The widespread use of conventional plastics, especially polypropylene, has become a major contributor to environmental pollution.

Polypropylene, a petroleum-based plastic, is non-biodegradable and accumulates in landfills, oceans, and natural habitats. To address this challenge, REGEN™ Bioplastics offers sustainable alternatives like polyhydroxyalkanoate (PHA) and polylactic acid (PLA), made from renewable resources and certified compostable.

REGEN™ PHA decomposes quickly under controlled conditions without leaving harmful residues. Compared to traditional plastics, it minimizes environmental impact and outperforms PLA in durability, flexibility, and heat resistance. These qualities make it an excellent choice for packaging and 3D printing applications.

By utilizing renewable materials and innovative technologies, REGEN™ is driving the shift toward a circular economy. Their solutions help industries lower their carbon footprint while meeting the rising demand for sustainable materials, setting a new standard for eco-friendly practices.

Is Polypropylene Harmful for Humans and Wildlife?

The petroleum-based thermoplastic polypropylene is a significant health and environmental hazard because of its dependence on fossil fuels and lack of biodegradation.

Because of its extensive use, plastic contamination in ecosystems persists, landfills accumulate over time, and greenhouse gas emissions occur during production and disposal.

Additionally, the degradation of polypropylene into microplastics raises health concerns, as these particles can enter food chains and negatively impact human and animal health. In contrast, REGEN™ Bioplastics provides sustainable, compostable replacements derived from renewable sources, such as PHA and PLA.

Compared to polypropylene, these materials decompose safely into non-toxic residues, minimizing their adverse environmental effects and eliminating the possibility of microplastic pollution. REGEN™ provides a range of biodegradable materials, such as nylon and polycarbonate, with strength and flexibility without hazardous chemicals or additions.

Top Alternatives to Polypropylene

Sustainable alternatives are becoming more popular in the packaging sector as worries about polypropylene’s environmental effects increase.

The following section discusses some of the best substitutes: environmentally friendly options with comparable performance advantages while minimizing environmental damage.

1. PHA (Polyhydroxyalkanoates)

Polyhydroxyalkanoate (PHA) is a sustainable alternative to traditional plastics, offering environmental and performance benefits. REGEN™ PHA products, derived from plants and renewable feedstocks, are fully compostable and break down into non-toxic residues within 90 days in industrial composting environments.

This property helps eliminate the long-term pollution caused by conventional plastics while enriching soil with organic, nutrient-rich compost. REGEN™ PHA, which comes in various forms, promotes sustainability while providing qualities comparable to the robustness and functionality of materials like paper, glass, and metal.

PHA promotes sustainable product lifecycles by embracing reusable, environmentally friendly alternatives that support a greener future, such as natural fibers like linen, silk, and wool.

2. PLA (Polylactic Acid)

Polylactic acid (PLA) is another versatile and sustainable alternative to conventional plastics. It is widely known for its biodegradability and low environmental impact.

3. Recycled PET (Polyethylene Terephthalate)

Recycled PET (rPET) reduces the demand for virgin materials, repurposes existing plastic trash, and has a lesser environmental impact than polypropylene.

Because rPET uses a well-established recycling infrastructure, it helps divert plastic waste from landfills and the ocean, unlike polypropylene, which is non-biodegradable and excessively dependent on fossil fuels.

Furthermore, rPET considerably lowers greenhouse gas emissions compared to producing new polymers while maintaining exceptional durability and functionality, making it appropriate for packaging and other uses.

4. Cellulose-Based Plastics

Natural and biodegradable substitutes, such as cellulose-based plastics, are a perfect fit for REGEN™’s dedication to sustainability. Made from plant fibers, they are biodegradable and decompose spontaneously without producing hazardous byproducts.

Cellulose-based plastics are both environmentally benign and adaptable. They can replace traditional plastics in various applications, including food packaging and disposable goods. By producing such innovative biodegradable plastics, REGEN™ continues to provide materials that support a circular economy and a healthier planet.

5. Starch-Based Bioplastics

Starch-based bioplastics are a growing substitute for conventional plastics made from fossil fuels, providing a sustainable way to combat plastic pollution.

Because they are biodegradable and compostable, these bioplastics are produced from renewable resources like corn, potatoes, and tapioca, lessening their environmental impact. These polymers, which employ starch as their main constituent, reduce reliance on petroleum-based plastics, which lowers greenhouse gas emissions and plastic waste.

6. Bio-PE (Bio-Polyethylene)

Bio-based polyethylene, or Bio-PE, is a plant-based substitute for conventional polyethylene, a standard plastic usually obtained from fossil fuels. Made from renewable resources like sugarcane, Bio-PE has the same qualities as regular polyethylene but is produced in a more environmentally friendly way that uses less petroleum.

Although bio-PE is not biodegradable, it is highly recyclable. By switching to bio-PE, industries can significantly reduce their carbon footprint and promote a circular economy. This material supports more eco-friendly operations while maintaining the strength and versatility of traditional plastics.

How to Choose the Right Polypropylene Alternative

Sustainable alternatives are becoming more popular in the packaging sector as worries about polypropylene’s environmental effects increase.

This section discusses the best choices that present environmentally friendly options with comparable performance advantages while minimizing environmental damage.

1. Evaluate Environmental Impact

When evaluating the influence on the environment, it’s crucial to prioritize environmentally friendly alternatives to polypropylene. Choosing biodegradable, sustainable options, such as REGEN™ products, guarantees a minor environmental impact and provides a suitable substitute for traditional plastics.

These substitutes, which emphasize biodegradable materials, reduce waste and pollution. Choosing environmentally friendly packaging options, like REGEN™, also supports responsible consumption and reduces resource depletion. By making thoughtful decisions, businesses and consumers may lessen reliance on dangerous, non-renewable plastics and help create a more sustainable future.

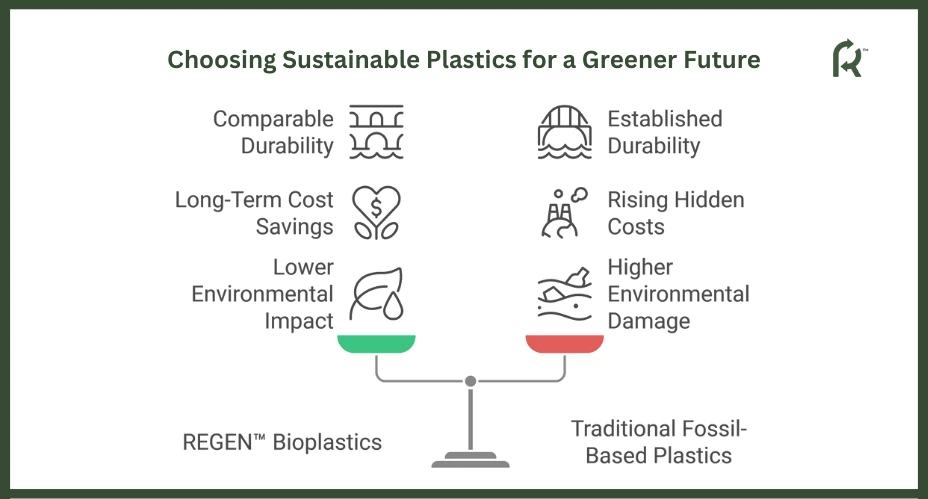

2. Compare Cost-Effectiveness

Even though REGEN™ bioplastics could cost more upfront than conventional plastics made from fossil fuels, they have substantial long-term economic and environmental advantages. REGEN™ goods may eventually compensate for the initial price difference by decreasing the environmental effect and lowering waste disposal expenses.

For instance, REGEN™ bioplastics could be a good fit for the packaging, automotive, and agricultural sectors since they are as strong and long-lasting as traditional plastics. Studies have shown that, over a 5-10-year period, the cost of production for bioplastics can decrease by up to 30% as production scales, while the hidden costs of fossil-based plastics, such as environmental damage and waste management, continue to rise.

3. Assess Performance and Durability

When choosing materials for different industries, performance and durability are important factors. REGEN™ designs their bioplastics to match and surpass conventional plastics’ strength and functionality. Their bioplastics are ideal for packaging food and consumer goods since they provide the same flexibility and impact resistance as traditional polyethylene in the packaging business.

Because of their high tensile strength, REGEN™ bioplastics can be used instead of polypropylene in automobile non-structural parts, lowering weight without sacrificing durability. These bioplastics, made to endure severe environmental conditions, offer durable solutions for various uses while advancing sustainability objectives.

4. Meet Industry-Specific Needs

Consider your industry’s requirements when choosing substitutes for traditional polymers like polystyrene. REGEN™ Bioplastics offers tailored solutions for various industries, such as 3D printing and packaging.

REGEN™ provides eco-friendly, long-lasting packaging materials for plates, cups, bottles, and containers. These materials offer the strength and flexibility needed for product protection and are derived from renewable resources such as hemp, cotton, jute, bamboo, and wood.

Selecting appropriate materials, like those from REGEN™, can help your industry achieve its environmental goals while reducing its dependency on hazardous plastics.

Key Takeaways

The best eco-friendly alternatives are the following:

- REGEN™ Bioplastics: Sustainable, biodegradable alternatives to traditional plastics, offering strength and durability for industries like packaging, automotive, and 3D printing.

- Starch-based Bioplastics: These bioplastics, made from renewable resources, are compostable and biodegradable, reducing plastic waste and reliance on fossil fuels.

- Bio-PE (Bio-based Polyethylene) is a plant-based alternative to traditional polyethylene. It reduces carbon footprints and supports recyclable solutions.

- PLA (Polylactic Acid): Derived from renewable resources like corn, PLA is a biodegradable plastic that can replace conventional plastics in packaging and textiles.

Frequently Asked Questions

Do Sustainable Polypropylene Alternatives Meet Regulatory Standards?

Sustainable polypropylene alternatives, including biodegradable plastics and recycled materials, generally meet regulatory standards. Options like REGEN™ comply with biodegradability and compostability requirements, while recycled materials follow recycling regulations when processed correctly. Certification ensures these alternatives meet safety, performance, and eco-friendly packaging standards.

Is Recycled PET a Good Alternative to Polypropylene?

Recycled PET (rPET) is a good alternative to polypropylene, offering environmental benefits like reduced waste and lower carbon emissions. It is strong and lightweight, making it ideal for packaging. However, rPET lacks polypropylene’s flexibility in some applications and requires specialized recycling infrastructure, which can increase costs.

Can Bioplastics Be Recycled?

Some bioplastics, like Bio-PE and certain PLA types, can be recycled in specialized facilities, while compostable bioplastics like PLA and PHA cannot. REGEN™ bioplastics, both biodegradable and recyclable, reduce waste and support sustainability, offering long-term savings despite higher initial costs.