In theory, all plastics are degradable, but most petroleum-based plastics degrade at an exceedingly slow pace and are therefore regarded as non(bio)degradable.

Biodegradable packaging is made from plastics that microorganisms can break into biomass, carbon dioxide, and water within a specific timeframe and under certain conditions.

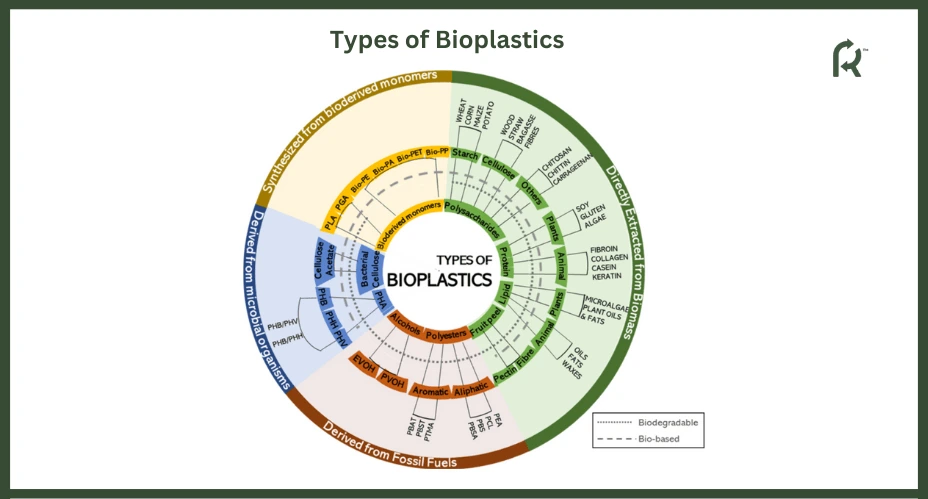

Bioplastics are primarily distinguished by their renewable bio-based feedstocks or their inherent biodegradability, though some are derived from fossil fuels.

They are more sustainable than traditional plastics, emitting fewer greenhouse gases throughout their lifecycle, as the carbon dioxide produced is offset by the carbon absorbed during plant growth.

What is Bio-Based Packaging?

The term “bioplastic” distinguishes polymeric materials that are biobased, biodegradable, or both. It is important to note that not all biobased materials are biodegradable, and not all biodegradable plastics are bio-based. Bio-based plastic is made of substances from living matter or biomass that occur naturally or are synthesized.

The term “biodegradable” is vague as it doesn’t define the time or conditions for degradation. While all compostable materials are biodegradable, not all biodegradable ones are compostable; the former can be broken down into good-quality compost, while the latter may not. Biodegradable bioplastics often have fewer environmental benefits than compostable ones.

“Bio-based carbon content” is assessed through Carbon-14 testing, which determines the percentage of carbon sourced from biomass compared to petrochemicals. Various standards, including EN 16640 in the EU, ISO 16620-2 internationally, and ASTM 6866 in the US, along with certification schemes like TÜV Austria and DIN CERTCO, acknowledge this testing method.

Bioplastics made from compostable and biobased materials are considered greener alternatives to petroleum-based plastics, particularly for packaging. Polylactic acid (PLA) and Polyhydroxyalkanoate (PHA) are notable materials that can replace petroleum-based polymers in various applications.

Benefits of Switching to Biodegradable Packaging

Bioplastic accounts for about 0.5% of annual plastic production, growing primarily in the food and beverage packaging sectors. Companies using biodegradable packaging can enhance their brand reputation, stand out from competitors, and appeal to eco-conscious consumers.

The shift towards sustainability reduces reliance on petrochemicals, supports a circular economy, and lowers carbon footprints. For example, producing 100% bio-based PET from sugar and corn reduces greenhouse gas emissions by 58% compared to traditional petroleum-based PET.

a) Reduces Production Costs

Currently, bioplastic production costs 3 to 5 times more than synthetic plastics. Despite higher upfront costs for materials like REGEN™ PHA, their long-term advantages are significant. Cost reductions can be achieved through cheaper raw materials, improved waste management, biotechnology advances, and enhancements to the properties of biodegradable polymers.

b) Allergen-Free and Non-Toxic

Biodegradable packaging is a safer, non-toxic alternative to conventional plastic, often made from cellulose and starch sourced from food waste. Approximately 50% of bioplastics on the market are starch-based.

This makes bioplastics safe for food packaging as they do not leach chemicals such as bisphenol A (BPA) or affect the taste of the food.

c) Boosts Brand Image

Balancing efficient, affordable packaging with eco-friendly alternatives is challenging.

Consumer preferences are crucial in manufacturers’ decisions, as packaging can significantly impact a product’s success. Biodegradable packaging enhances a brand’s environmental responsibility, fostering positive perceptions among consumers and stakeholders.

This strategic approach is critical to long-term success in a sustainability-focused market.

d) Reduces Carbon Footprint

Companies can significantly lower their environmental impact by using biodegradable materials. Starch-based bioplastics can reduce greenhouse gas emissions and non-renewable energy usage by up to 80% and 60%, respectively.

Fossil-based plastics like HDPE and LDPE emit the highest greenhouse gas (GHG) emissions (2.6–2.9 kg CO2e/kg), while biodegradable biopolyethylene (bio-PE) has the lowest at -1.0 kg CO2e/kg. If PLA does not degrade, its GHG emissions are still about 35%-42% lower than HDPE and LDPE.

Blends of starch with starch residues can cut land use (up to 60%), GHG emissions (up to 10%), and non-renewable energy use (up to 60%).

Types of Biodegradable Packaging Materials

Bioplastics can replace nearly all conventional plastics. The production capacity is expected to grow from about 2.1 million tons in 2020 to over 2.9 million tons by 2025, driven by new bioplastics like PHA and PLA becoming commercially available.

REGEN™ offers a sustainable and eco-friendly alternative to traditional plastics, aiming to reduce global plastic waste. REGEN™’s compostable, bio-based PHA and 3D filaments are ideal for companies looking to boost product value while reducing environmental impact.

REGEN™ promotes a circular economy through innovative technology and sustainable feedstocks.

1. PHA

PHA is a biodegradable bioplastic derived from sustainable resources synthesized by bacteria through microbial fermentation.

It exhibits physicochemical and mechanical properties similar to synthetic plastics. PHAs are highly versatile, ranging from brittle thermoplastics to gummy elastomers, making them potential substitutes for polypropylene, polyethylene, and polystyrene.

Unlike other biopolymers like PLA, PHAs offer superior thermomechanical and barrier properties, making them ideal for packaging. They can be processed for various applications, including packaging, molded products, coatings, nonwoven fabrics, adhesives, and films.

2. PLA

PLA is a renewable, biodegradable thermoplastic polyester made from corn, potatoes, and sugarcane fermentation.

Although it has good mechanical properties, its low thermal stability, brittleness, and high density limit its applications.

PLA is compostable but can remain in marine environments for up to a thousand years. It is commonly used in single-use packaging, such as food packaging, paper coatings, lamination films, and beverage containers.

3. Wood Fibers

Wood fibers, sourced from renewable resources, are ideal for eco-friendly packaging. Often combined with biodegradable polymers like polylactic acid (PLA), these bio-based composites are used in food packaging, agricultural products, and automotive components.

4. Starch-based Bioplastics

Starch-based bioplastics have excellent biodegradation rates, especially when not blended with other materials, making them suitable for composting and environmentally friendly compared to conventional plastics.

Their biodegradability can be affected by the type and concentration of additives used.

Widely used in the food packaging industry, these bioplastics are cost-effective and biocompatible, offering a sustainable alternative to petrochemical packaging while providing good barrier properties against gases and pathogens to extend food shelf life.

5. Cornstarch

Cornstarch-based bioplastics degrade more quickly in natural environments than conventional plastics, reducing long-term pollution.

Adding materials like rice starch, chitosan, and nanocellulose enhances their mechanical properties, such as tensile strength and elasticity, making them suitable for packaging.

These bioplastics are ideal for food packaging due to their biodegradability, ability to maintain freshness, and effective barrier properties against moisture and gases.

6. Cellulose-based Films

Cellulose is the most abundant renewable polymer found in trees and agricultural waste, commonly used in packaging due to its renewability and biocompatibility.

Enhancing cellulose with antimicrobial agents improves its functionality, while incorporating nano- or microfillers boosts mechanical and antimicrobial properties. Bacterial cellulose films produced through biosynthesis provide superior barrier properties and strength.

Additionally, cellulose-glycerol-polyvinyl alcohol films offer improved mechanical properties, water adsorption, and UV protection, making them ideal for food packaging.

7. Seaweed Packaging

Seaweed cultivation is one of the largest aquaculture systems used in biorefineries for bioplastic production.

Seaweed-based films can coat perishable foods to extend shelf life, and their high oxygen and grease barrier properties enhance paper and other packaging materials.

Due to its renewable nature, biodegradability, edibility, and good oxygen/grease barrier property, seaweed is a promising raw material for the development of sustainable food packaging.

8. Bagasse

Bagasse is the fibrous residue left after extracting sugarcane juice. It mainly consists of cellulose (40–50%), hemicelluloses (25–35%), and lignin (25–28%). Bagasse produces significantly lower GHG emissions than plastic and is a sustainable crop that can be replanted in shorter cycles.

Bagasse-based packaging decomposes in months and supports the circular economy by transforming waste into valuable products. It can be used for various items such as food containers, tableware, and cutlery. It offers versatility by handling hot and cold items, resisting moisture and grease, and being suitable for microwaves and freezers.

How to Identify If a Package is Biodegradable

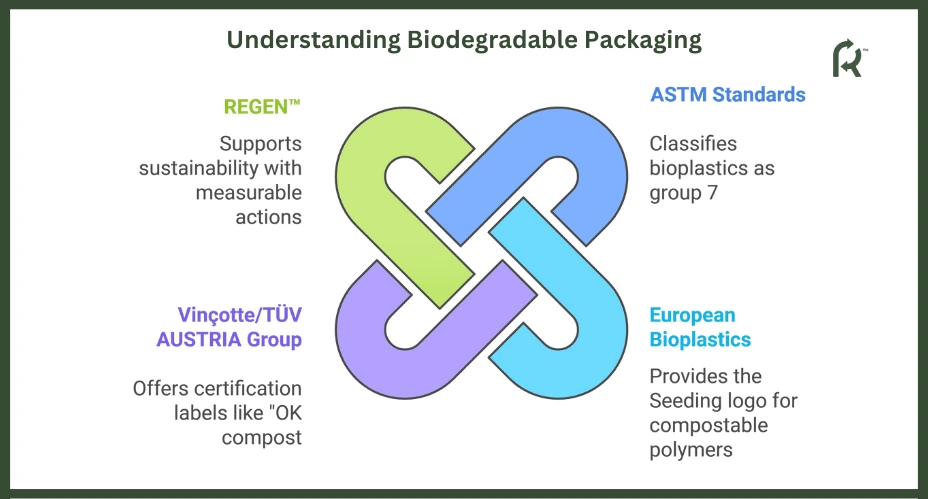

There is no easily identifiable global symbol specifying polymers classified as compostable or biodegradable according to proper standards, such as ASTM D6400, ASTM D6868, EN 13432, ISO 17088, ASTM D5338, and ASTM D5929. The ASTM International Resin Identification Coding System classifies bioplastics and biodegradable plastics as group 7 or ‘other.’

The European Bioplastics created the Seeding logo as a label to identify compostable polymers according to the EN 13432 standard.

Typically, this label is accompanied by another created by Vinçotte, now part of TÜV AUSTRIA Group, such as “OK compost home“or “OK compost industrial.”

REGEN™ is a leader in sustainable materials and prioritizes transparency throughout its journey. REGEN™ supports its environmental claims with measurable actions and verifiable standards, including renewable feedstock sourcing, product certifications, and lifecycle assessments. The compostability of REGEN™ is proven by meeting rigorous compostability certifications (BPI, TUV, and CMA). Transparent sustainability practices build consumer trust and loyalty, establishing REGEN™ as a trustworthy partner.

Cost of Biodegradable Packaging

The bio-based polymers market is rapidly growing, with a production capacity of 2.1 million tons in 2020 and a forecast of 2.9 million tons by 2025.

The cost of biodegradable packaging largely depends on bioplastic prices, influenced by raw material costs, production expenses, consumer demand, crude oil price fluctuations, and regional plastic bans.

Bio-based and biodegradable bioplastics cost between 2.9 to 7.4 USD/kg, while cheaper fossil-based options range from 1.0–2.0 USD/kg but are still pricier than traditional plastics.

The high cost of biodegradable options may limit their use. Localizing feedstock sourcing can reduce import costs and distribution expenses, enhancing the competitiveness of bioplastics in local markets.

REGEN™: A Commitment to Biodegradable Solutions

REGEN™’s PHA production uses industrial untapped carbon sources such as pulp & paper sludges, which are sourced locally and cheaply, reducing supply chain expenses and transportation costs.

REGEN™’s PHA production uses industrial untapped carbon sources such as pulp and paper sludges, which are sourced locally and cheaply, reducing supply chain expenses and transportation costs. REGEN™’s PHA is compostable, eliminating the need for costly landfill or recycling services, and requires less energy to produce than conventional plastics.

REGEN™ is committed to a circular economy and utilizing renewable resources, which solves plastic pollution and contributes to environmental conservation.

Products and Practices

Innovative REGEN™ PHA pellets combine PHA biopolymer with other ingredients (wood fibers, biopolymers, natural additives) to enhance its physical and mechanical properties. They are environmentally friendly and compatible with existing OEM equipment.

REGEN™ PHA pellets are suitable for extrusion, injection, etc., while filaments are for 3D printing.

Products crafted with pioneering REGEN™ PHA are suitable for various industries. These include 100% compostable, 100% free from fossil plastic, and bio-based cosmetic trays and jars.

REGEN™ filaments are stronger, have better adhesion between layers, biodegrade faster, and print as easily as PLA, providing an enhanced experience.

Environmental Impact

As an environmentally friendly business, REGEN™ contributes to reducing carbon footprints and reliance on petrochemical products. REGEN™’s PHA is compostable in industrial settings, unlike PLA, which is less biodegradable.

Each tonne of bioplastic helps to reduce up to 3 tonnes of GHG emissions.

Hydroelectricity powers the majority of REGEN™ production, resulting in nearly zero carbon emissions.

Key Takeaways

- Conventional plastics contribute to climate change by emitting significant amounts of greenhouse gases and solid waste throughout their lifecycle.

- Biodegradable packaging is a sustainable and eco-friendly replacement for traditional plastics. It has a low carbon footprint, reduces reliance on petrochemicals, and supports a circular economy, which boosts brand image.

- Biodegradable packaging materials sourced from renewable resources encompass a variety of innovative options, including PHA, PLA, cellulose-based films, and seaweed packaging.

- PHA, a product by REGEN™ that offers a sustainable alternative to plastic, is designed to minimize environmental impact. It provides several advantages, mainly because it decomposes naturally in composting environments.

Frequently Asked Questions

Is Biodegradable Packaging More Expensive?

The cost of biodegradable packaging remains higher than that of synthetic plastics, but this gap is narrowing as production technologies improve and demand rises.

Energy conservation, avoiding environmental taxes, supplier incentives, and lower waste management fees can lead to long-term savings.

How Long Does Biodegradable Packaging Take to Break Down?

The degradation of bioplastics like PLA and PHA depends on factors such as type, environmental conditions (pH, temperature, moisture, oxygen), microbial activity, and additives.

Due to higher humidity and temperature, PLA degrades more rapidly in industrial composting conditions. It can fully degrade within 30 days in composting, while in landfill conditions, significant fragmentation occurs in about six months, with noticeable disappearance taking around 15 months.

Can Biodegradable Packaging Be Recycled?

The presence of multiple layers and additives in bioplastics makes recycling impractical due to costly cleaning and separation. Composting is a suitable alternative for food waste-contaminated bioplastics, provided they contain no impurities.

While combustion can recover energy from bioplastics, it leads to higher CO2 emissions. Bioplastics like bio-PE can be recycled in the same stream as fossil-based polyethylene.