In the world of bioplastics, Polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are leading the charge away from the traditional in sustainable packaging.

With PLAs, you get a more cost-effective bioplastic while making sacrifices in biodegradability and the energy costs of producing the plastic. PHA is a little more expensive. But it makes up for that with a less resource-intensive manufacturing process and faster biodegradability.

Despite these differences, both are biodegradable, and both offer an energy-conscious alternative to traditional plastics.

In this PLA vs. PHA guide, we’ll examine two bioplastics side-by-side, comparing their characteristics, costs, and other key factors to help you decide which one to work with.

What Are Bioplastics?

Unlike regular plastic materials made from petroleum or other fossil fuel-based sources, bioplastics are materials made from biodegradable and renewable sources. The majority of bioplastics are also completely compostable.

Here are some of their biggest benefits:

- Biodegradable: Bioplastics decompose in a matter of months. For some, this requires special industrial facilities, but others will break down in landfills or water in next to no time, making them much kinder for the environment.

- Low Carbon Footprint: Bioplastic production has a tiny carbon footprint compared to conventional plastics. Project Drawdown says that switching to bioplastics will allow for a reduction of between 1.33 and 2.48 gigatons of CO2 equivalent between now and 2050.

- Non-Toxic: You won’t find harmful or toxic additives and ingredients mixed in with bioplastics. They’re made of safe, natural components and will break down to release nothing but carbon dioxide, water, and other safe, organic elements.

- Useful: Many bioplastics are strong, malleable, and versatile, making them well-suited to all sorts of applications. They’re used in packaging, medical products, toys, fashion items, and consumer goods galore.

An Overview of Bioplastics: PLA vs. PHA

There are two rising stars of the bioplastic world: PLA and PHA. Both of these biodegradable polymers have proven themselves popular and eco-friendly of late, emerging as ideal green alternatives to petroleum plastics, perfect for packaging, storage containers, plastic bags, bottles, and more. Let’s learn a little more about them and see how PLA and PHA compare.

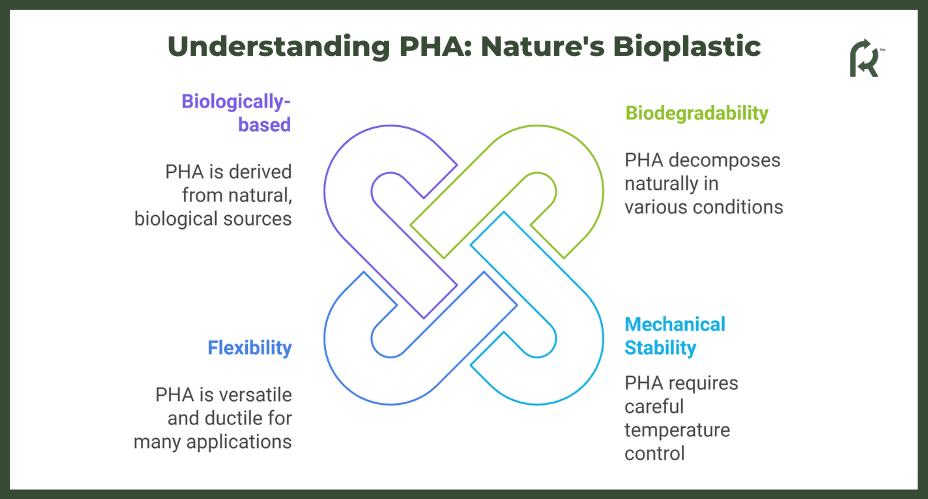

What Is PHA?

PHAs stand for polyhydroxyalkanoates. These are a group of biopolymers produced in the natural world by microscopic life forms like bacteria. PHA mimics nature’s processes to create a plastic capable of biodegrading. It doesn’t involve any kind of synthetic materials or chemicals, and scientists can cultivate PHAs in controlled laboratory settings, creating a vast supply of these materials.

Learn more about the sustainable production and unique properties of PHA plastics, a biodegradable material crafted by nature itself through microbial processes.

Some of the key properties of PHA include:

- Biodegradability: PHA is intrinsically biodegradable in almost all conditions. Its extraordinary capability to decompose naturally makes it one of the greenest bioplastics.

- Mechanical Stability: PHA doesn’t have the highest thermal stability. Careful temperature controls are necessary during application.

- Flexibility: PHA bioplastics are flexible and ductile. This makes them versatile options with a broad array of applications in packaging, such as food packaging coatings, bottles, and films. PHA is also used in the biomedical and textiles sectors, with the former seeing PHA use in implants, drug delivery devices, and implants.

- Biologically-based: PHAs derive from biological, natural sources, so they’re friendly to the environment.

What Is PLA?

PLA stands for polylactic acid. This natural bioplastic comes from plants like corn and sugarcane. Fermentation of these natural plant sugars leads to the production of lactic acid, which forms the building blocks of PLA. This plant-based plastic offers different properties than PHA but still has plenty of its own advantages.

If you’re curious about how polylactic acid is transforming packaging, check out our in-depth guide on the benefits and applications of PLA plastics, a versatile and eco-friendly alternative to petroleum-based materials.

Here’s what sets PLA apart as a premium packaging bioplastic:

- Biodegradable: PLA is biodegradable in certain settings. PHA breaks down better (more on that later) but PLA still has the ability to decompose into safe and natural components.

- Transparent: PLA has a level of transparency that few other bioplastics can match. It’s similar in style to cellophane, which makes it an appealing choice for visual or see-through packaging.

- Antibacterial: PLA has natural antibacterial properties. Antibacterial agents, like certain metals, enhance these properties and unlock applications in food and healthcare.

- Food-Safe: PLA is one of the few bioplastics found to be Generally Recognized As Safe (GRAS) under room conditions and available for the food packaging industry.

PLA vs. PHA: Which Is Better?

That’s the basics of PHA and PLA. Let’s see how the two measure up in a detailed PLA vs. PHA comparison.

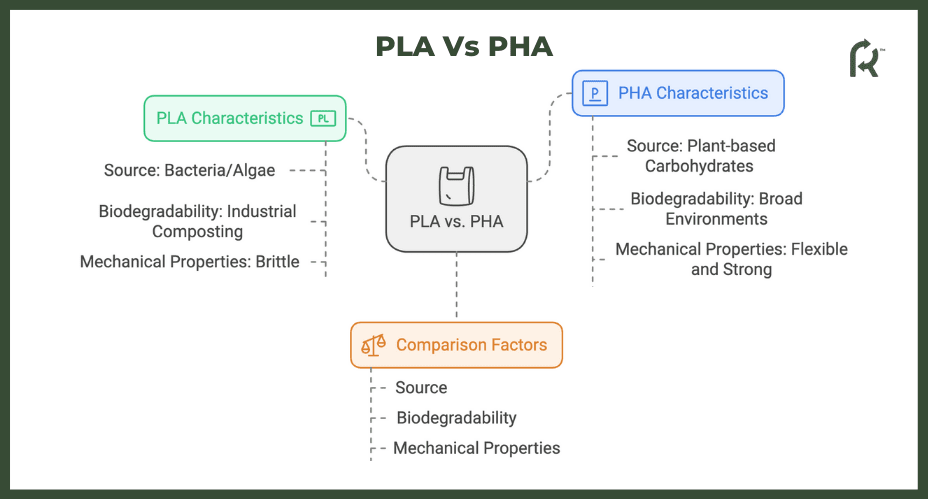

Source

Both PHA and PLA are bioplastics made from natural biomass. But the sources used to make each one are different.

With PHA, bacteria or algae do most of the work in producing the plastic material, provided they’re placed in the right conditions. Natural sugars and lipids (like plant oils) can both initialize and accelerate this process. It’s one of the most sustainable bioplastic production techniques currently in use.

For PLA, plant-based carbohydrates like corn starch or sugarcane are critical ingredients during the production process. This is still a natural process but is less renewable than PHA production. Growing the necessary crops at an appropriate scale for PLA production requires large amounts of agricultural land, along with vital resources like water and electricity.

Biodegradability

Both PLA and PHA are biodegradable, giving them an edge over other bioplastics. However, they biodegrade in different ways.

PHA has better biodegradability than PLA. It can break down organically and naturally in more environments and situations, whether in the soil, in water, or elsewhere. A piece of PHA packaging discarded in the wilderness will likely decompose there, making PHA disposal simple.

PLA demands more specific and controlled surroundings and circumstances to compost. It’ll only break down well in industrial settings, like composting facilities. PLA does decompose “in the wild,” but the process is slower than for PHA.

Visit our detailed analysis for a closer look at how PLA biodegradability works and the settings required for it to decompose. All REGEN™ bioplastics biodegrade in less than six months in accordance with the ASTM D6400 specification – discover the environment-saving power of REGEN™ today.

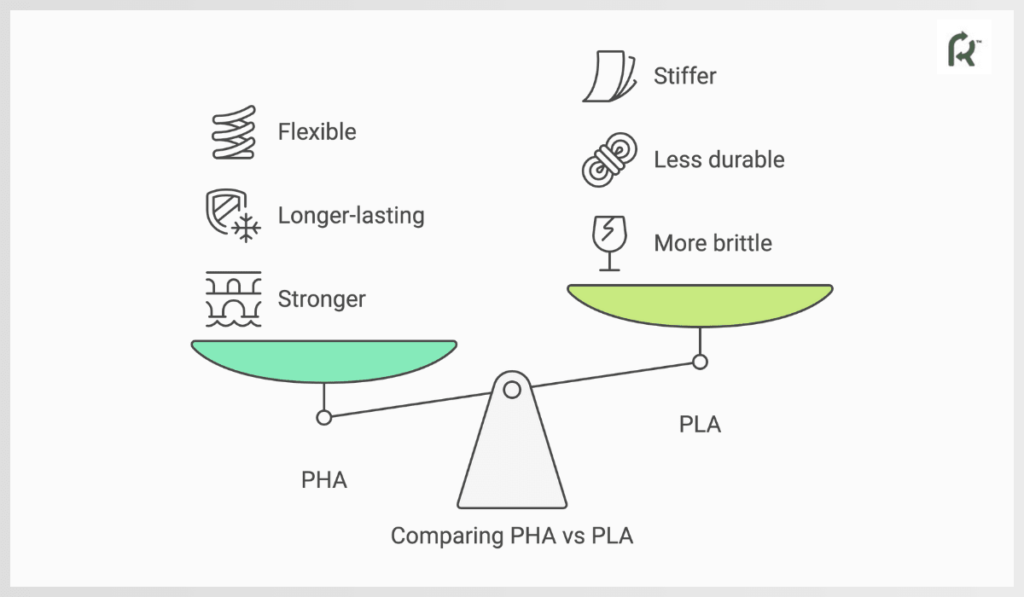

Mechanical Properties

Strength and flexibility inform your choice between PLA and PHA. Comparing both reveals that PHA has an edge in both departments. PHA is less brittle than PLA and provides better barrier properties. It tends to be stronger, coping with higher levels of pressure and stress before breaking apart or losing its shape. It’s more durable and resistant to harsh conditions, too.

PLA is still a strong plastic, but it is more brittle than PLA. It is less suitable for high-temperature applications or harsher conditions, and it lacks the range of flexibilities exhibited by different PHAs. However, it’s worth noting that the exact characteristics of each PHA or PLA depend on their production methods.

| PHA | PLA | |

| Strength | Stronger | More brittle |

| Durability | The longer-lasting option | Less durable |

| Flexibility | Flexible | Stiffer |

Production

The manufacturing processes for PLA and PHA differ despite both coming from natural sources.

PHA is the result of microbial production. Tiny organisms like bacteria and algae receive some sort of carbon source, like sugar or lipid, and ferment in controlled conditions. They then produce PHA as a natural byproduct of their metabolism. Extraction of the PHA for industrial or commercial use follows.

PLA is the result of plant-based extraction. The process begins with the growing and harvesting of a plant source, such as sugarcane. Sugars are then extracted from the plant-based carbohydrates before fermenting to give off lactic acid. That acid is then bonded into polylactic acid (PLA).

Between the two, PHA’s process demands milder conditions (lower temperatures) and fewer resources.

Sustainability Factor

The emergence and rising popularity of bioplastics are due to their sustainability. But which is more sustainable, PHA or PLA?

There are arguments for both bioplastics. The consensus is that PHA is more sustainable. It has a smaller carbon footprint and superior biodegradability, with less impact on the environment. At the same time, even though PHA is less energy-intensive than other bioplastics, as it doesn’t require any catalyst. It’s not a 100% green material because production still needs an energy source.

This could all change as technologies advance to enable new methods of producing bioplastics. A new method of creating PLA that is even more efficient than PHAs may rise in the future.

Cost

Of course, cost is always a factor when it comes to selecting materials to work with.

This is where the PLA has the advantage. It’s cheaper to make on the whole, with efficient, established, and affordable production processes, along with widely available and inexpensive raw materials like corn starch.

PHA costs more than PLA and presents a range of challenges in large-scale production. However, as the bioplastics industry evolves and improves, PHA production could become cheaper, easier, more efficient, and more eco-friendly.

How to Make the Right Choice for Your Brand

We’ve seen how PLA vs. PHA compare. But you still might not be sure which option is right for your specific packaging needs and objectives. Here’s some expert advice to guide you in the right direction.

Assess Your Packaging Needs

Before selecting any material to work with, it’s important to assess your own situation and identify your specific goals. Don’t follow trends or pick materials based on their reputation. Find the one that’s right for you and suits your business needs.

Suppose you have a tight budget but want to invest in eco-friendly bioplastics to appeal to your customers and reduce your carbon footprint. In that case, PLA would be an optimal solution, offering cheaper prices for mass production while still being a green choice.

Perhaps budget isn’t a big issue, and you want to create packaging that people can toss in their compost heaps to decompose alongside other waste. The obvious option becomes PHA due to its superior biodegradability.

Here are some questions that might nudge you toward one bioplastic over another:

- What is our packaging budget?

- How sustainable/green do we want our packaging to be?

- What are the use cases and disposal methods for our packaging?

- What conditions will the packaging encounter?

Align the Packaging Solution to Your Brand Values

It’s also worth considering your brand’s values and sustainability ethos to make the right bioplastic selection.

Those 100% committed to going as green as possible, no matter the cost, will lean towards the more sustainable option – PHA. Other brands may need to balance eco-friendliness with their budgetary and logistic constraints, in which case PLA may be more suitable.

PLA/PHA vs. ABS: How Do They Compare?

Let’s compare bio-based plastics like PLA and PHA against petroleum-based plastics like ABS (acrylonitrile butadiene styrene). ABS is one of the most-used commercial plastics, featured in everything from toys like LEGOs to medical devices, sports equipment, and kitchen appliances. It’s popular for 3D printing, too.

- Environmental Impact: From an ecological perspective, ABS is bad news. It’s made from petroleum, a fossil fuel, and isn’t compostable or biodegradable like PLA or PHA.

- Usability: In most performance metrics—strength, durability, flexibility—ABS is superior. It’s a strong plastic with usage potential in many industries.

- Consumer Perception: As general awareness around the environmental impact of plastics grows, consumers have created a more favorable view of bioplastics than ABS. A 2019 study shows that 68% of people prefer their plastic items to be biodegradable – bad news for ABS plastics that suck up Earth’s resources.

Try Innovative Bioplastics by REGEN™

Bioplastics like PHA and PLA are the future because they counter the effects traditional plastics have on the planet. REGEN™ is pushing the boundaries of what a bioplastic can be. Our unique, innovative bioplastic uses a smart PHA blend with a mix of ingredients to bolster its physical properties. Our formula is top secret. However, we can tell you that REGEN™ PHA is a natural biopolymer made using bacteria and breaks down naturally within a few weeks. It’s as strong and practical as classic types of plastics, without the negative environmental impact, making it the perfect choice for your packaging needs.

Here’s what sets REGEN™ bioplastic apart:

- An upgrade on traditional PHAs

- Completely biodegradable within six months

- Non-toxic and compostable

- Strong and practical for myriad applications

With REGEN™, you get a material that’s as practical as plastic without the harmful impact traditional plastic has. We outperform PLAs and standard PHAs in technical applications, with our PHA 4.0 offering enhanced compostability. Choose REGEN™ for a sustainable packaging solution that aligns with your sustainability needs. Our biobased-certified PHA offers comparable performance to oil-based resins with none of the fossil fuel drawbacks.

Key Takeaways

-

- Traditional plastics are polluting the planet and destroying the ecosystem.

- Sustainable bioplastics like PLA and PHA provide a greener, kinder alternative.

- PHA is superior in many aspects but costs more to make.

- Brands should take care when selecting plastics for packaging and other needs.

- REGEN™ offers an innovative take on PHA for perfect bioplastic packaging solutions.

Frequently Asked Questions

Is PHA Stronger Than PLA?

Yes, on average, PHAs are stronger than PLAs. PHA has mechanical properties different from PLA, which help it withstand harsh conditions.

Is PLA Bioplastic Safe to Use?

Yes, it’s considered a safe material due to its natural origins, which is why PLA is often used in the medical and food sectors.

What Is the Lifespan of PLA Plastic?

PLA plastics are capable of lasting over 10 years, but it depends on how and where they’re used and stored. They can break down or deform under duress or high temperatures.