Biocompatible resins are becoming more popular in high-precision applications, particularly in the medical and dental fields, due to their advantageous properties, such as biocompatibility, mechanical strength, and aesthetic appeal.

These materials are essential for fabricating dental prostheses, orthodontic devices, and various medical components.

The biocompatibility of resins is influenced by their chemical composition, manufacturing methods, and post-processing techniques. Some resins demonstrate favorable biocompatibility profiles, while others raise concerns due to cytotoxicity.

There are different standards for testing the safety and effectiveness of materials for oral care and medicine, both in the preclinical and clinical phases. Factors such as the nature, type, frequency, and duration of contact or exposure must be considered when assessing a material’s biocompatibility.

How Biocompatible Resin Works

Biocompatible is an umbrella term for materials specifically engineered to interact with living tissues without causing an immunological response.

Biocompatibility is “the ability of a material to function in a specific application in the presence of an appropriate host response.” This definition implies a host-material interaction and the material’s expected function. All factors must be balanced before the material can be considered suitable for medical applications and safe for body contact.

The materials compatible with tissue should perform with an appropriate host response. For instance, if the intention is to use the material in contact with the skin for 24 hours, it must be certified to remain chemically stable and not cause an immunological response for that duration.

REGEN™ products are advanced materials designed for precision applications, emphasizing safety and environmental responsibility. They are certified compostable and derived from renewable sources, minimizing their ecological impact. REGEN™ PHA outperforms traditional plastics like polypropylene and bioplastics like PLA in strength and thermal resistance, making it ideal for technical and medical components.

REGEN™ products are tailored for various industries and undergo rigorous testing to ensure biodegradability and safety. REGEN™ bioplastics provide innovative, high-performance solutions that align with sustainability goals.

Types of Biocompatible Resin

Several types of biocompatible resins exist, each with unique properties and applications. The choice of safe resin depends on the specific application and desired properties.

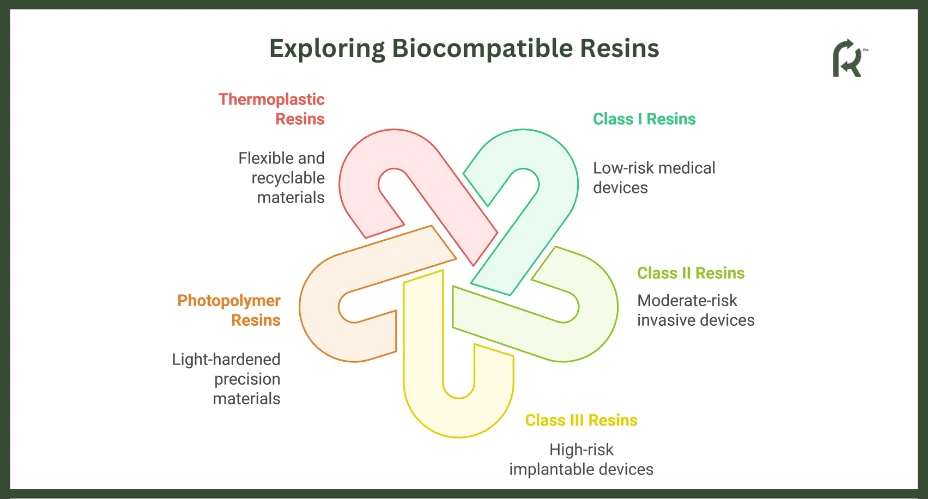

1. Class I, II, and III Biocompatible Resins

Biocompatibility is classified in the US, according to the FDA (and in the EU, according to the Medical Device Coordination Group (MDCG)), as either Class I, Class II, or Class III. The classes are based on the risk of the device.

Class I (only touches intact skin) is a medical device with low to moderate risk that requires general controls. In contrast, Class II (invasive devices) and Class III (implantable devices) medical devices have a moderate to high risk, requiring unique controls.

REGEN™ Bioplastics offers biocompatible materials tailored to the rigorous requirements of industries such as healthcare. REGEN™ materials are designed for safety in sensitive applications, ensuring they are non-toxic, free from harmful additives, and compliant with FDA standards.

2. Photopolymer Resins

Photopolymer resins, which harden upon exposure to light, are pivotal in high-precision industries such as dentistry and 3D printing.

These materials offer unique advantages due to their ability to form complex structures with high accuracy and resolution. Photopolymerization involves converting liquid monomers or oligomers into solid polymers through light exposure, typically UV or visible light.

In dentistry, photopolymerizable resins are used for restorative applications due to their ability to harden quickly and form durable structures. Photopolymerization is a cornerstone of 3D printing technologies like stereolithography (SLA) and digital light processing (DLP).

These methods allow for the creation of highly detailed and precise structures, making them suitable for applications in rapid prototyping, biomedical devices, and tissue engineering.

REGEN™ Bioplastics embodies a steadfast commitment to sustainability, offering innovative bioplastic solutions that align with the dentistry industry’s growing shift toward greener, eco-friendly materials. By prioritizing biocompatibility, biodegradability, and performance, REGEN™ empowers dental professionals to adopt sustainable practices without compromising quality or functionality.

3. Thermoplastic Biocompatible Resins

Thermoplastic resins are known for their flexibility, which can be enhanced through various methods. They are also highly valued for their reusability and recyclability.

Unlike thermoset polymers, thermoplastics can be reheated and reshaped multiple times without significant degradation. This property is particularly beneficial in reducing plastic waste and promoting sustainable practices. The flexibility and reusability of thermoplastic resins make them suitable for a wide range of applications, including high-performance composites and eco-friendly manufacturing processes.

REGEN™ Bioplastics’ PHA is a cutting-edge material that seamlessly combines sustainability, flexibility, durability, biocompatibility, and compostability. By meeting stringent industry standards and advancing environmental goals, REGEN™ PHA offers unmatched advantages for applications across diverse sectors.

What are the Applications of Biocompatible Resin?

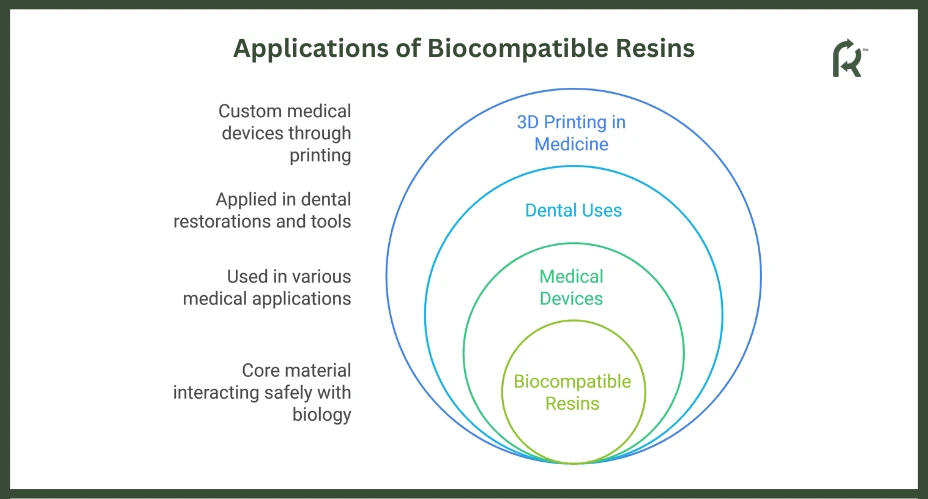

Biocompatible resins have emerged as a cornerstone in various industries due to their safety, adaptability, and environmental benefits. Biocompatible resins are used in various applications, particularly in the medical and healthcare fields, where they come into contact with the human body. These materials are designed to interact harmlessly with biological systems, making them indispensable in fields requiring high precision and compliance with safety standards.

1. Medical Devices

Biocompatible resins extracted from biological systems such as plants, microorganisms, algae, and animals are widely used in drug delivery, cosmetics, wound healing, and tissue engineering. Biocompatible resins are revolutionizing the medical industry by providing safe materials for human use and compliant with stringent regulatory standards.

These resins, as non-toxic materials, are very similar to host tissues. Therefore, they can easily communicate with biological systems. These bio-based materials have many applications in the engineering and regeneration of different tissues.

REGEN™ Bioplastics’ PHA-based materials stand out as a leader in this domain, meeting and exceeding industry expectations. PHA’s ability to degrade into safe byproducts like water and CO₂ makes it ideal for sutures and tissue scaffoldingapplications.

From surgical tools to drug delivery systems, resins like PHA meet sterilization requirements and minimize the environmental impact of medical waste. Please request a sample of Regen’s PHA-based resins for your upcoming project.

2. Dental Uses

Biocompatible resins are used in dental restorations, prostheses, and orthodontic devices. Their compatibility with biological tissues ensures safety and functionality when used in the oral cavity.

In recent years, the use of biocompatible resin-based restorative materials has increased in dentistry because of better aesthetics, improved adhesion to enamel and dentine, and worries about the adverse effects of mercury from amalgam.

REGEN™’s proprietary PHA-based bioplastics bring unique advantages to dentistry due to their precision, safety, and environmental sustainability. REGEN™ materials are made from renewable sources and comply with stringent safety standards, ensuring they do not leach harmful substances into the body. REGEN™ materials can withstand the high-temperature environments often required for sterilization in dental applications.

As a compostable bioplastic, REGEN™ contributes to the circular economy. It allows dental practices to reduce their environmental footprint by using materials that decompose safely at the end of their life cycle. To learn more about REGEN™’s certified biocompatible resins for medical and dental applications, try out a sample for your next project.

3. 3D Printing in Medicine

Integrating biocompatible resins in 3D printing for custom medical devices represents a significant advancement in personalized medicine. The use of 3D printing in medicine continues to grow in both volume and diversity.

3D printing can rapidly create custom devices, which has been adopted by areas of the medical community that require custom solutions. Examples include endoprostheses, temporary dental crowns, epitheses, endoluminal stents, maxillofacial guides, treatment templates, and bespoke repairs. Due to the increase in the use of 3D printing for medical devices to treat patients directly, there is a demand for new materials that provide a variety of biocompatible characteristics for different potential applications.

The REGEN™ PHA filaments are designed for high-resolution 3D printing. Their low brittleness and smooth finish make them ideal for crafting intricate dental devices, ensuring precise fit and enhanced patient comfort. Request a sample of REGEN™’s resins for your next 3D printing project.

Compulsory Regulatory Standards and Certifications

There are clear regulatory requirements regarding the design and manufacture of medical devices to ensure patient safety. Normally, medical devices are manufactured in an industrial production facility with a system of validation, verification, and control methods by quality management systems, such as ISO 13485. Biocompatible materials must be tested and certified in terms of the properties marketed by the manufacturer.

In Europe, biocompatibility is assessed according to the ISO 10993 family of standards, which comprises 22 sections addressing a series of reactivity tests, quality management processes, and risk categorization standards. ISO 10993 is based on the duration and type of contact with bodily tissues and fluids, which matters most when choosing a device material.

The equivalent standard in the US is USP VI (the classification of plastics, biological reactivity tests in vivo), regulated by the U.S. Pharmacopeial Convention, which includes three reactivity tests that must be passed to gain class 6 certification. The three in vivo biological reactivity tests are as follows: acute systemic toxicity (systemic injection) test, intracutaneous test, and implantation test.

REGEN™ products set a high standard in the bioplastics industry by ensuring compliance with certifications like FDA, ISO 17088, ASTM D6400, BPI, and TÜV Austria. Their proven biocompatibility and compostability, backed by studies and certifications, make them a safe and sustainable choice.

Advantages of Using Biocompatible Resin

Made by nature, REGEN™ bioplastic is entirely biodegradable, compostable, and non-toxic. It can be used on standard equipment for numerous plastic applications. Through rigorous testing and adherence to international standards, REGEN™ materials deliver safety without compromising on environmental responsibility.

Challenges and Limitations

While biocompatible resins are revolutionizing industries like healthcare, food packaging, and 3D printing, certain challenges persist. Cost, material properties, and limited end-of-life options often hinder broader adoption.

REGEN™ biocompatible materials, particularly PHA-based resins, provide innovative solutions that overcome these obstacles, ensuring superior performance and sustainability. Biocompatible resins have several drawbacks, including high production costs due to complex synthesis and regulatory requirements for medical-grade materials.

They often exhibit brittleness, limiting their use in applications that need flexibility or durability, and may not withstand high-temperature sterilization or long-term medical use. Additionally, many of these resins, despite being labeled as “biocompatible,” lack compostability or recyclability, raising environmental concerns.

REGEN™ PHA-based resins are biocompatible and compostable, making them ideal for single-use applications in the medical field. They exhibit enhanced properties such as higher tensile strength, flexibility, and thermal stability, which are essential for medical devices like dental tools and surgical instruments.

Additionally, REGEN™ materials are certified compostable and biodegradable, ensuring an environmentally friendly end-of-life option. They comply with global regulatory standards, including FDA and ISO certifications, guaranteeing their safety and reliability for medical and packaging uses.

Key Takeaways

- Biocompatible resins are becoming increasingly important for high-precision applications. Attributes like non-toxicity, precision, and eco-friendliness are essential.

- These resins are engineered to interact safely with biological tissues, making them ideal for applications ranging from prosthetics to surgical tools.

- REGEN™ PHA resins provide a sustainable solution that meets the needs of modern industries while reducing environmental impact.

Frequently Asked Questions

Are All Biocompatible Resins Non-toxic?

Not all biocompatible resins are non-toxic, even though the term implies compatibility with biological systems. Some 3D printing resins exhibit toxicity after post-processing, potentially causing reproductive harm or genetic mutations. Manufacturers must provide users with clear handling instructions to ensure proper use and minimize adverse effects.

Can Biocompatible Resins Be Used in Contact with Skin?

Biocompatible resins are safe for skin contact when designed and tested for such use. These materials meet strict safety and regulatory standards to prevent irritation, allergic reactions, or toxicity during prolonged skin exposure.

Does Biocompatible Resin Have a Long Shelf Life?

Biocompatible resins have a stable shelf life when stored under proper conditions. Their longevity depends on formulation, storage environment, and application. High-quality resins like those from REGEN™ are designed for durability and consistent performance, making them ideal for long-term storage and demanding uses.