The excessive consumption of fossil energy depleted petroleum resources and caused environmental pollution. Biomass, which is renewable and readily available, has been exploited to replace petroleum resources and design non-toxic, safe resin alternatives.

New resins with superior and unique qualities are created using molecular design and synthesis to take advantage of substitute products that have qualities comparable to petrochemical resin.

Resin alternatives like REGEN™ PHA offer eco-friendly, biodegradable, and non-toxic solutions that significantly reduce environmental impact. These bioplastics are designed to minimize reliance on petroleum-based plastics and enhance circular economy practices.

Some benefits include biodegradability, reduced carbon footprint, and safety for ecosystems, as they contain no harmful additives. Made from renewable feedstocks and exhibiting superior performance compared to PLA, REGEN™ PHA supports composting systems to create nutrient-rich soil.

Why Should You Seek Safe Alternatives to Petrochemical Resin?

The utilization of petrochemical resin negatively impacts the environment, leads to air pollution, and poses health risks because toxic chemicals are released.

Due to growing environmental concerns and reducing petroleum reserves, researchers have tried replacing conventional petroleum-based resins with sustainable and environmentally friendly biomass-derived resins. These biomasses include, but are not limited to, vegetable protein, carbohydrate, vegetable oil, lignin, and tannin.

Public concerns about the environment, climate change, and the depletion of fossil fuel resources drive the growing commercial interest in safe alternatives.

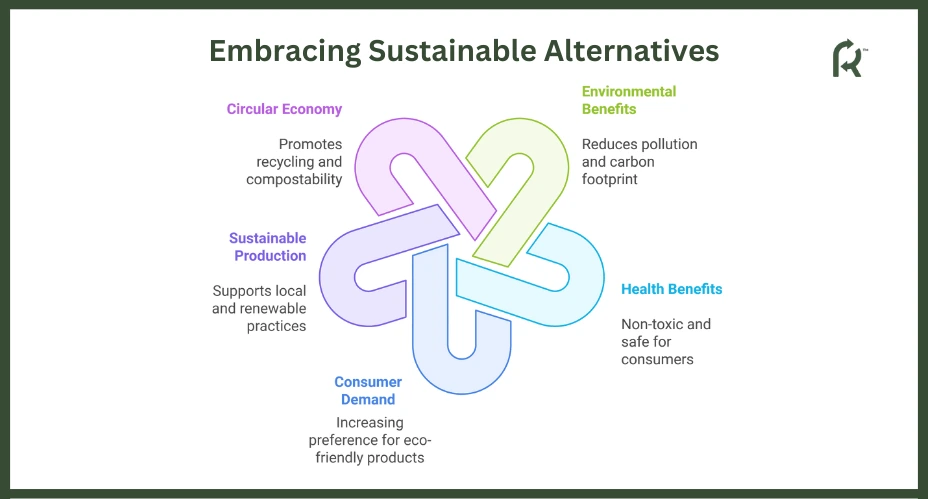

Customers are willing to pay more for products that meet environmental standards. Today, more than 62% of customers are willing to change their purchasing habits to reduce their environmental impact. Their rapid expansion demonstrates how social and environmental responsibility can be a key differentiator for products and brand identity.

Switching to bio-based, compostable alternatives like REGEN™ provides significant environmental and health benefits. These products reduce carbon footprints using renewable sources and meet strict compostability standards.

Additionally, they help eliminate microplastic pollution and support local, sustainable production practices. REGEN™ products are non-toxic, making them safe for food packaging and consumer goods applications.

Their versatility and adherence to quality standards enhance their appeal for various uses, contributing to a circular economy. By switching to REGEN™ bio-based, compostable, biocompatible alternatives, businesses and consumers can contribute to a cleaner planet, mitigate climate change, and embrace a safer, non-toxic future for all.

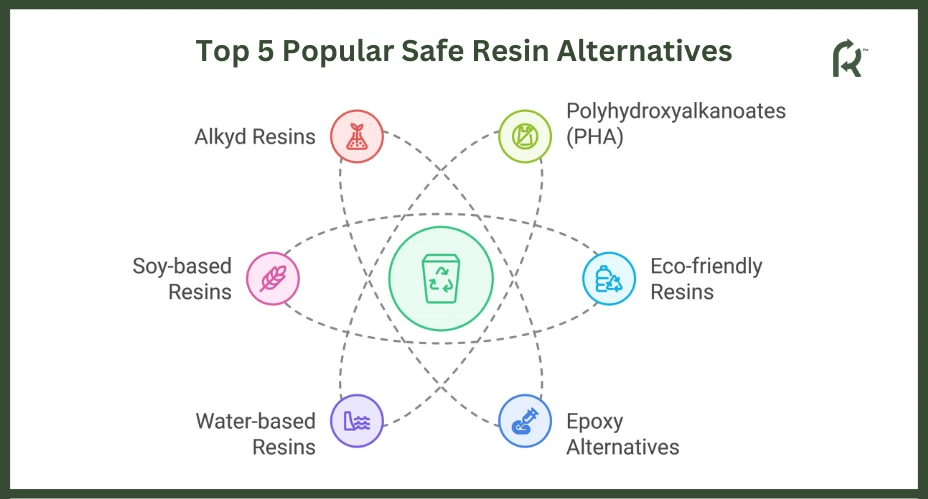

Top 6 Popular Safe Resin Alternatives

Safe resin alternatives are made from renewable resources like plant oils, starches, and natural fibers. They have gained popularity recently because they have a lower environmental impact and carbon footprint than traditional petroleum-based resins.

1. Polyhydroxyalkanoates (PHA)

In the quest for sustainable and environmentally friendly solutions to replace conventional plastics, polyhydroxyalkanoate (PHA) is emerging as the best-in-class alternative.

Using life cycle assessment (LCA) on PHA, researchers have evaluated its environmental performance regarding carbon footprint.

The authors concluded that PHA-based plastics laminated with either aluminum or aluminum oxides have a lower carbon footprint than PHA/PLA and conventional plastics.

The authors suggested that PHA-based plastics have the potential to be a sustainable alternative to conventional plastics, especially in the context of a circular economy. As a circular resource, PHA as an end product can be recycled and removes the need for virgin materials as an input.

PHA can replace petroleum-derived plastics since it has many attractive advantages, including being biobased and representing a circular product.

PHA decomposes into resources like water, CO2, and two inorganic chemicals. PHA has the potential to be used in different industries and sectors.

Producing PHA from sewage can reduce waste and carbon emissions. So, using PHA can mitigate the worldwide plastic problem we are facing now.

Hence, REGEN™ offers a sustainable alternative with its PHA designed to break down in composting facilities and natural environments. Made from renewable resources, REGEN™’s PHA reduces greenhouse emissions and addresses the environmental impact of fossil fuel-based polymers.

2. Eco-friendly Resins

Recent advances in biomaterials and biofabrication techniques have increased interest in biodegradable polymers like polylactic acid (PLA) or starch-based resins as sustainable alternatives to traditional resins, such as polypropylene.

PLA production is increasing for various industrial applications due to its competitive cost and eco-friendly environmental footprint. However, unlike REGEN™’s PHA, PLA is resource-intensive and requires agricultural land otherwise used for food production.

Moreover, PLA is less biodegradable than REGEN™’s PHA. REGEN™ PHA is compatible with conventional manufacturing equipment, offers competitive cycle times, and has excellent mechanical and physical properties comparable to traditional PLA resins.

3. Epoxy Alternatives

The development of epoxy resins mainly depends on non-renewable petroleum resources, which are toxic to human health. Among the bio-based resins, epoxy resins are currently the most developed.

These resins have significant advantages, such as low shrinkage, easy moldability, good adhesion, and high weather resistance, making them attractive for numerous applications in various sectors.

Currently, epoxy resins with a bio-based content of around 30% are available, with a considerably lower environmental impact. Fully bio-based resins are considered systems in which the epoxy precursor and hardener are from renewable sources.

The curing agents used for cross-linking epoxy resins are polyamines and carboxylic compounds. Therefore, to obtain a 100% bio-based system, one of the most attractive alternatives is to give vegetable oils the appropriate functionality to act as hardening agents.

Non-toxic, safe alternatives ideal for DIY projects and suitable for art and design include polymer clay, beeswax, water-based children’s paints in solid or liquid form, and wood glue. For instance, acrylic paints are also water-based but should be avoided (they can contain ammonia and formaldehyde).

4. Water-based Resins

Water-based resins are preferred over organic solvents whenever possible due to their superior environmental friendliness and enhanced safety features, including reduced fire, explosion, and worker physiological risks.

Water-based resins have a low VOC (volatile organic compounds) content compared to solvent-borne coatings. The most common uses for water-based resins are coatings and adhesives. However, there are still certain drawbacks.

Many polymer systems do not dissolve or disperse nicely in water but prefer organic solvents. Additionally, water-phase monomer polymerization to obtain waterborne polymers is impossible for many preformed polymers (including biopolymers), and organic solvents are frequently required as part of the overall process. Lastly, the evaporation temperature for water is often higher than its organic solvent counterparts.

5. Soy-based Resins

Due to their high soybean protein content, soybeans are the primary feedstock for preparing vegetable-protein-based resins. Soy protein isolate is a coproduct of the soybean process that contains more than 90% protein by weight.

Soy protein is the most produced edible plant protein, and the research on its adhesive properties dates back to the 1920s. Since then, soy-based adhesives have been commercialized in the plywood and automotive industries until synthetic formaldehyde-based adhesives emerged in the 1960s. Soy-based resins are environmentally friendly because they are both biodegradable and renewable.

6. Alkyd Resins

Alkyd resins are mainly biobased since they are polymers of monomers from renewable resources, such as vegetable oil. They were polymerized for the first time in the mid-1920s. They have been primarily used as coatings or binders in paints since the 1930s, owing to their numerous advantages over other resins, including good heat resistance, excellent gloss, and low cost.

In the 1950s, they were replaced by water-based coatings and synthetic polymers, primarily acrylic. Nonetheless, in the 1980s, environmental concerns prompted a renewed focus on alkyd resin research. Alkyd resins are typically diluted with organic solvents derived from petroleum resources. These organic solvents are classified as VOCs. They must be replaced, and new synthetic routes must be developed to create the most sustainable alkyd hybrids possible.

Which Resin Alternative Should You Choose?

Choosing the right resin alternative is essential for meeting project requirements and sustainability goals. REGEN™ stands out as a leader in biobased and compostable materials, validated by certifications and recognized for its versatility across multiple industries.

REGEN™ products are suitable for various applications, including art and jewelry making, construction, 3D printing, packaging, and DIY crafts. They offer advantages like a smooth finish, durability, and non-toxic properties that are safe for skin contact. In packaging, REGEN™ materials are fully compostable and biodegrade faster than conventional options.

Adopting sustainable practices that align with consumer preferences can help reduce operational costs while increasing market access by meeting eco-certification standards. Furthermore, businesses prioritizing sustainability see increased brand loyalty and attract investment from environmentally conscious funds.

How to Choose the Right Safe Resin Alternative?

When selecting a resin alternative that’s safer for your health, consider application needs such as durability, functionality, and environmental exposure.

- Evaluating sustainability credentials involves looking for biobased content and non-toxic formulations.

- Choose resins with minimal additives and confirm that certified compostable options leave no harmful residues.

- Certifications like BPI Compostable and ASTM standards help assess compliance with biodegradability and toxicity.

- Additionally, consider the environmental impact by opting for resins with a low carbon footprint that fits within a circular economy.

- Lastly, align your choice with brand goals while evaluating cost and scalability, as bioplastics are becoming increasingly accessible.

REGEN™ products are flexible and ductible, representing a versatile solution for industries seeking sustainable materials without compromising performance or safety. This makes them versatile options with many applications, including cosmetic packaging and 3D printing. REGEN™ aligns with industry-specific needs while addressing environmental concerns. This adaptability positions REGEN™ as a critical player in transitioning to a more sustainable future.

Top Brands Offering Safe Resin Alternatives

REGEN™ has emerged as a pioneer in developing biobased and compostable materials. The company’s commitment to sustainability, product performance, and transparency has established REGEN™ as a trusted name for industries transitioning toward eco-friendly solutions.

REGEN™ PHA-based resins outperform many competitors in durability and versatility. They are less brittle than PLA and designed to endure mechanical stresses, making them suitable for packaging, 3D printing, and consumer goods.

REGEN™ products meet strict compostability certifications (BPI, TUV, CMA) and can fully biodegrade in under six months at industrial composting facilities, particularly for products up to 3 mm thick. Committed to a circular economy, REGEN™ utilizes renewable resources to minimize waste and reduce greenhouse gas emissions, addressing environmental issues linked to traditional plastics.

Key Takeaways

- Safe resin alternatives are sourced from renewable materials and possess properties such as biodegradability, renewability, cost-effectiveness, abundance in nature, and non-toxicity.

- Nowadays, there are numerous biodegradable options available, free from harmful chemicals, suitable for indoor use, and made from natural materials.

- Selecting the appropriate resin alternative is crucial for fulfilling project requirements and achieving sustainability goals.

- REGEN™ products are biobased and compostable, suitable for various applications, offering durability and safety while promoting sustainability and enhancing brand loyalty in businesses.

Frequently Asked Questions

Are Safe Resin Alternatives as Durable as Traditional Resins?

REGEN™ PHA, a safe resin alternative, is less brittle than PLA and offers superior barrier properties. It is stronger, withstanding higher pressure and stress without breaking or deforming. Additionally, PHA is more durable and resistant to harsh conditions.

Do Safe Resin Alternatives Cost More Than Regular Resins?

Safe resin alternatives cost more because of higher raw material expenses, advanced technology, and specialized facilities. Prices will drop as technology advances, demand increases, and global policies support safe resins. Despite the initial expense, their long-term environmental and health benefits make them a worthwhile investment.

Are All Eco-friendly Resins Non-toxic?

Not all eco-friendly resins are non-toxic. Genuine options like PHA and PLA are biobased and biodegradable, while PHA is also compostable, leaving no toxic residues. Some biodegradable plastics, however, may contain harmful additives or be of petrochemical origin. Eco-friendly resins may release minor substances during degradation, raising concerns for food or medical uses. Products like REGEN™ PHA are suited for technical applications, offering environmental benefits without leaving harmful residues.