The demand for sustainable packaging is growing rapidly due to increased public awareness of environmental issues, regulatory pressure, resource depletion, and the need for businesses to meet sustainability goals.

Plastic packaging is prevalent due to its lightweight nature, impermeability to gases and moisture, and cost-effectiveness. However, plastics’ non-biodegradability, poor heat resistance, and toxic softeners contribute to environmental pollution and associated detriments.

According to a UN report, approximately 299 million tonnes of packaging materials were produced in 2013, with only 43% adequately disposed of. Therefore, demand for traditional petroleum-based plastics is declining due to their harmful environmental impacts and health risks.

The urgency of mitigating traditional packaging materials’ environmental impact has steered research toward developing sustainable food packaging solutions. Sustainable packaging also enables brands to differentiate themselves and appeal to increasingly environmentally conscious customers.

What Is Sustainable Food Packaging?

Sustainable food packaging meets the growing demand for environmentally responsible products by reducing waste, conserving resources, and reducing greenhouse gas emissions.

New materials and technologies, such as biodegradable and compostable biopolymers made from plant-based plastic, are being developed to enable more efficient recycling and composting.

Innovative Sustainable Food Packaging Solutions

There is a growing trend towards using more sustainable packaging solutions, such as biodegradable packaging, compostable materials, edible packaging, and recyclable alternatives. Each option offers distinct advantages, such as environmental sustainability, cost savings, and enhanced brand image. This trend aligns with the food industry’s goal to reduce waste while promoting corporate responsibility.

1. Compostable Packaging

Compostable packaging, primarily composed of natural fibers, has gained significant traction, promising to enrich the soil with valuable nutrients as it degrades. Compostable packaging is a small subset of biodegradable packaging that can decompose under composting conditions and within a relatively short period.

Namely, all compostable products are biodegradable, but not all biodegradable products are compostable. The bioplastics industry often uses two categories of compostable products: industrial-composting products that degrade at ∼58 °C and home-composting products that degrade at ∼28 °C. In general, all home-composting bioplastics can readily degrade under industrial composting conditions.

PHA is fully compostable and biodegradable; its biodegradability does not depend on moisture or temperature. The breakdown of PHA can even occur at 30 °C, which can be achieved under most home-composting conditions.

PLA is a non-toxic bioplastic that is safe for food contact. It can be used for transparent product packaging, bottles, containers, and more. However, PLA is unsuitable for packaging hot foods or beverages because it has a low-temperature resistance of around 43°C.

PLA is a popular choice for takeout food containers and fast-food outlets. For example, McDonald’s fast-food chain offers desserts and salads in PLA containers.

2. Biodegradable Packaging

Biodegradable packaging can be broken down by naturally occurring microorganisms. Every material will biodegrade, given enough time (even centuries). Certain biodegradable packagings degrade effectively in natural environments. In contrast, others require specific conditions not typically present outside industrial composting facilities.

Biodegradable packaging can be made with synthetic or natural resins. Petroleum-based products (a non-renewable resource) produce synthetic biodegradable packaging. A pivotal breakthrough in sustainable packaging lies in developing biodegradable packaging derived from renewable resources. Because renewable-based biodegradable packaging is plant-based, it attracts increased attention due to the significant benefits to the industry. Besides, it can reduce the total dependence on petroleum supply.

The most considered bio-based and eco-friendly plastic resources examined currently are Polylactic acid (PLA) and polyhydroxyalkanoates (PHAs). The starting material for PLA and PHA production is extracted from annually renewable plant materials. Because these biodegradable plastics may be restored to carbon dioxide and then photosynthesized by plants, the development of PLA and PHA can thus be considered carbon-neutral and null pollution processes.

REGEN™ packaging solutions are made using proprietary PHA from the forest industry’s renewable, untapped carbon sources. REGEN™’s PHA is designed for compostability, unlike PLA, which is less biodegradable. REGEN™ bioplastic is fully biodegradable in under 6 months at industrial composting facilities, complying with ASTM D6400 standards for products up to 3 mm thick.

This standard ensures compostable plastic breaks down through biological processes, resulting in water, carbon dioxide, inorganic substances, and biomass without leaving harmful residues. Through its 100% compostable solution, REGEN™ supports zero-waste initiatives and meets sustainability standards.

Biodegradable packaging plays an essential role in food packaging by enhancing the appeal and extending the shelf life of products. They are utilized in various packaging forms, such as net coverings, beverage bottles, and egg trays.

3. Edible Packaging

Edible packaging is gaining popularity as consumers become more concerned with health, food safety, nutrition, and waste reduction. This approach not only reduces carbon footprints but also improves food quality. Edible packaging can be consumed with food, allowing it to be eaten or discarded.

Historically, edible packaging has been used since the 12th century. It originated in China with wax-coated fruits and evolved with techniques like “Yuba” films in Japan and gelatin films in the 19th century. Although its development slowed in the 20th century due to plastic, growing consumer demand for sustainable packaging revives interest in edible options.

Edible films and coatings differ in their physical form and application. Films are solid sheets, while coatings are liquid applied to foods.

Edible films and coatings can be categorized into proteins (milk protein, collagen, gelatin, and zein films), polysaccharides (cellulose, chitosan, starch, and alginate films), lipids (natural waxes, acetylated monoglycerides, and resins), and composites (complex systems that consist of multiple components).

4. Recyclable and Reusable Packaging

Reduce, reuse, and recycle are tools to minimize the negative environmental impact of food packaging. Closed-loop systems that promote recycling and reusing materials reduce waste, minimize the use of virgin resources, and lower environmental impact.

Reusable packaging has historically been common, but there has been a shift towards single-use packaging, especially in countries without strict reuse legislation. Reusable packaging is a more efficient way to decrease packaging materials and energy use while minimizing production emissions. Reusable systems could potentially replace at least 20% of plastic packaging.

An increased emphasis on recycling supports a circular economy, reduces plastic waste, and minimizes environmental impact. Several major retailers, including Unilever, have committed to making 100% of plastic packaging reusable, recyclable, or compostable by 2030 (for rigid) and 2035 (for flexibles). Such initiatives showcase the industry’s recognition of its environmental responsibilities and the need to evolve with consumer expectations. They also drive cost savings by reducing material usage and waste disposal costs, thereby improving a retailer’s bottom line.

5. Smart Packaging Technologies

Smart packaging improves food safety, enhances shelf life, and provides better consumer information. Innovative packaging can be active or intelligent.

An active package modifies the condition of packaged foods, while an intelligent package performs intelligent functions, such as detecting, registering, locating, and communicating. Hence, smart packaging provides a complete packaging solution.

For instance, an active packaging film with insect-repellent properties incorporates star anise essential oil into a multilayer PET-based film. This film is practical in natural food systems, such as bread packaging, by preventing insect infestations.

Technologies such as RFID (Radio Frequency Identification) and QR codes are widely used to monitor the location and condition of products, such as temperature and humidity, throughout the distribution chain. This real-time monitoring enables the early identification of logistical issues, such as breaks in the cold chain, thereby preventing the compromise of food quality.

Benefits of Compostable Food Packaging

Compostable food packaging offers a sustainable alternative to traditional, often plastic, options. Utilizing materials derived from renewable sources like plants, these packages decompose naturally quickly, minimizing their environmental impact.

This shift towards compostable solutions presents a significant opportunity to reduce plastic waste, conserve resources, and mitigate the negative effects of conventional packaging on ecosystems.

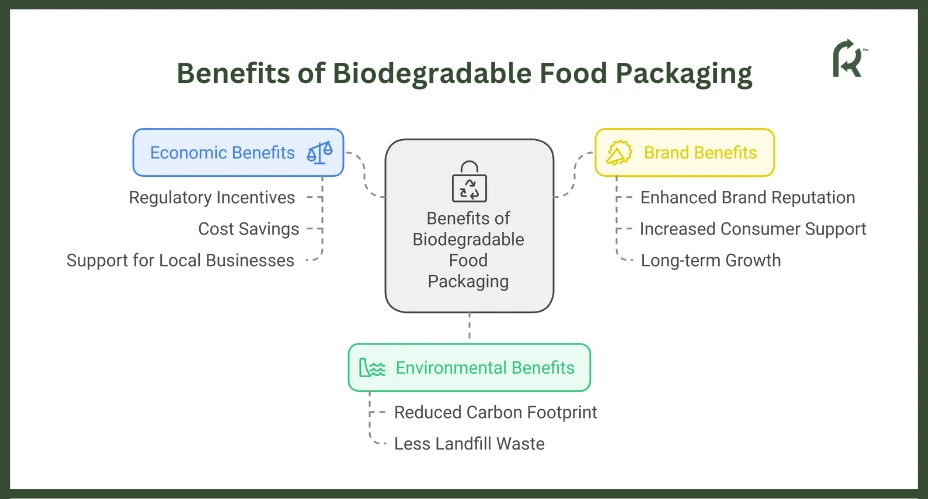

1. Environmental Benefits

Compostable food packaging is designed to be environmentally friendly throughout the life cycle, from production to disposal. These materials decompose more quickly than conventional plastics, reducing the carbon footprint, landfill waste, and environmental impact.

2. Economic Benefits

As governments worldwide impose stricter regulations on packaging waste and environmental impact, brands that adopt sustainable practices may receive incentives and tax breaks. Money-saving opportunities also arise from reducing the amount of waste created. Moreover, businesses focusing on sustainable packaging can support local businesses by buying locally produced products.

3. Brand Benefits

Sustainable packaging enhances brand reputation and aligns with corporate social responsibility initiatives, attracting consumers who prioritize sustainability. Customers are more inclined to support companies actively seeking to reduce environmental harm. Hence, this dedication increases brand loyalty and competitive advantage. Sustainable packaging ultimately promotes long-term growth and a sense of community among customers, making it more than just an ethical choice.

Challenges in Implementing Green Food Packaging

Companies that want to use green food packaging must deal with issues like high prices and a shortage of environmentally friendly materials and technology.

Another challenge is consumer perception, as many people may not believe green claims, which could result in the inappropriate disposal of eco-friendly products.

Regulations are more complex because different markets have different requirements, which leads to confusion. Businesses can improve labeling, educate customers, maximize packaging use, and work with stakeholders to find sustainable solutions to overcome these obstacles.

Key Takeaways

- The demand for sustainable packaging is rapidly increasing due to increased environmental awareness and regulatory pressure.

- Alternatives such as biodegradable, compostable, and edible packaging are emerging to meet consumer demands while reducing waste and carbon footprint.

- Eco-friendly products, such as REGEN™ bioplastics, are increasingly being used in food packaging, and mainstream companies are following this trend, making it one of the primary ways for brands to build relationships with their customers.

Frequently Asked Questions

Do Consumers Prefer Sustainable Food Packaging?

Support for businesses grows when they address customers’ environmental concerns. Using sustainable packaging meets the demand for eco-friendly, socially responsible products. Brands committed to sustainability demonstrate ethical practices, building customer trust.

Is Sustainable Food Packaging More Expensive?

High production costs hinder the adoption of biodegradable packaging, which is pricier than conventional options. Despite higher upfront costs, sustainable materials offer long-term savings alongside environmental benefits.

Is Recyclable Packaging Always Better for the Environment?

Recycled packaging is 85% more eco-friendly than manufactured plastic, as it does not end up in landfills. Recycling turns waste into resources, reducing raw material use, emissions, and energy consumption. However, contamination hinders recycling, making some materials unusable. Moreover, profit-driven companies frequently incinerate waste due to poor recycling systems and low profits. Biodegradable packaging offers a sustainable alternative but faces its own challenges.