Though PLAs are developing a reputation as eco-friendly plastics, you may struggle to determine the truth about their compostability and biodegradability. The non-traditional plastic can biodegrade. But it can only do so when placed under specific industrialized conditions.

PLA is a bioplastic made using renewable resources sourced from the natural world. It also has other advantages that make it a green, more sustainable choice compared to conventional plastic alternatives.

How well does PLA biodegrade? What and the conditions needed to break it down? These are some of the key questions about this bioplastic, and it’s crucial to understand the answers before choosing whether to work with PLA or opt for another bioplastic instead, especially for brands with sustainability targets.

This guide will investigate the biodegradability and compostable nature of PLA to highlight how well it breaks down over time.

What Is PLA or Polylactic Acid?

PLA is a bioplastic, which means it’s a plastic-like material derived from natural sources instead of petroleum. It comes from plant sugars, such as corn, sugarcane, cassava, and sugar beet pulp. PLA is one of the most popular and versatile bioplastics, with a broad array of applications like packaging, disposable cutlery, textiles, and 3D printing.

To explore more about the unique characteristics of polylactic acid, including its diverse applications, check out our detailed guide on PLA plastics. You’ll discover more about how they’re made and why REGENTM PHA is an even more environmentally friendly bioplastic.

Our PHA biodegrades in 180 days and enables in-house composting rather than requiring the industrial-grade conditions needed for PLAs. With REGENTM, you get flexibility, improved performance, and a material that is ideal for cosmetic packaging and 3D printing – try us today.

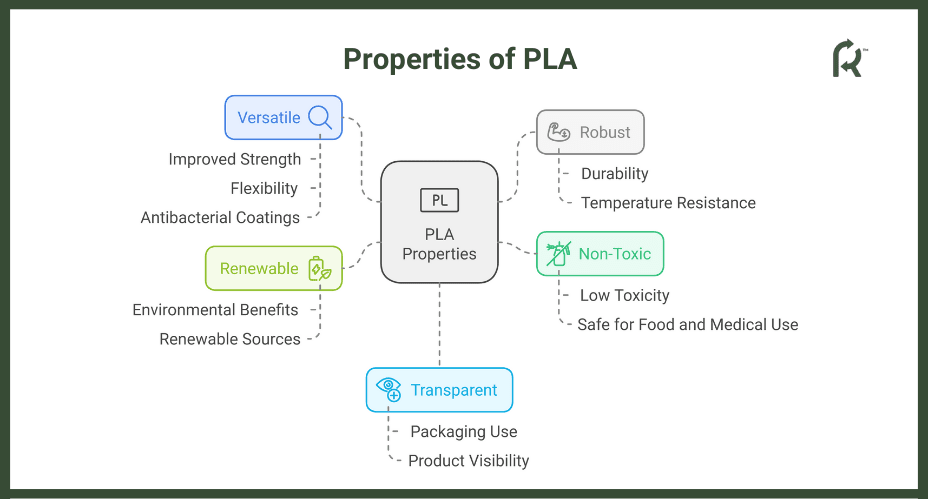

Here are some of the key factors that elevate PLA above other materials:

- Robust: Compared to many other bioplastics and classic plastics, PLA is a strong option. It has impressive levels of durability and can withstand hot temperatures up to its breakdown point of 131 degrees Fahrenheit. Some treated versions of PHA can withstand even higher temperatures, up to 554 degrees Fahrenheit, before biodegrading.

- Non-Toxic: PLA has very low levels of toxicity, especially compared to traditional plastics, which often include harmful elements. Thanks to this, it’s an ideal option for packaging food items and medical equipment.

- Renewable: PLA poses fewer environmental risks than conventional plastics due to its plant-based origins. As the sources are renewable, we can continue making and using PLA for generations to come.

- Transparent: PLA also has the unique property of being see-through. This is one of the reasons why it’s such a popular option for packaging, as it can cover and protect products without obstructing them from view.

- Versatile: Depending on how it’s produced, PLA can have various characteristics, like improved strength, flexibility, or even antibacterial coatings. This unlocks many use cases, ranging from food packaging and 3D printing to use in medical devices like sutures and drug delivery systems.

How Is PLA Produced?

PLA production is a multi-stage process:

- The plant source used to make the PLA—like sugarcane or maize—is grown and cultivated.

- Extraction draws the natural sugars out of the plant matter.

- The sugars break down through a process called hydrolysis.

- The resulting material ferments until it converts into lactic acid.

- The lactic acid molecules join together in chains through the process of polymerization.

It’s a process that boasts strong levels of renewability and sustainability but isn’t perfect. The sugar-rich plants ideal for mass production of PLA require large amounts of agricultural land as well as water and nutrients to grow.

High temperatures and other carefully controlled conditions are also necessary for the hydrolysis, fermentation, and polymerization parts of the process. PLA production also competes with food production as both options use the same resources and ecosystems.

Efforts are ongoing to explore new, more efficient, and environmentally safe methods of PLA manufacture. For example, genetic engineering could produce corn varieties with denser levels of starch content, leading to less plant matter needed to produce the same amounts of PLA. Scientists could also develop new strains of microbes to speed up and optimize the fermentation process.

More advanced catalytic processes may have similar streamlining effects on the polymerization process, and research is also underway to identify alternative sources of biomass to use instead of sugarcane and corn. This research focuses on finding more efficient crop sources that use less land, water, and power to create PLAs.

Understanding Biodegradability of PLA

We’ve seen how PLA offers benefits over traditional plastics. It aligns with sustainability goals for many businesses and helps reduce plastic pollution.

However, the most sustainable bioplastics are biodegradable – able to decompose naturally without doing harm to the environment. Not all bioplastics are capable of this. So, is PLA biodegradable? Let’s take a closer look.

For a broader perspective on how bioplastics contribute to environmental sustainability, you can learn more about the advantages of bioplastics and their role in reducing plastic pollution.

Is PLA Biodegradable?

PLA is biodegradable in so much as it can decompose into non-toxic byproducts. However, the issue of PLA’s biodegradability is a little more complex than it first appears. Other bioplastics, like RegenTM PHAs, for instance, can decompose naturally in water or soil in 180 days – a process that isn’t possible for PLAs. That, for many, is what true biodegradability is all about.

If you’re interested in discovering more about eco-friendly materials that break down naturally, visit our comprehensive guide on biodegradable materials to learn how they contribute to a cleaner environment.

It’s not quite the same story with PLA, as PLA can only break down rapidly when exposed to certain conditions. To create those kinds of conditions, we have to use industrial recycling and composting facilities. There, PLA requires high temperatures above its 131-degree Fahrenheit threshold applied in a controlled environment to biodegrade.

If some PLA products were left in landfills, for example, they wouldn’t have those same kinds of conditions they need to break down. They would still degrade, but it would take a long time – decades rather than months. Due to these specific degradation conditions, PLA doesn’t have the same level of biodegradability as other bioplastics.

Three key factors affect PLA biodegradation:

- Temperature: At greater temperatures, PLA breaks down faster, as the microbes involved in the decomposition process work faster.

- Humidity: In wetter conditions, PLA will also degrade faster as microbes grow, multiply, and work faster with high humidity.

- Oxygen: Aerobic conditions (good levels of oxygen in the air) are better for breaking down PLA than anaerobic environments.

Is PLA Compostable?

Compostable and biodegradable are similar terms, but compostable is more specific. It refers to materials that can break down into compost within a set amount of time. Compostable materials should also enrich the soil in some way and not release any harmful or toxic elements into the environment.

Something that’s compostable should be biodegradable in a way that’s beneficial for the environment. There are also specific standards and guidelines to evaluate if a substance is compostable or not. These standards can vary in different countries around the globe and include the following documentation:

- ASTM D6400: This is the main standard used in the U.S. It’s a four-part test that determines how biodegradable and compostable a material is.

- EN 13432: This is one of the main standards used in Europe, similar to the D6400.

- ISO 14855: ISO 14855 is an international standard that sets out guidelines for testing biodegradation of plastics, bioplastics, and other substances.

- CAN/BNQ 0017-088: This is the standard for Canada, based on the international ISO 17088 standard.

So, does PLA fit the bill? Only to a certain extent. Industrial facilities can compost PLA using commercial composting systems that break the plastic down into harmless natural elements. However, in its current state, it faces challenges in home composting – you can’t put PLA products in a home compost bin like you would certain other bioplastics and expect them to break down.

Is PLA Filament Biodegradable?

PLA filament is one of the most popular feedstocks for 3D printing. It’s almost like plastic wire or thread, and it’s one of the top options in the 3D printing sector because of its eco-friendly nature and versatility.

PLA filament biodegradability is the same as PLA in other forms: it can biodegrade, but it requires appropriate disposal methods and conditions to do so.

As with other types of PLA, PLA filament won’t biodegrade in a landfill or a body of water unless you have decades to spare. It won’t break down in a home compost bin, either. Strict temperature-controlled industrial conditions offer the only efficient method.

The bioplastic starts to break down at temperatures starting from 131 degrees Fahrenheit and requires high humidity and the presence of microorganisms to turn into water and carbon dioxide. This is part of the challenge of working with PLA. It’s got a degree of sustainability, but it’s not the ultimate eco-friendly bioplastic.

However, unlike many other 3D printing filaments, PLA still ranks highly in sustainability stakes. ABS filament comes from fossil fuels and has a huge carbon footprint compared to PLA. PETG is recyclable but not biodegradable and is also derived from fossil fuels. There are also mineable metal filaments, though they demand more energy and resources to make than PLA.

Can PLA Be Recycled?

Yes, you can recycle PLA under certain conditions. It’s similar to how it needs specific composting conditions to biodegrade – it also needs a certain type of environment and specific processes for recycling. You can recycle PLAs either mechanically or chemically, and both methods have their ups and downs.

With the mechanical method, PLA gets shredded and reprocessed into something new. This is the cheaper option, but it impacts the quality of the material over time.

The chemical approach exposes the PLA to chemicals like sodium, tungsten, and iron trichloride, which break the PLA down into its fundamental components, which can then be joined up or mixed with other materials to make something new. This method is more costly.

There are roadblocks preventing PLA recycling from being as simple as it could be. A lot of recycling facilities don’t have the means to work with PLA, and it can get contaminated if mixed with other plastics or substances. Cost is an issue, too, as it’s usually cheaper to source new PLA than to reuse recycled PLA.

How Does REGEN™ Bioplastic Help Fight Against Pollution from Useful Plastic?

REGEN™ is an innovative form of bioplastic from Canada. As a renewable-resource-based plastic, it’s non-toxic and completely compostable.

What’s more, it manages to be a high-performance plastic, too, with excellent mechanical properties like strength, durability, and flexibility, making it a go-to choice for packaging, 3D printing, and more.

- REGEN™ bioplastic provides an alternative to non-biodegradable plastics.

- It supports eco-friendly packaging solutions, thanks to its compostability.

- It has a much smaller carbon footprint than any conventional plastic.

TÜV Austria certifies REGEN™ as biobased, meaning it’s made from renewable resources. Unlike PLAs, these resources aren’t food-based. REGEN™ uses renewable raw materials, such as wood residue from the forestry industry, to create a premium plastic. Discover REGEN™’s potential as a 3D printing and cosmetic packaging material today.

Market Trends in Bioplastic Usage

The bioplastics industry is on the rise and will continue to attract more investors year after year. The market had a $7.49 billion valuation in 2023, with estimates suggesting colossal growth, rising to a value of almost $57 billion by 2032.

That’s a CAGR (compound annual growth rate) of around 29%. More and more businesses are also adopting bioplastics to hit their own sustainability targets and meet customer expectations.

Moving forward, we can expect:

- The bioplastics industry to grow bigger, more valuable, and more influential globally

- New bioplastics to emerge, with even greater levels of sustainability

- Advances in bioplastic manufacturing, helping to improve efficiency and effectiveness

- PLA is recyclable, but the process could use some refinement

Key Takeaways

- PLA is a widely used bioplastic with many advantages for packaging and other applications

- PLA is biodegradable and compostable, but only in specific conditions

- PLA can be recycled, but the process could use some refinement

Frequently Asked Questions

How Long Does It Take for PLA to Biodegrade?

It can, but only at a very slow rate. PLA demands specific conditions, like high temperatures, to biodegrade quickly. In water, it requires the presence of specific types of bacteria and fungi to hydrolyze.

Can PLA Decompose in Water?

Technically, it can, but only at a very slow rate. PLA demands specific conditions, like high temperatures, to biodegrade quickly. In water, it’ll wear down eventually, but the process will take years.

Is PLA Biodegradable at Home?

In its current state, no. PLA requires an industrial setting with the optimal conditions to break down, and it’s not possible to replicate those conditions at home. This could change with the discovery of new breakdown methods in the future.