The comparison between bioplastics and petroleum-based plastics is increasingly relevant due to environmental concerns such as pollution and climate change. Because they are not biodegradable, petroleum plastics from limited fossil resources significantly increase greenhouse gas emissions and cause long-term environmental damage.

On the other hand, bioplastics, including those created with REGEN™, provide sustainable substitutes. Utilizing renewable resources like PHA (polyhydroxyalkanoates), REGEN™ offers advantages, including compostability, biodegradability, and a much-reduced carbon footprint. REGEN™ is a prime example of how innovation may align with the tenets of a circular economy by tackling the dual problems of resource depletion and waste management.

What Are Bioplastics?

Bioplastics, a type of plastic made from renewable natural resources like cellulose, corn starch, algae, and agricultural byproducts, offer a promising solution to environmental challenges.

These materials are produced using various types of compounds. They are crafted with properties that enable them to perform as well as or better than traditional plastics while significantly reducing greenhouse gases and waste.

With their sustainable life cycle, many bioplastics support recycling or biodegradation, making them ideal as biodegradable plastics for reducing environmental impact.

REGEN™ exemplifies this potential, delivering durable and versatile materials that harness renewable resources to drive eco-friendly solutions. Their work underscores the significant environmental benefits of bioplastics and inspires a greener, more sustainable future for materials science.

What Are Petroleum Plastics?

Petroleum plastics are synthetic polymers, such as depleted polyethylene, polypropylene, and polystyrene, intended for durability and adaptability.

However, their heavy reliance on fossil fuels like natural gas and crude oil depletes these limited resources, accelerating climate change through significant CO2 and greenhouse gas emissions.

Furthermore, petroleum plastics do not biodegrade and remain in the environment for millennia, causing serious problems such as pollution, injury to wildlife, and microplastic contamination in ecosystems and oceans. This alarming environmental impact underscores the urgent need for sustainable alternatives like bioplastics, such as those created by REGEN™, that lessen pollution and environmental hazards.

Bioplastics vs. Petroleum Plastics: Key Differences.

The main difference between bioplastics and petroleum plastics is their source and environmental impact. Bioplastics are made from renewable resources like corn or sugarcane and decompose faster. Petroleum plastics are derived from fossil fuels, are less biodegradable, and have a higher carbon footprint during production. Below is a comparison highlighting their key differences:

| Category | Bioplastics (e.g., REGEN™) | Petroleum Plastics |

| Origins | Derived from renewable resources. | Made from finite fossil fuels. |

| Strength and Durability | Innovations like REGEN™ offer strength and durability comparable or superior to conventional plastics. | Known for high resilience, flexibility, and durability. |

| Heat and Chemical Resistance | Varies; advancements like REGEN™ have improved thermal stability and chemical resistance. | Generally more resistant to heat and chemicals. |

| Environmental Impact | Designed to minimize environmental harm; can degrade quickly under the right conditions. | Contribute significantly to pollution and are less environmentally friendly. |

| Applications | Versatile use in packaging, agriculture, 3D printing, etc. Enhances sustainability in various industries. | Used broadly in packaging, automotive parts, electronics, etc. |

| Carbon Footprint | Significantly lower; uses renewable materials and eco-friendly production methods. | Higher due to reliance on fossil fuels and energy-intensive production processes. |

| Biodegradability and Compostability | Designed to be compostable and break down in industrial composting facilities. | Non-biodegradable, can persist in the environment for centuries. |

| Resource Consumption | Reduces dependency on non-renewable resources, supports a circular economy. | High consumption of non-renewable resources. |

| Cost of Production | Initially more expensive but offers long-term economic and environmental benefits. | Generally cheaper due to established production methods. |

| Market Availability | Growing as demand for sustainable alternatives increases; still less dominant compared to petroleum plastics. | Widely available and currently dominate the market due to lower costs and established infrastructure. |

| Economic Viability | Long-term savings and benefits from waste management and reduced environmental impact make them increasingly competitive. | Cost-effective short-term, but with less focus on sustainability. |

1. Strength and Durability

Petroleum and bioplastics have different mechanical characteristics, and conventional plastics are frequently valued for their resilience to wear, flexibility, and durability.

However, by creating materials that either match or surpass the performance requirements of petroleum-based plastics, breakthroughs such as REGEN™ bioplastics are bridging this gap. Because of their exceptional strength, excellent impact resistance, and improved thermal stability, REGEN™ bioplastics are appropriate for demanding industrial applications.

In certain circumstances, manufacturers design these bioplastics to break down more quickly, significantly reducing their environmental persistence while maintaining functionality. With its strong mechanical properties and environmental benefits, REGEN™ is a key player in transitioning to sustainable materials.

2. Heat and Chemical Resistance

The responses of different bioplastics to heat and chemicals vary; polylactic acid, for example, is less heat resistant and deforms at high temperatures.

However, because of bioplastic developments, such as those made by REGEN™, they may now function in a greater variety of environments due to their increased thermal stability.

Bioplastics can be more susceptible to powerful solvents than petroleum plastics, even though they often handle mild chemicals well. REGEN™ bioplastics, designed to be sustainable and resistant to heat and chemicals, lessen their environmental impact without compromising performance.

3. Suitability for Various Applications

Bioplastics, such as those produced by REGEN™, are versatile and have many applications. They are used in packaging to make biodegradable food containers and films, which helps reduce landfill waste.

3D printing applications also use REGEN™ bioplastics, as their strength and accuracy meet the demands of cutting-edge production.

They enhance environmentally friendly agricultural methods by making plant pots and compostable mulch films. This versatility, combined with their environmental benefits, is driving the increasing use of bioplastics in consumer goods and automotive sectors, with businesses claiming lower carbon footprints and improved product appeal.

Materials like REGEN™, which combine performance and environmental benefits, will drive the global bioplastics market’s growth by more than 17% by 2029.

4. Carbon Footprint

REGEN™ bioplastics have a much smaller carbon footprint than petroleum plastics. Studies show that cutting emissions by up to 80% is possible thanks to renewable materials and eco-friendly production; emissions can be cut by up to 80%.

They’re strong and durable and break down in months under the right conditions, unlike petroleum plastics, which can take centuries. With their blend of performance and sustainability, REGEN™ bioplastics are a smart choice for reducing environmental impact and supporting a greener future.

5. Biodegradability and Compostability

Bioplastics, like those produced by REGEN™, are designed to be compostable. When exposed to the right conditions, they break down into natural elements. These conditions typically involve high temperatures and microorganisms commonly found in industrial composting facilities.

This characteristic contrasts sharply with non-biodegradable petroleum plastics, which can persist in the environment for centuries and contribute to long-lasting pollution. REGEN™ bioplastics offer a sustainable alternative that is more eco-friendly than traditional plastics.

6. Resource Consumption

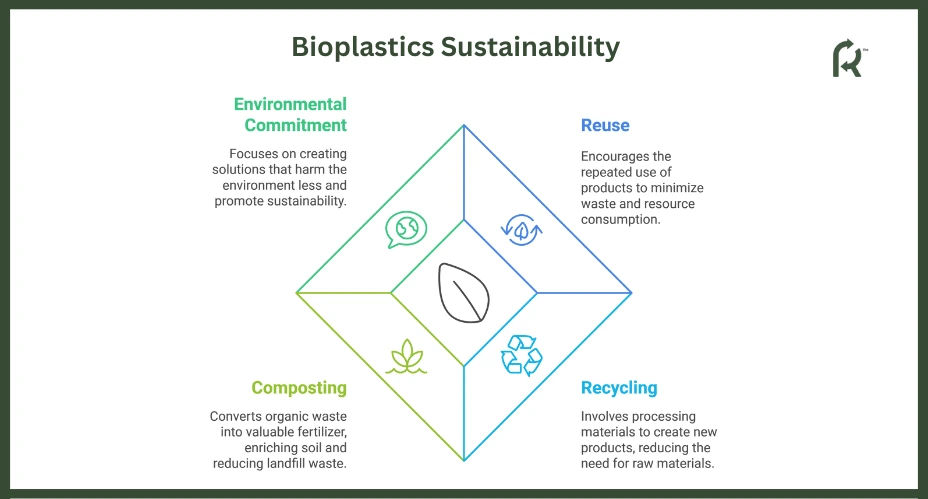

The shift to bioplastics helps reduce dependency on non-renewable resources, promoting long-term sustainability. Scientists design bioplastics for reuse, recycling, or composting, which is part of a circular economy and reduces waste.

REGEN™ is committed to creating environmentally friendly solutions that replace petroleum-based plastics, using resources that can regenerate, reducing environmental harm, and contributing to a more sustainable future.

7. Cost of Production

Although bioplastics can be more expensive initially than petroleum-based polymers, they offer significant long-term economic and environmental advantages.

Decreased waste management expenses repay the original investment in bioplastics because bioplastics frequently compost or biodegrade, simplifying disposal procedures and lowering landfill fees.

To encourage sustainable practices, many businesses that use bioplastics also receive tax breaks or subsidies. Coca-Cola and IKEA have reported reduced waste disposal costs and increased brand value due to employing bioplastics in their packaging.

A 2022 study by the European Bioplastics Organization highlighted that companies integrating bioplastics saw not only environmental benefits but also improved efficiency and customer loyalty, demonstrating the growing financial advantages of sustainable materials.

8. Market Availability

Although petroleum plastics continue to dominate many industries because of their affordability and well-established infrastructure, the availability of bioplastics, particularly REGEN™ products, is slowly growing as demand for sustainable alternatives increases. Despite these obstacles, consumer products, automotive, and packaging sectors effectively incorporate bioplastics into their manufacturing procedures.

Leading companies like Ford and Coca-Cola are reducing their environmental impact by employing bioplastics in car components and packaging. As their market share grows with consumer demand and technological advancements, bioplastics increasingly challenge the dominance of petroleum-based plastics.

9. Long-Term Economic Viability

The growing demand for sustainable materials and bioplastics’ financial advantages drive industries to choose them as a competitive alternative to reduce costs and environmental impact. A 2021 report predicts that the global bioplastics market will surpass $20 billion by 2026.

Innovations like REGEN™, which improve the performance and sustainability of bioplastics, are making them more economically viable. The cost difference is closing as production methods grow more effective and consumer demand for environmentally friendly goods rises.

Businesses like Unilever that use bioplastics have benefited in the long run by reduced trash disposal expenses. In contrast, Ford has reduced overall production costs and environmental impact by using bioplastics in car parts.

Key Takeaways

The main benefits of choosing bioplastics over petroleum plastics are:

- Environmental Impact: Bioplastics are made from renewable resources and are often biodegradable or compostable, reducing pollution and waste compared to petroleum plastics.

- Lower Carbon Footprint: Bioplastics, such as REGEN™, emit up to 80% less carbon during production, helping combat climate change.

- Sustainability: Bioplastics support a circular economy by using renewable materials and reducing reliance on finite fossil fuels.

- Economic Benefits: Bioplastics can eventually lower waste management costs and offer tax incentives, making them cost-effective despite their higher initial prices.

Frequently Asked Questions

Can Bioplastics Completely Replace Petroleum Plastics?

Bioplastics cannot yet wholly replace petroleum plastics due to challenges like higher costs and lower heat resistance. However, innovations like REGEN™ are improving their strength, durability, and affordability. As research and production advance, bioplastics become a viable alternative, offering renewable and eco-friendly solutions for various industries.

Are Petroleum Plastics Still Necessary in Some Industries?

Due to their durability, cost, and adaptability, petroleum plastics are still necessary in the automotive, electronics, and packaging industries. However, bioplastics, such as REGEN™, are improving in strength and thermal stability, suggesting a future where petroleum plastics may be replaced with more environmentally friendly options without sacrificing functionality.

Are All Bioplastics Compostable?

Not all bioplastics are compostable. While some, like PLA and PHA, break down in industrial composting facilities, many bioplastics persist in the environment like conventional plastics. Distinguishing between biodegradable, compostable, and non-compostable bioplastics ensures proper disposal and reduces environmental harm.