. That waste won’t biodegrade for hundreds of years, and when it does break down, it becomes microplastics that can harm the environment further. Microplastics end up in the ocean, from which they enter the water we drink.

While biodegradable plastics reduce long-term waste, their production can have environmental costs, such as resource-intensive agricultural inputs for starch-based polymers or high energy demands for manufacturing. The environmental footprint of biodegradable plastics depends on the entire life cycle, from sourcing raw materials to disposal.

- What Are Biodegradable Plastics?

- Types of Biodegradable Plastics

- Common Myths Surrounding Biodegradable Plastics

- Facts About Biodegradable Plastics

- Future Opportunities for Biodegradable Plastics

- Are Biodegradable Plastics More Expensive Than Conventional Plastics?

- Key Takeaways

- Frequently Asked Questions

What Are Biodegradable Plastics?

Bioplastics can be bio-based, biodegradable, or both. Not all bioplastics are biodegradable; some, like bio-PET, are bio-based but not biodegradable. This distinction should be clarified to avoid confusion, as it is a critical differentiation in industry standards.

Bioplastics may also mean plastics manufactured via biological processes, and some manufacturers use the term for biodegradable plastics that may or may not contain petroleum.

Unlike conventional plastics, true bioplastics don’t rely on the limited resource of crude oil, which is the source of petroleum. Many bioplastics break down into component molecules faster than standard plastics. However, anyone interested in environmental welfare needs to note that not all bioplastics are as eco-friendly as they seem.

Many biodegradable plastics contain additives that leverage light and oxygen to help them break down faster than their conventional cousins. Even some petrochemical plastics have these additives. This allows the material to break into its constituent components.

At least 380 million tons of plastics are produced each year, and that volume is growing by 4% year-on-year. Replacing even a portion of petroleum-based plastic production with organic alternatives could have a positive impact on the environment. However, there are many complex factors to consider, including the type of bioplastics and how they’re manufactured.

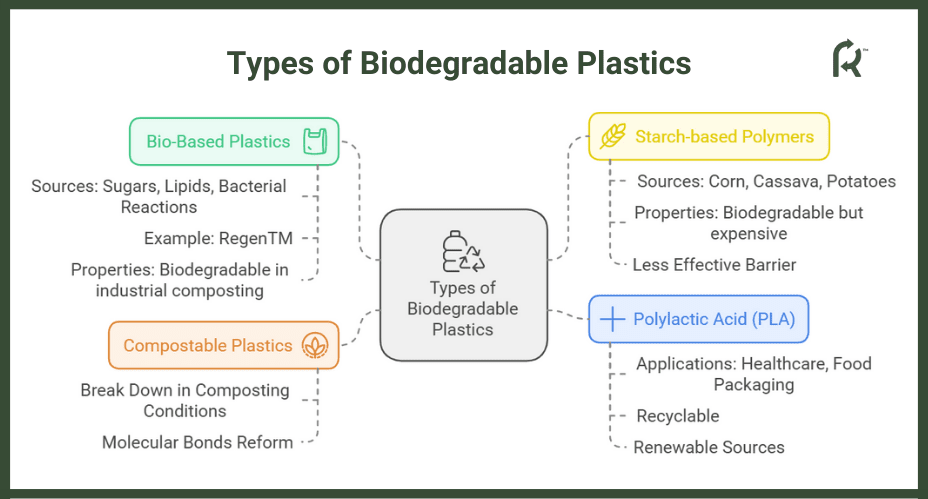

Types of Biodegradable Plastics

There are various types of biodegradable plastics available, with manufacturers coming up with more all the time. Here are some of the available options and their properties.

-

Types of Biodegradable Plastics

Bio-Based Plastics

“Bio-based plastics” refers to any plastic based on a biological ingredient or function. Sources of bio-based plastics include sugars, lipids, and bacterial reactions. These plastics can also come from plant-based fibers or other forms of biomass. Unlike petrochemical plastics, they’re not produced from oil/petroleum, and many are biodegradable.

RegenTM is an example. Certified as bio-based by TUV Austria, RegenTM blends PHA made using bacterial reactions with biopolymers, wood fibers, and natural additives to create a form of plastic that biodegrades in industrial composting sites within six months – Learn More Today.

Compostable Plastics

Compostable plastics will break down in the same conditions as other materials in a composter or industrial compost facility. Warm, moist environments will cause compostable, biodegradable plastics to break their molecular bonds and reform into their constituent components.

Starch-based Polymers

Corn, cassava, and potatoes all produce starch that manufacturers can use to create polymers for packaging. Starch-based polymers are biodegradable but expensive to produce and not as effective at providing a safe barrier as petroleum-based plastics. They also require agricultural products, whereas PHAs, such as RegenTM, don’t.

Polylactic Acid (PLA)

Polylactic Acid (PLA) has been in use in some form since the 1930s. It’s made by heating and manipulating lactic acid and has various applications in healthcare as it’s non-toxic. PLA is also utilized for food packaging. As well as being one of the more popular biodegradable plastics, PLA is recyclable and sourced from renewable sources.

To learn more about PLA as one of the leading biodegradable plastics and its wide range of applications, read our comprehensive article on PLA plastics.

Common Myths Surrounding Biodegradable Plastics

It’s easy to assume that biodegradable plastics could be the answer to all the environmental issues caused by plastic consumption and waste. In particular, the increasing need for single-use plastics for healthcare and hygiene purposes is easier to manage with environmentally conscious alternatives. However, there are several myths surrounding bioplastics that need addressing.

All Biodegradable Plastics Are Created Equal

There are so many different types of biodegradable plastics, and they’re all made in different ways. Some are simple petroleum-based plastics with additives. Others utilize revolutionary new methods of production. Understanding which is which helps buyers and end users assess their environmental impact.

Biodegradable Plastics Solve All Environmental Problems

Biodegradability isn’t the only issue with plastic production. Petroleum-based plastics also cause issues during production as they contribute to global carbon production. There’s also the factor that crude oil is a finite resource.

However, biodegradable plastics also carry environmental impacts. Starch-based polymers require land and water to grow crops, so they may compete with agricultural resources.

The growth of plants for bioplastics may also contribute to water pollution and chemical runoff due to the increased use of fertilizers and pesticides. Producing plastic with oxo/photo-degradable additives can add to the carbon footprint of a manufacturer.

Biodegradable Plastics Are Always the Best Environmental Choice

While the removal of plastic waste is a powerful motivator, the choice to invest in bioplastics requires consideration of the plastic’s use case. If the end-user requirement is for a strong, permanent component or structure designed to last decades, then conventional plastics are the better choice.

Biodegradable plastics are better for replacing single-use items or for use in cases where the plastic would otherwise go to a landfill to sit for decades.

Facts About Biodegradable Plastics

The use of biodegradable plastics is on the rise and the most recent statistics show that globally, manufacturers are producing 2.2 million metric tons of bioplastics each year. That figure is set to rise to 7.4 million metric tons by 2028.

The healthcare, food packaging, and even 3D printing industries use bioplastics. Single-use items such as cutlery, food wrappings, and medical accessories are examples of where bioplastics can reduce non-biodegradable waste.

Plastic being biodegradable doesn’t mean it’s easy to dispose of. PLA, for example, requires specialist facilities to biodegrade into its component monomers to avoid environmental contamination and the formation of microplastics.

It’s safer and less wasteful to recycle bioplastics. However, the recycling process itself can be energy-hungry and contribute to the carbon footprint of the plastic. Choosing certified compostable, biodegradable plastics, such as RegenTM, reduces both financial and environmental costs.

To understand more about how bioplastics can positively impact the environment, explore our guide on the advantages of bioplastics and how they offer sustainable alternatives to traditional plastics.

Diverse Range of Materials

Here are some of the materials classed as biodegradable plastics:

- Polyhydroxyalkanoates (PHA) are polymers made via fermentation that are completely compostable

- PLA

- Bio-based polyethylene (Bio-PE)

- Oxy-degradable/oxo-degradable plastics (both terms refer to plastics with additives so that they break down faster in the presence of oxygen)

- Photo-degradable plastics that break down under UV light

- Starch-based polymers

Degradation Processes

Each of these materials biodegrades differently. Oxo-degradable and photo-degradable plastics fall apart after general use due to reactions with air and sunlight. Unfortunately, studies show that these “biodegradable plastics” are still usable after three years. RegenTM is a superior alternative to these types of plastics as it biodegrades in 180 days or less – Learn More Here.

PLA is recyclable and biodegradable but requires specialist facilities for both processes. However, as most PLA ends up in landfill sites, the necessary processes for biodegradation rarely occur. PLA requires up to 12 weeks of aerobic (with oxygen) composting to break down, which it won’t receive under standard landfill conditions.

Starch-based polymers require enzymic action to biodegrade. However, biodegradation is fast with proper treatment of the material. Blending PLA and starch-based plastics could be a potential way to increase the former’s biodegradability.

PHAs like RegenTM offer true biodegradability as they are compostable in unmanaged environments. In other words, many PHAs can be safely disposed of in standard commercial composters without industrial intervention.

For a more detailed look at how PLA biodegrades and the specific conditions required for it to break down, check out our in-depth analysis on – “Is PLA biodegradable?”.

Environmental Impact

With such a variety of manufacturing and disposal methods, it’s clear that the environmental impact of biodegradable plastics is hardly cut and dried. Creating heat and moisture to dispose of PLA requires energy. Unless manufacturers and waste disposal firms can guarantee that energy comes from sustainable sources, this increases the plastic’s carbon footprint.

Starch-based polymers also offer many environmental challenges. The competition between land to grow food and land to grow plastic is a real dilemma.

While crops used for plastic could represent safer, non-toxic choices for food packaging and other items, they remove space for agricultural growth. The deforestation of land to make way for the materials needed to create starch-based polymers ends up having negative effects on an environment’s ecosystem. Then there are the added chemicals utilized in additional crop growth, which can pollute waterways and decrease biodiversity.

Polymers created by natural processes such as fermentation are a better candidate for a low-environmental-impact polymer choice. PHAs, for example, biodegrade in both soil and water regardless of the presence of oxygen. They’re also easier to produce, thus resulting in a lower carbon footprint throughout the manufacturing process.

Future Opportunities for Biodegradable Plastics

With so many factors to consider, it’s no surprise that the world of biodegradable plastics is evolving. The combined incentives of preventing long-term environmental damage and producing viable alternatives to petroleum-based plastics ensure continued innovation in this field.

-

Advancing Biodegradable Plastics

Innovation in Materials and Technology

Current research into biodegradable plastics revolves around the potential of PHAs. Thanks to the ability to biodegrade in multiple environments, this diverse range of polymers is already utilized for many applications.

Studies are now focused on increasing the variety of situations where PHAs are useful and scaling up the manufacturing process. Techniques such as larger-scale enzymatic processing could see PHAs produced at a rate that challenges current leading bioplastic materials like PLA.

Expansion of Composting Infrastructure

The increased use of PHAs and other biodegradable plastics requires a shift in infrastructure. While these materials are compostable, that’s only a useful environmental factor where appropriate composting facilities are in place.

With the right focus on building and expanding this infrastructure, compostable plastics could become a major aspect of both commercial and industrial enterprises.

Consumer Education and Awareness

Informing consumers about the plastic they already use and those that may become available could help manage the issues surrounding plastic waste. When consumers realize that “biodegradable” single-use plastic bags don’t biodegrade for years, they may switch to a reusable alternative.

Plastic manufacturers should ensure that all products have proper disposal methods provided to aid the conscious consumer in making the right choices. Campaigns to promote the benefits of biodegradable plastics could also aid consumers by educating them on the many options available.

Are Biodegradable Plastics More Expensive Than Conventional Plastics?

Under current manufacturing processes and conditions, it’s more expensive to produce bioplastics than conventional plastics.

There are several factors impacting this, such as the low price of crude oil makes petroleum-based plastic a short-term saving for many large-scale manufacturers.

Many biodegradable polymer production facilities also aren’t running at scale because of the “newness” of the products they create. Research into scaling these operations up and creating more meaningful infrastructural change to support waste disposal and recycling is ongoing.

Once those factors are in play, bioplastics could be far more cost-effective than the oil-based alternatives.

Even with these factors in play, RegenTM offers a cost-effective bioplastic that biodegrades in six months or less per the ASTM D6400 standard. Compare that to the centuries traditional plastics take to biodegrade, and you have a clear choice for sustainability – Check out RegenTM today to discover eco-friendly materials suitable for biodegradable packaging and similar short-term-use applications.

Key Takeaways

- Bioplastics or biodegradable plastics are alternatives to petroleum-based plastics

- They’re not always great for the environment due to the carbon footprint of the manufacturing process, land and water use, or poor facilities and infrastructure to aid in biodegradation

- Without further research into improving infrastructure and scaling manufacturing processes, bioplastics will remain more expensive to produce than oil-based plastics

- PHAs represent a safer, compostable alternative to many problematic bioplastics

Frequently Asked Questions

How Long Do Biodegradable Plastics Take to Decompose?

While some biodegradable single-use bags say they will start to break down in a few days, they can take over three years to biodegrade. PLA can take 12 weeks with monitored aerobic composting facilities. PHA can biodegrade in as little as 58 days.

Are Biodegradable Plastics Always the Most Environmentally Friendly Option?

Biodegradable plastics are, by definition, best for replacing conventional plastics in contexts where unnecessary waste is expected. Single-use items in catering, healthcare, and hygiene settings are ideal applications for bioplastics. However, where permanence and strength and prioritized, conventional plastics are more suitable and environmentally friendly.

Do Biodegradable Plastics Leave Behind Any Microplastics?

Yes, some bioplastics still contribute to the growing volume of microplastics. Oxo-degradable and photo-degradable plastics do because they are conventional plastics with additives. Studies show that bioplastics that break down under UV light are most likely to produce microplastics. Investing in the right facilities and infrastructure to ensure the safe degradation of bioplastics could minimize the further introduction of microplastics into the wider environment.