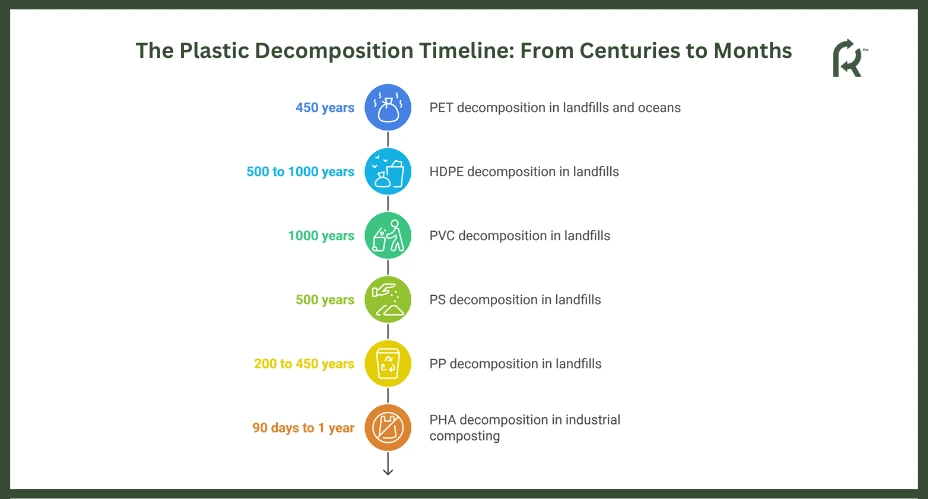

Plastic breakdown varies by type, composition, and environmental conditions. Conventional plastics like polyethylene and polystyrene can persist for centuries, undergoing photodegradation but often breaking into microplastics rather than entirely decaying. At the same time, bioplastics such as PLA and PHA decompose more quickly, especially PHA, under industrial composting conditions.

Certified compostable plastics, meeting the rigorous standards set by the American Society for Testing and Materials (ASTM), break down within 90 days in controlled environments without leaving harmful toxins.

These standards ensure that the plastics are genuinely compostable and environmentally friendly. Because they break down more quickly and have less of an impact on the environment, biodegradable solutions like REGEN™ PHA are essential.

Sustainable businesses enable consumers to make environmentally friendly decisions. By promoting these materials, lowering the usage of petroleum-based plastics, and minimizing waste, they highlight the power of consumer demand and the role of businesses in reducing plastic waste.

How Long Does It Take for Plastic to Dissolve?

Traditional plastics tend to fracture into microplastics, a process that can take decades. This prolonged decomposition underscores the urgent need for sustainable substitutes. This section reviews these variations and stresses the immediate need for sustainable alternatives to mitigate the detrimental effects of plastic waste on the ecosystem.

1. PET (Polyethylene Terephthalate)

Polyethylene terephthalate (PET), often found in bottles and grocery bags, is a strong thermoplastic that can be recycled. Because of its strong ester linkages, it is highly resistant to natural deterioration and can withstand 450 years or more in landfills and the ocean.

This prolonged decomposition adds to and promotes the amount of plastic garbage and seriously damages the ecosystem. In contrast, biodegradable alternatives like polyhydroxyalkanoates (PHA) break down in as little as 90 days under industrial composting, leaving no toxic residues. PET’s resilience highlights the need for sustainable solutions, and innovations like REGEN™ bioplastics help reduce waste, support circular economy principles, and promote a healthier planet.

2. HDPE (High-Density Polyethylene)

High-density polyethylene (HDPE), used in items like milk jugs and detergent bottles, is a durable plastic resistant to UV radiation and moisture. However, its longevity means it can take 500 to 1000 years to decompose in landfills, contributing to plastic waste and microplastic pollution. This property underlines the urgent need for more environmentally friendly alternatives for waste reduction and environmental safety.

3. PVC (Polyvinyl Chloride)

Polyvinyl chloride (PVC) is a durable plastic that is also resistant to environmental factors. However, it can be resistant to environmental factors. It takes up to 1000 years to decompose in landfills. Unlike biodegradable materials like PHA, which decompose in as little as 90 days when composted, PVC produces toxic chemicals like vinyl chloride and dioxins that are extremely dangerous for the environment and human health.

4. LDPE (Low-Density Polyethylene)

Low-density polyethylene (LDPE), used in plastic bags and packaging films, is a flexible, durable plastic that, due to its stable chemical structure and lifespan, can take more than 500 years to decompose in landfills and oceans.

This persistence contributes to litter and microplastic pollution. The significant difference in degradation times between LDPE and bioplastics highlights its unsustainability and promotes the shift to biodegradable materials to reduce waste and improve environmental safety.

5. PP (Polypropylene)

Polypropylene (PP) is known for its durability, moisture, heat, and chemical resistance. These properties make it highly persistent in the environment, and decomposing in landfills takes 200 to 450 years.

Its hydrocarbon-based structure resists natural degradation, unlike biodegradable alternatives like PHA, which break down in 3-6 months in industrial composting.

6. PS (Polystyrene)

Polystyrene (PS) is commonly found in food containers and packaging. It is highly resistant to environmental influences and takes about 500 years to break down into microplastics in landfills.

This adds to pollution, especially in marine habitats. On the other hand, biodegradable substitutes such as polyhydroxyalkanoates (PHA) are ideal since they don’t leave any harmful residues and promote sustainability. Switching to these materials is essential to lessening the long-term environmental effects of single-use plastics.

7. PHA (Polyhydroxyalkanoates)

Polyhydroxyalkanoates (PHA) are bioplastics known for their rapid decomposition and minimal environmental impact. Unlike conventional plastics like PET, which persist for over 450 years, PHA breaks down in industrial composting within months to a year.

Due to its structure, produced by microorganisms, PHA is resistant to UV and moisture during use but remains biodegradable after disposal, outperforming alternatives like PLA. Made from renewable resources, PHA products, like those from REGEN™, support sustainability and offer a promising solution to replace fossil fuel-based plastics, reducing long-term waste. The potential of biodegradable materials like PHA gives hope for a future with less plastic pollution.

Why Does Plastic Take So Long to Decompose?

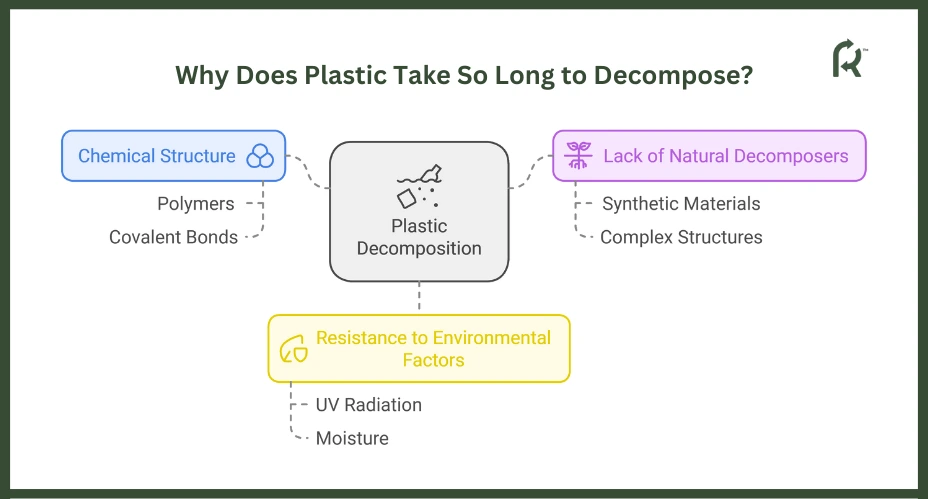

Plastic decomposes exceptionally long due to its durable chemical structure, which is designed to resist environmental degradation.

Unlike organic materials, plastics lack the natural enzymes or microorganisms required to break down their synthetic polymers efficiently, which has led to their persistence in ecosystems for centuries.

1. Chemical Structure of Plastics

Plastics have a chemical structure consisting of long chains of molecules called polymers, which form through polymerization. Strong covalent bonds hold these polymers together, making them highly stable and difficult to break.

This durability in the chemical bonds gives plastics their resistance to decomposition. Unlike natural substances with weaker molecular structures, the long, tightly bonded chains make it hard for microorganisms to break down the material. As a result, plastics can persist in the environment for extended periods, contributing to long-term pollution.

2. Lack of Natural Decomposers

Plastics lack natural decomposers because they are synthetic materials with complex chemical structures that are not easily broken down by the organisms typically involved in decomposition, such as bacteria, fungi, or insects.

Unlike organic materials like food, wood, or plant matter, which are quickly broken down by natural decomposers, plastics have strong molecular bonds resistant to enzymatic activity.

As a result, few, if any, microorganisms are capable of efficiently breaking down plastics. The absence of natural decomposers leads to plastics accumulating in the environment, often persisting for hundreds or even thousands of years.

3. Resistance to Environmental Factors

Due to their stable chemical composition and strong molecular bonds, plastics are highly resistant to environmental factors like sunlight, moisture, and microbes.

UV radiation from sunlight can degrade many materials, but plastics are designed to resist this process when stabilized with additives.

Articles and studies show that moisture has little impact on plastics, as they don’t absorb water quickly, preventing degradation. This resistance contributes to plastics’ endurance in the environment, with items like plastic rings enduring for long periods without significant decay, consuming energy in the process.

How Brands Can Reduce Plastic Decomposition Time

Brands can reduce plastic decomposition time by adopting biodegradable alternatives, which break down faster than traditional plastics and lower their environmental footprint. Materials like PLA (polylactic acid) and PHA (polyhydroxyalkanoates) degrade through microbial activity, speeding up biodegradation and reducing long-term pollution.

For instance, Coca-Cola’s “PlantBottle,” made from up to 30% plant-based compounds, and Nestlé’s biodegradable water bottles have helped reduce plastic use and carbon footprints. Several studies show that these materials, including biodegradable straws, coffee cups, and coffee pods, are compostable, turning into organic matter without harming ecosystems.

Companies like PepsiCo and Unilever also invest in cutting-edge recycling technology, which enhances waste management and reduces greenhouse gas emissions. Biodegradable plastics outperform traditional plastics, demonstrating that sustainability does not compromise quality.

By switching to biodegradable materials, encouraging recycling, and promoting a circular economy, brands may drastically cut their carbon footprint and help combat climate change.

Key Takeaways

The need for faster-decomposing materials is becoming increasingly urgent as the environmental impact of plastic waste grows. Here are key reasons why transitioning to sustainable plastics is essential:

- Biodegradable alternatives reduce waste by breaking down faster than traditional plastics, minimizing long-term environmental pollution.

- Sustainable plastics support circular economies by promoting compostability and reducing reliance on non-renewable resources.

- Faster decomposition protects ecosystems by limiting plastic accumulation in landfills and natural habitats.

- Transitioning to eco-friendly materials enhances brand sustainability, aligning with consumer demand for environmentally responsible products.

Frequently Asked Questions

What is the Fastest Decomposing Plastic?

The fastest decomposing plastics are biodegradable types like PLA and PHA. PLA decomposes within months in industrial composting, while PHA breaks down in marine and soil environments. Both rely on microbial activity, offering reduced environmental impact compared to conventional plastics, which can take centuries to degrade.

Is There a Way to Speed Up Plastic Decomposition?

Industrial composting accelerates plastic decomposition by accelerating the breakdown of biodegradable plastics like PLA and PHA with controlled heat, moisture, and microbes. Enzymes and bacteria are also being studied to efficiently degrade plastics like PET, though these solutions are not yet widely available.

Can Recycling Reduce the Decompose Time of Plastics?

Recycling does not reduce the decomposition time of plastics, as it does not alter their chemical structure. However, it helps reduce waste and environmental impact. Companies like Unilever and Nestlé are adopting biodegradable plastics for faster decomposition and sustainability, complemented by recycling programs to lower greenhouse gas emissions.

Unilever’s “Love Beauty and Planet” line uses 100% recycled plastic bottles, while Nestlé aims for all packaging to be recyclable or reusable by 2025. These efforts improve sustainability and brand reputation, with recycling programs complementing the transition by reducing greenhouse gas emissions.