You’re searching for a plastic manufacturer in Canada. Not any manufacturer will do – you use this company to create biodegradable PHAs to serve your sustainable plastic needs. Crafted from renewable raw materials like plant oils and sugars, these plastics are much better for the natural world. They are also better for your company’s eco credentials.

PHA plastics utilize microorganisms in production, enabling a natural manufacturing process that creates a plastic that boasts impressive mechanical properties, which open many doors for applications in a rich mix of industries. There’s no shortage of bioplastic manufacturers who have taken up the banner of eco-friendliness to reduce plastic pollution.

The best PHA manufacturers bring innovation to the field of sustainable plastic production and enhance the properties of PHA plastics to make them even more useful both today and in the future.

This guide looks at some of the leading PHA manufacturers in Canada who can meet your sustainable plastic needs, with a brief overview of each one. But first, let’s take a deep dive into what PHA plastics are all about.

What Is PHA?

PHA stands for polyhydroxyalkanoates, which are natural polymers produced by microorganisms like bacteria. These polymers work well as plastic substitutes, when processed and treated in the right ways.

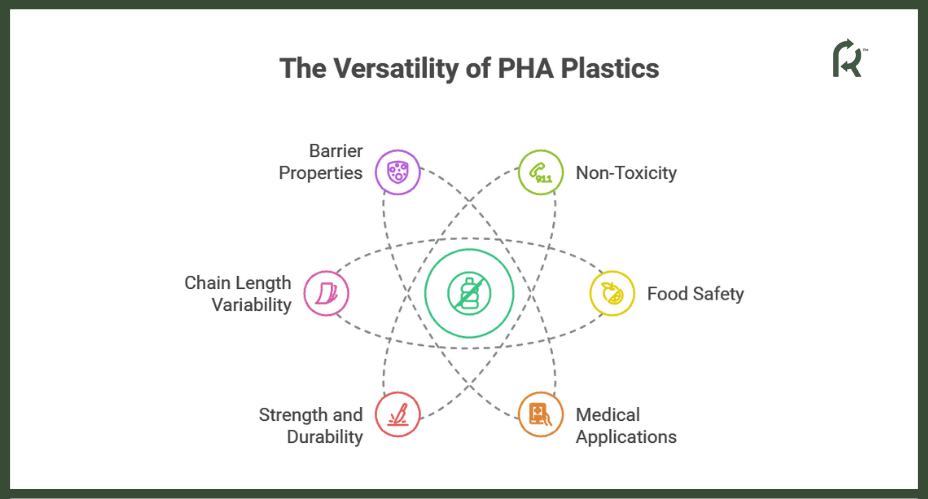

Indeed, PHA plastics are proving to be among the most versatile and efficient of all bioplastics, thanks to their strength, flexibility, non-toxic nature, and biodegradability.

Here are some aspects of PHAs that set them apart from a sustainability perspective:

- Biodegradable: PHA plastics are 100% biodegradable – they break down through microbial activity. Unlike other bioplastics (like PLA), they don’t need industrial conditions to biodegrade. Even in landfills and marine environments, they’ll break down in a matter of months.

- Compostable: You can compost PHAs in industrial facilities, landfills, and even home compost bins. They’ll break down into natural and safe components like water and CO2, which feed soil rather than damaging the ecosystem. The process is quick too, taking mere months in controlled conditions.

- Renewable: PHAs use a byproduct of microbial metabolisms, which manufacturers farm as a renewable resource. That means we can keep on making and using PHAs for years without having to worry about running out of finite resources.

- Recyclable: Research is currently ongoing to discover new ways to break down PHAs for reuse. Through mechanical and chemical methods, we can take old and used PHAs and reshape them into new products.

To learn more about the science behind PHA production and its potential as a sustainable alternative, check out our detailed article on PHA plastics.

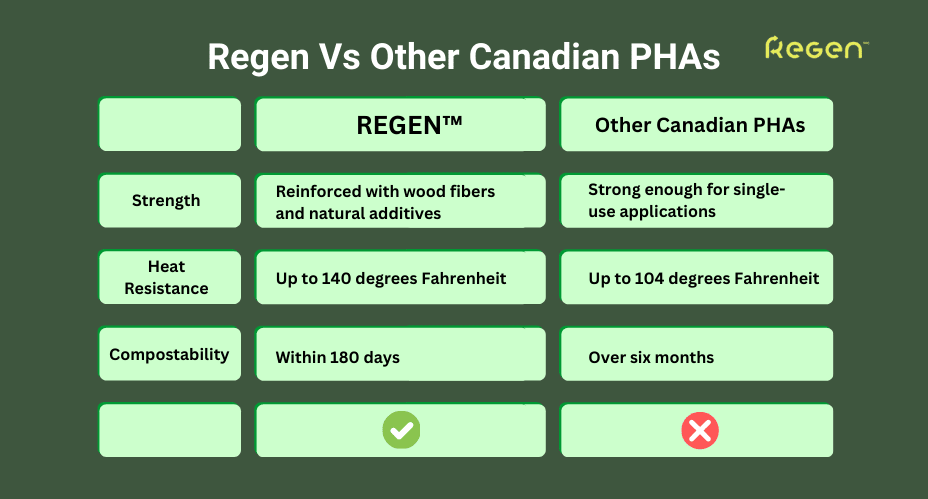

REGEN™’s special PHA blends PHA with ingredients, including wood fibers and natural additives, to create a TUV Austria-approved biobased plastic with impressive strength and flexibility. Find out more about sustainably-produced plastic that biodegrades in 180 days or less today.

How Is PHA Produced?

PHA manufacturers process raw materials into PHA using a multi-stage process:

- Microorganisms (like bacteria) receive renewable resources to feed on. These usually take the form of plant oils or sugars.

- PHA manufacturers then utilize bacterial fermentation techniques to encourage the bacteria to produce PHA.

- With enough PHA created, the bacteria pass through a harvesting process. PHA is extracted and then purified. This purified plastic is what a manufacturer uses to engineer bioplastics for various applications.

- The extracted PHA plastics are processed into usable forms, by means of various production processes.

This entire process is renewable and sustainable. It’s not perfect, as it still requires a certain amount of energy to carry out the various processes and source the materials needed to feed the microorganisms.

But it’s kinder to the environment than traditional plastic manufacturing. Conventional plastics demand fossil fuel extraction, which has a big impact on the natural world, and they aren’t as easy to biodegrade as PHA.

Some of the raw materials, or feedstocks, given to the microorganisms to help produce PHA include:

- Plant oils (like palm and sunflower)

- Industrial waste (like crude glycerol)

- Agricultural waste (remnants of corn and wheat plant matter)

Characteristics of PHA

As touched on earlier, PHA plastics boast a range of great properties that make them so useful and versatile. They’re non-toxic, food-safe, and suitable for medical applications like dissolvable sutures or tissue scaffolds.

They’re also strong and durable, ranking among the few bioplastics that can compete with conventional plastics in terms of pure tensile strength and flexibility. This strength depends on the PHA’s chain length.

A short-chain PHA is brittle and has a low melting point. Medium-chain PHAs are semicrystalline and offer greater elasticity than their short-chain siblings.

Interested in exploring the broader world of eco-friendly alternatives to petroleum-based plastics? Discover the advantages of bioplastics and how they’re reshaping sustainable industries before exploring REGEN™’s innovative blended PHA solution.

PHAs are also known for their barrier properties (the ability to block out moisture and gases). This is part of the reason they’re so good for packaging. Using PHA films and containers to cover up food items or medical devices, for example, will extend their shelf life by guarding them against the effects of moisture and air exposure.

Leading PHA Companies

Now you know what PHA plastic is all about, but who makes this material?

A wide range of manufacturers all over the globe produce PHA bioplastics from renewable resources and develop innovative biopolymer solutions for a brighter, cleaner future. Canada is home to several of the world’s leading PHA companies, contributing to a growing bioplastics sector.

The Canadian government has invested sizable amounts of money into bioplastic development, supporting the efforts of the nation’s leading manufacturers to research new applications for PHA and formulate high-quality bioplastics from local raw materials. This support ties in with Canada’s longstanding commitment to sustainability and caring for the environment.

Let’s take a look at some of the many PHA manufacturers based in Canada, working hard to manufacture biodegradable plastics and distribute PHA products globally.

BOSK Bioproducts

BOSK Bioproducts is a leading Canadian PHA manufacturer based in Quebec City. Specializing in compostable, innovative bioplastics, their aim is to show the world that there are alternatives to conventional, polluting, fossil fuel-based plastics to usher in a brighter and cleaner age of bioplastic usage.

The company’s signature product is REGEN™, a PHA-based bioplastic supplemented with additional biopolymers and natural ingredients to enhance its properties. REGEN™ is non-toxic, bio-based, compostable, versatile, and boasts levels of strength and flexibility that can rival even the toughest of traditional plastics.

- BOSK aims to improve the biodegradability of plastics through research and experimentation.

- Their products meet industry standards and regulations.

- Their research teams strive to commercialize renewable biopolymers to contribute to the fight against climate change.

- BOSK’s REGEN™ plastic offers 3D printing and cosmetic packaging applications.

REGEN™ isn’t any old bioplastic. It’s ASTM D6400-certified for compostability, breaks down within 180 days of use, and surpasses most PHAs in terms of its strength and flexibility. That’s a result of BOSK’s blending process, which incorporates natural additives and wood fibers into REGEN™.

PolyFerm Canada

PolyFerm Canada is another of Canada’s leading PHA manufacturers, who focus on the use of green thermo elastomers instead of petrochemical-based plastics.

Their products (medium chain length PHAs, or MCL-PHAs) come from renewable feedstocks like plant sugars and oils. These products are biodegradable, high-performing, and suitable for use as plastic additives, inks, adhesives, paints, and biomedical supplies.

TerraVerdae Bioworks Inc.

TerraVerdae Bioworks is a leading specialist in PHA polymer development, creating products like film resins, injection molding resins, adhesives, and bioplastic coatings, all based around PHA plastic technology.

Innovation is a big part of TerraVerdae’s philosophy, and the company has a proven track record of developing new types of PHAs. It also invests in sustainable technology and collaborates with research institutions to deliver the most innovative and impactful PHA products.

Genecis Bioindustries

Genecis Bioindustries is one of the many Canadian PHA manufacturers to supply eco-friendly packaging materials like bags, wraps, and containers. The company also creates automotive and textile products from PHA bioplastics, medical tools, and single-use goods.

It’s one of the nation’s leading lights in eco-friendly PHA manufacture, researching ways to use organic waste materials as the primary feedstock for production. In other words, it can take waste and turn it into usable plastic – a very exciting prospect for the future.

Good Natured Products

Good Natured Products is a long-running bio-based manufacturing firm that has been using PHAs and other biological polymers to produce a diverse assortment of packaging products for food, drinks, and more since 2006. The company commits to making bio-based packaging more affordable and accessible for businesses.

It has production facilities spread out across North America, with some in Canada and others in the U.S. This allows it to scale production to meet demand, creating quality bioplastics in varying quantities for businesses in manufacturing, retail, and beyond.

Applications of PHA in Various Industries

We’ve met some of the top PHA manufacturers in Canada today. But you might be wondering about how and where PHA plastic is actually used. The answer is that there are many uses because PHA’s versatility, mechanical advantages, and biodegradability make it a fine fit in a huge range of different industries and sectors:

- Packaging: The No. 1 use of PHA plastics at the moment is in packaging. Whether used in bags, boxes, liners, or containers, PHAs can adapt to an item’s shape and be processed into all sorts of forms to cover and protect products. They’re used for food packaging (more on that below), as well as containers for consumer goods like electronics, toys, and gifts.

- Agriculture: PHA plastic provides game-changing applications for farming. For example, it’s used to make mulch films that cover the soil to protect against erosion and nutrient leaching. PHAs can also line seedling pots, helping young plants to grow and thrive, then feed the soil naturally when they break down.

- Biomedicine: PHAs have unique characteristics like biocompatibility (they don’t tend to trigger adverse reactions when used in medical implants) and biodegradability (they can break down naturally in the human body) that make them ideal for use in medicine. They’re great for dissolvable sutures, tissue scaffolds, and targeted drug delivery systems.

- Food and Drink: PHA is generally considered a food-safe bioplastic. It’s used to package, protect, and cover up everyday foodstuffs without harming consumers. PHAs are increasingly used in food packaging, like bags and wraps for fruits and veggies, as well as for disposable cutlery and drinking straws.

For a more detailed overview of how PHAs apply across diverse industries, explore our in-depth guide on PHA material applications, where we cover their usage in packaging, biomedicine, agriculture, and more.

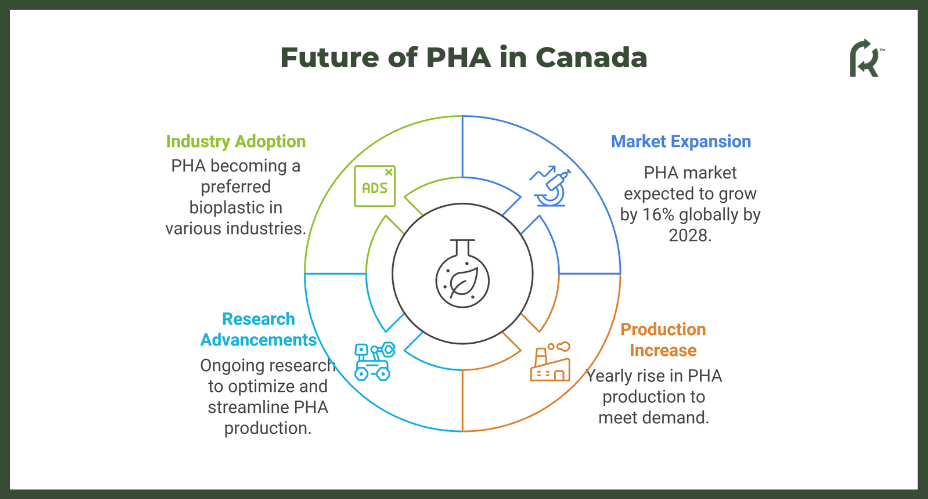

The Future of PHA in Canada

It’s a bright and exciting time for PHA plastics in Canada and beyond, thanks to the government investing in bioplastic production, increasing levels of regulation to reduce conventional plastic usage and pollution, and rising levels of consumer awareness around what bioplastics are and the benefits they bring.

All these factors should contribute to a surge in the usage of PHA (and other bioplastics) in the years to come.

- The global PHA market will grow by almost 16% between 2023 and 2028, which indicates how acceptance and application levels of these bioplastics are rising.

- PHA production levels are also rising year on year to meet the high levels of demand for bioplastics in packaging, medicine, and beyond.

- Research is ongoing to optimize production processes for efficiency, making PHA production (and the creation of other bioplastics) more streamlined and less wasteful.

- This research could uncover new methods to make, use, and even dispose of PHA that are more efficient and eco-friendly than those that are currently in use.

- We can expect PHA to become one of the de facto bioplastics of choice in industries as varied as food packaging and the medical sector as it continues to prove itself a versatile, strong, and flexible option.

Work with REGEN™ to discover the true potential of Canada’s PHAs. You’ll discover an eco-friendly plastic solution ideal for cosmetic packaging and 3D printing. Learn more today.

Key Takeaways

- Bioplastics (natural, renewable plastics) are taking over from conventional plastics.

- PHA is one of the top bioplastics at the moment, offering many unique advantages.

- Leading PHA manufacturers produce this material for use across many industries.

- Many top PHA manufacturers, like BOSK Bioproducts, call Canada their home.

- PHA is used in medicine, packaging, food, and several other industries, with new potential applications discovered regularly.

Frequently Asked Questions

Are PHA Plastics Fully Biodegradable?

Yes, studies and scientific research have proven that PHA plastics are 100% biodegradable. They can break down into their core, natural and ecologically safe components like carbon dioxide and water via microbial action, in a matter of mere months. What’s more, specific controlled or industrial conditions are not required for this process to take place. PHAs can break down in regular landfills or even water.

Can PHA Be Used for Food Packaging?

In the vast majority of cases, the answer is yes. PHA is food-safe and non-toxic, containing nothing but safe, harmless components. It also doesn’t pass any kind of aroma or taste onto food items. Thus, it’s used in the food packaging industry for items as varied as yogurt pots, candy wrappers, and even disposable, single-use spoons and straws.

How Do Canadian PHA Manufacturers Contribute to Sustainability?

Canadian PHA manufacturers lead the way in PHA and other bioplastic manufacturers for a more sustainable world. Brands like REGEN™ also aim to push the boundaries of what PHA plastics could be by combining them with other biopolymers. Meanwhile, other Canadian firms like Genecis are researching ways to use organic waste to make novel bioplastics.