Plastics are produced at an alarming rate — over 400 million tons per year. Considering most packaging material is made from plastic, that’s a shocking volume of packaging that ends up in landfill sites. It can then take hundreds of years to break down. While this process occurs, plastics contribute toxic materials to the soil, water run-off, and even the air.

Biodegradable materials are a more eco-friendly choice for brands across multiple industries. Using materials like PHA bioplastic that break down quickly reduces the negative environmental impact and helps consumers make sustainable choices.

Understanding which compostable packaging options are the best choice for your company helps you meet rising consumer demands for sustainable bioplastics and other compostable alternatives.

What Are Biodegradable Materials?

Anything that decomposes into its component constituents of water, gases, and biomass can be considered biodegradable. However, it’s important to know these terms when it comes to biodegradation:

- Biodegradable means that a material will break down into water, CO2 (carbon dioxide), methane, and biomass under the effect of microorganisms.

- Compostable means that a material will break down within a certain timescale under specific temperatures and pH levels. The resulting compost can help improve soil. PHAs or polyhydroxyalkanoates, used for many packaging types, are compostable and can have a positive environmental impact. To be designated compostable, materials must pass standards such as ASTM D6400, which covers plastics that can be composted in either municipal or industrial composting facilities. To pass the standard, materials must not create any toxic byproducts or leave unsightly plastic remnants as they break down.

- Recyclable means that the material can be converted into a raw form of itself and remanufactured into something new. For example, polyethylene can easily be reheated and remade into bottles and containers. There are other types of recycling, such as organic recycling, that use waste materials and turn them into entirely new products. For example, food waste, which accounts for 41 million tons of waste in the USA alone, can be recycled into fertilizer or even animal feed.

Popular biodegradable materials include PHA sustainable bioplastics, PLA, and starch-based films, all offering eco-friendly alternatives to traditional plastic packaging.

What Is the Use of Biodegradable Materials?

Biodegradable plastics are already being used in many applications:

- Retail: Some retailers now offer biodegradable bags that claim to break down in 3-6 months like PLA or PHA. However, their biodegradation requires specific conditions, such as industrial composting environments with high heat and microbial activity, and may not occur as effectively in landfills or natural settings.

- Food packaging: The food industry is the top user of plastic packaging, so finding bio-based alternatives is essential to reduce environmental impacts. Starch-based films and other biodegradable packaging materials are now used widely in the food industry. Examples of biodegradable materials include PLA-coated paper, PHA-based films, and starch-based bioplastics, which can break down under industrial composting conditions.

- Healthcare: Single-use items are essential in healthcare to maintain hygiene and safety. Switching to bioplastics for disposable items that professionals can’t reuse helps create a green healthcare sector.

Composting biodegradable plastics could replace recycling as the preferred method thanks to its lower carbon footprint and reduced reliance on landfill sites.

While recycling is a critical aspect of waste management, plastic waste generation is already outpacing the capacity to recycle it. Plus, not all conventional plastics are easily recyclable. Addressing the root of plastic pollution via compostable, biodegradable alternatives is a better long-term solution.

As brands increasingly aim to reduce their environmental footprint, choosing materials that break down quickly is crucial. Discover which materials biodegrade the fastest and offer an eco-friendlier alternative to traditional packaging options.

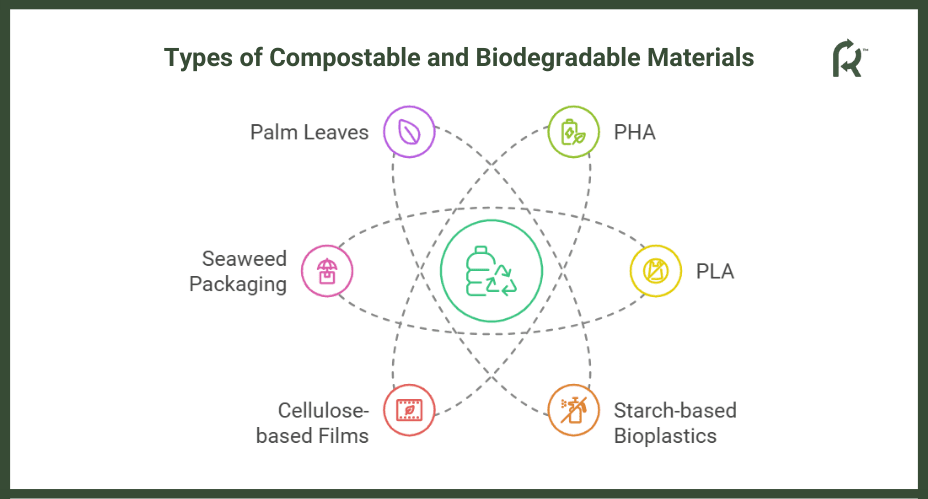

Types of Compostable and Biodegradable Materials used in Packaging

There are now several plastic alternatives that can be composted, or that biodegrade with relative ease. Brands can choose compostable and biodegradable packaging materials that have minimal environmental impact and contribute to sustainability.

-

Types of Compostable and Biodegradable Materials

1. PHA (Polyhydroxyalkanoates)

PHA-based materials are created by allowing sugars or lipids to be metabolized within microorganisms. It’s a process that’s happening all the time in nature, and now it’s been harnessed to produce strong, reliable materials.

Considered environmentally friendly, PHA is produced via renewable, organic feedstock ranging from plant-based oils to agricultural waste. The biological material is introduced to particular microbial strains, resulting in the production of bioplastics.

PHA can be made in many different forms and is usable in multiple applications. Current uses include cosmetic jars, 3D printing filaments with numerous uses, films, single-use products like straws, paper coatings, and even medical implants.

Among the myriad of options available, compostable and biodegradable plastics stand out due to their versatility and lower environmental impact. To understand how these plastics break down and the technologies behind them, you can read more about the developments in biodegradable plastics. This knowledge can help brands make informed decisions about the materials they choose.

Advantages of PHA:

- PHA can be made rigid or flexible depending on the needs of the end-user

- PHA is also very strong

- PHA bioplastics are compostable, so they can reduce landfill waste significantly

- Brands can reduce their carbon footprint by switching to PHA-based packaging by reducing the greenhouse gas emissions caused by the production and conversion of fossil fuels

- This type of bioplastic is non-toxic and doesn’t contribute to soil pollution — in fact, the resulting compost can improve the quality of soil

- PHA bioplastics can be used for 3D printing, making it appropriate for thousands of scenarios

- Importantly, PHA production has the potential to be carbon neutral or even carbon negative by utilizing organic waste as feedstock

Polyhydroxyalkanoates (PHA) are gaining attention for their faster biodegradability and applications across various industries. For a deeper dive into how PHA is being used today and its potential for the future, check out the extensive applications of PHA material. This information could be crucial for brands exploring cutting-edge sustainable packaging solutions.

Pro tip: Brands transitioning to sustainable packaging should consider PHA bioplastics, which offer superior compostability and reduced environmental impact compared to conventional plastics.

-

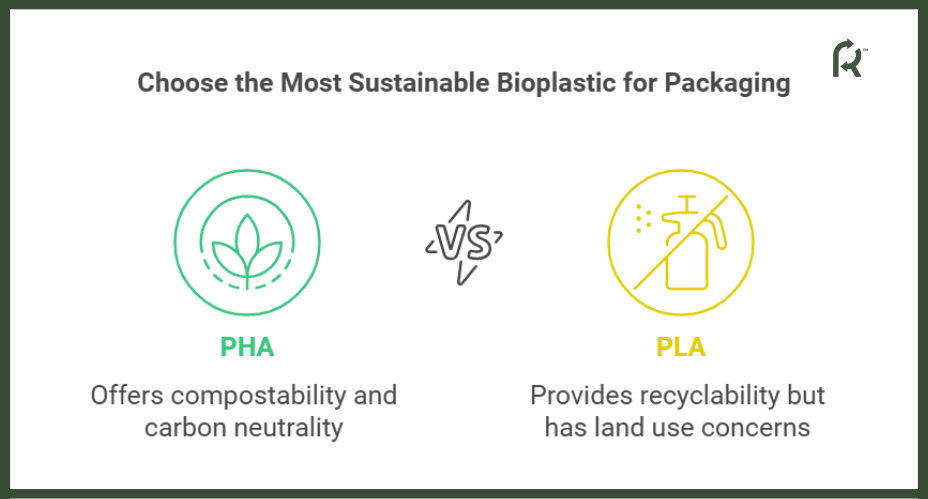

PHA Vs. PLA

2. PLA (Polylactic Acid)

PLA was first discovered in 1932 and is derived from the sugars found in cassava, corn, or sugarcane. The plant material is introduced to heat and sulfur dioxide.

This helps separate out the starch, which is then mixed with citric acid to make polymers similar to conventional plastics. It’s a process called bacterial fermentation and relies on the presence of lactic acids and lactides in the source crops.

PLA enjoys widespread use as a packaging material. Water bottles, food containers, and similar applications are all common. PLA is also recyclable as it’s a thermoplastic, meaning it can be reformed when heated.

Advantages and limitations of PLA:

- PLA can be made to look and feel like crude-oil-based plastics such as polypropylene or polyethylene

- The raw materials used to make PLA are entirely renewable

- The crops needed to create PLA help absorb CO2 from the atmosphere

- However, food-based PLA feedstock also takes up land that could be used for agriculture or reforestation, so net carbon reduction may be impacted

- Growing crops for plastic uses high volumes of water, which also has a negative environmental impact, particularly when combined with the use of fertilizers and pesticides

- Without highly specific industrial composting conditions, PLA can take decades to biodegrade

3. Starch-based Bioplastics

There are dozens of different starch-based bioplastics used across various industries. Starches are polymeric carbohydrates derived from crops like PLA, but the production methods vary for starch-based plastics.

Depending on the type of bioplastic, starch-based materials can be extruded, cast, or molded into various shapes. They are biodegradable but often need specialist intervention to catalyze the process.

The same environmental concerns apply surrounding the use of large swathes of crop-growing land to essentially grow plastic instead of food.

The most common uses of starch-based bioplastics in packaging include:

- Plastic-like films for food

- Single-use items like forks or straws

- Tubs and containers

4. Cellulose-based Films

Cellulose-based film emulates the properties of conventional plastic film but is derived from organic materials. Cellulose is dissolved in chemicals and reformed into a very thin film.

The process is energy-intensive and costly.

New advancements in packaging film include water-soluble aquaplastics. These dissolve in water to the extent that they can be remolded into new shapes for different applications.

Environmental benefits and applications of cellulose films in packaging:

- Cellulose film is biodegradable under the right conditions

- Switching to cellulose reduces the reliance on fossil fuels

- Creating cellulose-based film is expensive and uses high amounts of energy

- Cellulose films don’t block oxygen and moisture as efficiently as conventional plastic alternatives

5. Seaweed Packaging

Seaweed is a natural material found in abundance in both salt and freshwater. These plants are naturally rich in polysaccharides that can be processed to create films and other packaging materials. The process is largely manual and in its early developmental stages.

Properties and benefits of seaweed packaging:

- A biodegradable and compostable packaging material

- Seaweed is widely available and cheap to source

- Strong tensile strength compared to polyethylene

- It may improve soil quality when added to landfill

- Encouraging seaweed growth contributes to cleaner oceans and air

- Expensive to produce at scale due to production and innovation still being in its early stages

6. Palm Leaves

Humans have used palm leaves as plates and food wrappings for thousands of years.

Today, industrial processes heat and steam the leaves, then press them into molds to create durable packaging materials. Most companies manufacturing palm leaf packaging use discarded palm leaves to minimize environmental impact.

Benefits and limitations of palm leaves as an eco-friendly packaging choice:

- Easy to make into plastic-like materials using moisture and heat

- Strong and durable

- Resistant to moisture and freezing

- Microwave safe

- Palm leaf packaging does not biodegrade without specialist intervention

| Did you know? Regen’s PHA breaks down completely within 180 days in commercial composting facilities, leaving no toxic residues, and is proven to degrade even in marine environments, helping brands meet stringent sustainability goals.

Learn more! |

How Does Biodegradation Work?

Biodegradation is an organic process that’s happening all the time. Materials are broken down into simpler components via microorganisms that catalyze the process.

Bioplastic packaging products, for example, are made of complex polymers. Under the right conditions, microbes can cause these polymers to break down into natural elements.

When plastics break down in a landfill, they’re deprived of oxygen which is called anaerobic biodegradation. This produces higher amounts of methane. Aerobic biodegradation means waste breaks down in the presence of oxygen and produces higher volumes of CO2.

For biodegradation to occur, the following conditions must be met:

- The right temperature

- The presence of moisture

- The presence of bacteria or other necessary microorganisms

Plastics like polypropylene aren’t considered biodegradable because, even with these conditions, they won’t break down for decades.

When they degrade, they produce toxic chemicals and microplastics instead of useful biomass. These harm the environments they’re produced in, causing danger to the lives of plants and animals in the area.

The Future of compostable and biodegradable Materials for Brands

As the ability to utilize more types of organic material for plastics increases, expect to see a diverse range of packaging options available. For example, some manufacturers of seaweed-based packaging are investigating the possibility of creating 100% edible packaging.

Technologies that can help break down sustainable bioplastics faster while using less energy will surely be a factor in the future. Innovators will continue to explore ways to create strong, versatile materials like PHA that provide versatile packaging solutions without polluting our planet.

Bioplastics and compostable packaging are essential for a circular economy where manufacturers stop depleting resources and instead work with materials that naturally return to the ecosystem.

Choosing materials that can easily transform into biomass is the right choice for brands that want to resonate with their eco-conscious consumer base.

Key Takeaways

- The continuous use of conventional plastics is harmful to the environment.

- Biodegradable packaging options include bioplastics like PHA and PLA.

- PHA waste products are processed in compost facilities rather than contributing to landfill sites, making them more earth-friendly

- Brands that transform their packaging strategy to include biodegradable materials can reduce pollution, emit fewer greenhouse gases, and move toward a carbon-neutral stance.

Frequently Asked Questions

What Material Is 100% Biodegradable?

Materials like PHA (polyhydroxyalkanoates), bamboo, starch-based films, and palm leaves are 100% biodegradable under proper conditions. PHA degrades in industrial composting, bamboo and starch-based films break down in compost, and palm leaves need specialist composting. Follow manufacturer guidelines for effective biodegradation.

Is Bamboo Biodegradable?

Yes, bamboo is completely biodegradable. It will break down into its components and interact with soil organisms to become a part of the ecosystem once more. However, bamboo requires manual shredding and manipulation to ensure the biodegradation process is efficient.

PHA vs. PLA? Which Is More Biodegradable?

PHA is biocompostable, which means that, under the right conditions, it will break down into water, gases, and biomass i.e. complete decomposition. They are fully converted to organic matter without the generation of harmful substances and help in carbon sequestration. If left to its own devices, a PHA bottle would take less than four years to react with its environment and biodegrade with no traces left behind.

PLA won’t biodegrade under natural environmental conditions but may biodegrade within 180 days under industrial composting conditions.

What Makes a Material Biodegradable?

Biodegradable materials may degrade into smaller fragments, including microplastics or other residues, depending on their composition and environmental conditions. For example, oxo-degradable plastics break down into smaller particles rather than fully converting to organic matter.

Compostable materials, on the other hand, are specifically designed to break down completely into water, carbon dioxide, and nutrient-rich biomass under controlled composting conditions, leaving no harmful residues. Compostability is verified by standards like ASTM D6400 and EN 13432.

REGEN™ PHA-based bioplastics, for example, are non-toxic and compostable. Compostable certifications are regulated by standards like ASTM D6400. PHAs are derived from renewable resources, so they can help move the world toward a circular economy.

What Are the Benefits of Using Biodegradable Materials?

Plastics continuously accumulate in the environment, producing toxic chemicals that different ecosystems absorb. Biodegradable materials matter because they help move away from non-renewable plastics to waste-reducing and sustainable alternatives. They reduce the reliance on landfill sites and help create a more hopeful future free of plastic pollution.

Brands that choose PHA bioplastics from REGEN™ integrate the ability to utilize highly versatile plastics with a more eco-friendly stance. Companies can regenerate their sustainability strategy and mix practicality with an ethical approach to waste management.