Imagining a world without plastic today feels impossible. Since the 1950s, the production of synthetic plastics like polyethylene (PET) and polypropylene (PP) has surged, with global demand expected to double in the next 20 years.

Less than 30% of the over 8,300 million metric tons of plastic produced is utilized, leading to about 6,300 million tons of plastic waste by 2015, with 79% entering oceans and other habitats.

This plastic abundance has even been suggested as a geological marker of the Anthropocene era.

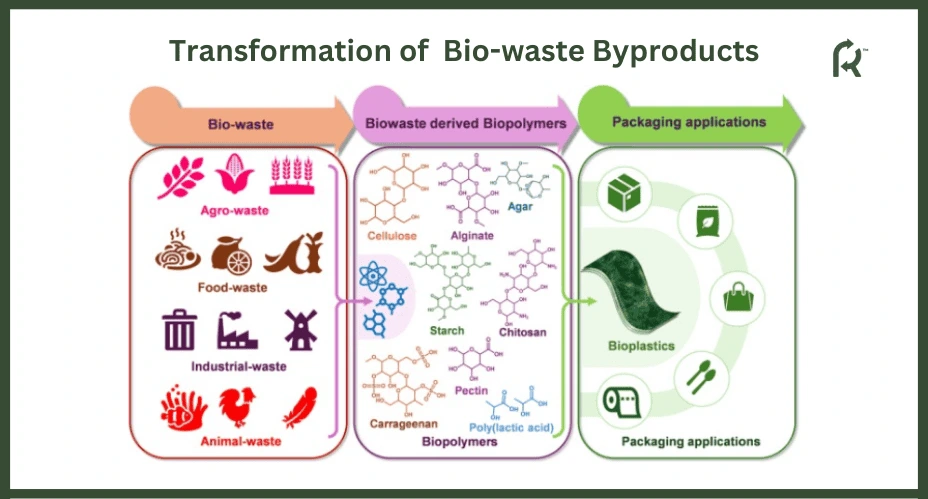

Recent research focuses on eco-friendly plastics and the impacts of microplastics, highlighting the urgent need for biopolymers as sustainable alternatives to synthetic plastics.

What are Earth-friendly Plastics?

Earth-friendly plastics can transform into natural substances over time, breaking down faster than conventional plastics and reducing waste and pollution.

Unlike traditional plastics, which can take centuries to degrade and require destructive thermal treatment, earth-friendly plastics biodegrade without leaving toxic residues, safely absorbing into the soil.

They also minimize the use of fossil fuels—since they’re produced from organic waste—supporting environmental conservation and requiring less energy for production.

Earth-friendly plastic is designed to reduce environmental impact compared to petroleum plastic.

Best Forms of Environment-friendly Plastics

The growing focus on sustainability has heightened interest in recycled and bioplastic materials. Consumers are now actively seeking eco-friendly products, which enhances manufacturers’ brand reputation.

BOSK’s REGEN™ bioplastics offer companies a way to add value while reducing environmental impact. However, terms like biodegradable, biobased, and compostable are often misused and have distinct meanings.

Manufacturers need to understand these differences to market their products accurately, and consumers should be aware of them to make informed purchasing and disposal decisions.

The following subsections will detail various eco-friendly plastics’ features, advantages, and typical applications.

1. Bioplastics

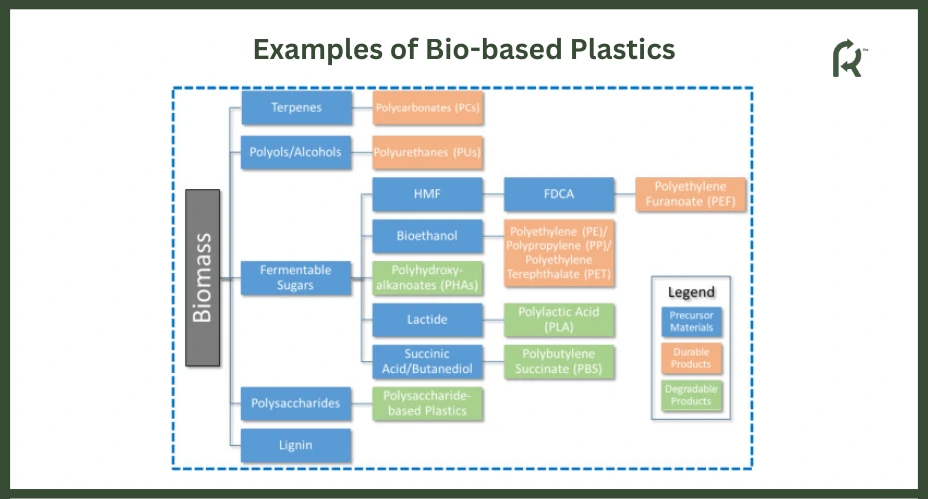

Bioplastics can be classified into three categories: (a) biobased bioplastics, (b) biodegradable bioplastics, and (c) biobased and biodegradable bioplastics.

Biobased bioplastics are the most significant type of plastic resourced from biomass. The biobased but non-biodegradable plastics are bio-polyethylene (Bio-PE) and polysaccharide derivatives, polyol-polyurethane, and bio-poly (ethylene terephthalate) Bio-PET. Examples of biobased and biodegradable plastics are polylactic acid (PLA), polyhydroxyalkanoates (PHA), and poly (amino acid).

Bioplastics serve as cost-effective and eco-friendly alternatives to fossil fuel-based polymers. In 2019, biobased materials made up less than 1% of global plastic production. Renewable resources like potatoes, corn, sugarcane, and microbes can be used to produce bioplastics.

PLA is currently the most-produced bioplastic. It is made from agricultural biomass and is biodegradable. It requires 25–55% less energy to produce than traditional polymers and exhibits excellent thermal plasticity and biocompatibility, though it lacks toughness. PLA is used in applications such as paper coatings, films, fibers, 3D printing filaments, and food packaging.

PHA, a polyester created by bacteria, can be derived from renewable resources, chemicals, and by-products. Based on their monomer structure, PHAs have diverse mechanical properties and are mainly used in packaging, including disposable items like napkins, cosmetic containers, and cutlery.

BOSK’s proprietary PHA is made from the forest industry’s renewable, untapped carbon sources. Through its 100% compostable solution, BOSK aims to significantly reduce plastic waste in the environment.

REGEN™’s PHA is compostable in industrial settings, unlike PLA, which is less biodegradable. Each tonne of bioplastic helps avoid up to 3 tonnes of GHG emissions. Therefore, bioplastics such as PHA from Bosk Bioproducts lessen carbon footprints and reliance on fossil fuels.

2. Compostable Plastics

REGEN™ bioplastic is fully biodegradable in under 6 months at industrial composting facilities, complying with ASTM D6400 standards for products up to 3 mm thick.

This standard ensures compostable plastic breaks down through biological processes, resulting in water, CO2, inorganic substances, and biomass without leaving harmful residues.

Compostable materials were introduced to lessen the reliance on conventional packaging. For example, during the 2000 Olympic Games in Sydney, compostable cutlery helped recover 76% of solid waste by composting waste from nine million attendees.

3. Recycled Plastics

Recycled plastics are produced by reprocessing used plastics through mechanical or chemical methods. This diverts waste from landfills and reduces the need for virgin plastic, which supports a circular economy.

Mechanical recycling, the most common method, involves collecting, sorting, washing, and grinding the material.

Chemical recycling is effective for heterogeneous or contaminated plastics. It converts polymers into smaller molecules and minimizes using chemicals for fuels and virgin plastics. This process can be divided into thermochemical and catalytic conversion methods.

Environmental Benefits of Sustainable Plastics

Implementing simple, cleaner production initiatives in the plastic industry reduces impacts and brings environmental benefits.

Sustainable plastics can have the same characteristics as traditional plastics while offering additional benefits: raw material regeneration, biodegradation, and decreased carbon dioxide production—the chief contributor to global warming.

a) Reducing Carbon Footprints

Bioplastics have dramatically reduced GHG emissions compared to traditional plastics because they are derived using sustainable natural sources.

Biodegradable alternatives like REGEN™ bioplastics can achieve a carbon-neutral or even carbon-negative lifecycle. First, REGEN™’s bioplastics decrease greenhouse gas emissions by replacing fossil fuel derivatives with plant-based fibers and polymers.

This avoids the significant carbon emissions associated with fossil fuel extraction and processing. Moreover, the production process reduces greenhouse gas emissions by capturing methane from organic feedstocks. Locally sourcing raw materials and leveraging energy-efficient processes also minimize the carbon emissions associated with transportation and energy use.

b) Minimizing Waste in Landfills

Products like REGEN™ PHA are certified compostable under industrial conditions. Composting allows these materials to break down into natural components, eliminating the long-term environmental impact of plastic waste and contributing to soil health.

Innovations in Sustainable Packaging by Made With REGEN™

REGEN™ PHA pellets are derived from renewable plant-based feedstocks, reducing reliance on fossil fuels and promoting resource sustainability. They are fully compostable, ensuring safe decomposition at an industrial composting facility under the ASTM D6400 specification. These pellets have better strength, flexibility, and heat resistance than conventional bioplastics like PLA, making them appropriate for various uses.

Made With REGEN™ Approach to Bioplastics

REGEN™ developed a bioplastic that supports a circular economy. In REGEN™’s model, collected industrial waste, such as biosludge from paper manufacturing, is converted into compostable plant-based bioplastics. Therefore, REGEN™ transforms waste into usable products.

Compared to traditional plastics, REGEN™’s PHA is durable, less brittle, versatile, non-toxic, and exhibits better heat resistance, making it suitable for demanding applications.

BOSK’s bioplastics, sold under the brand REGEN™, are biobased, compostable, and compatible with standard plastic manufacturing equipment. Moreover, REGEN™ is a solution to fight against climate change due to significantly reduced GHG emissions.

REGEN™ reduces reliance on petrochemicals and offers a renewable solution for biodegradable packaging that is safe for the environment.

How to Recycle Eco-friendly Plastics

Biodegradable plastics are designed to degrade through natural processes, whereas compostable plastics are certified to break down in industrial or home composting environments.

Clear disposal guidelines for biodegradable plastics are essential, as being biodegradable means it can be discarded in the environment with proper treatment. Greenhouse gas emissions from bioplastics vary widely based on whether they are biodegradable, compostable, or non-biodegradable and their treatment methods.

REGEN™’s products meet strict standards for compostability and are certified with BPI, CMA, and TUV:

- BPI certification is granted following successful ASTM Standard lab tests verified by a third party outside BPI.

- CMA requires and verifies similar lab results internally and conducts field testing in various composting systems to ensure product disintegration.

- TÜV AUSTRIA certifies through lab testing to European standards, which are slightly stricter for heavy metal acceptance.

Key Takeaways

- Traditional plastics made from chemicals sourced from fossil fuels accumulate rather than decompose in landfills or the natural environment.

- Using organic waste from biological origin for bioplastic production reduces our reliance on edible feedstock and effectively assists with solid waste management.

- Most bioplastics have physical and mechanical properties similar, if not better, to conventional plastics.

- The manufacturing and use of bioplastics instead of synthetic plastics reduces the emissions of polluting substances.

- BOSK, leadership in bioplastics, replaces traditional plastic with sustainable alternatives. Sold under the brand REGEN™, BOSK’s proprietary PHA is plastic-free, bio-based, resource-efficient, compostable, and compatible with standard plastic product manufacturing equipment.

Frequently Asked Questions

Are Earth-Friendly Plastics More Expensive Than Traditional Plastics?

Earth-friendly plastics are more expensive than traditional plastics due to factors like raw material costs, complex manufacturing, small production scale, and limited recycling infrastructure.

However, traditional plastics have no economic value after use, with less than 9% being recycled and over 80% ending up in the environment, resulting in significant economic losses.

Can Earth-Friendly Plastics Be Recycled with Other Plastics?

Efficient waste disposal is essential for sustainable bioplastic production. Non-biodegradable bioplastics like bioPP, bioPE, and bioPET can be recycled alongside petrochemical plastics.

Chemical and mechanical recycling is preferable for biodegradable bioplastics, as they help manage waste and recover valuable materials, reducing the need for primary resources.

Are All Bioplastics Biodegradable?

Despite being made from renewable resources, not all bioplastics are biodegradable. Their biodegradability depends on morphology, molecular weight, crystallinity, and local ecosystems. Biodegradation is also influenced by the types of microorganisms present and their activity levels.