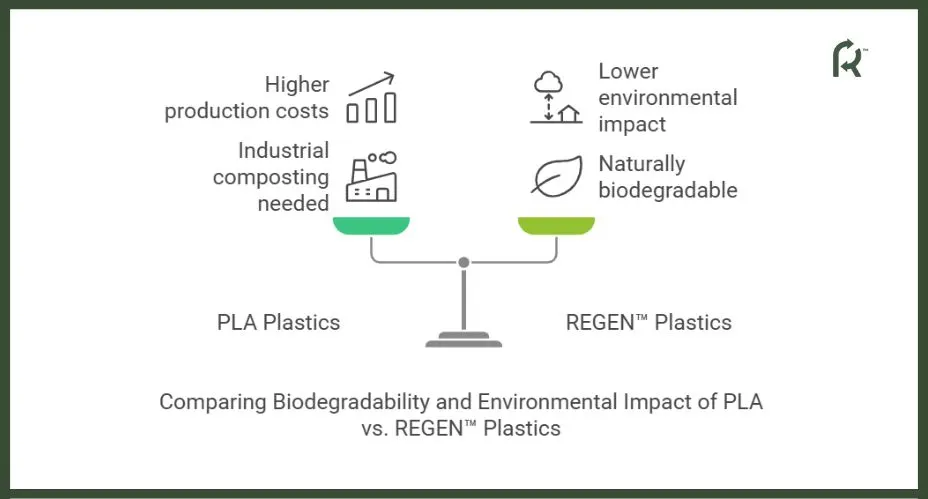

PLA plastics offer you a chance to create more eco-friendly packaging because they’re derived from natural materials. That doesn’t mean PLAs are the best bioplastics. It’s resource-intensive and requires agricultural land that is otherwise used for food production. Alternatives, such REGEN™, are also fully biodegradable without requiring the industrial conditions needed to biodegrade PLAs.

Non-toxic, bio-based, and biodegradable (to a certain extent), PLA plastics still bring plenty to the table. They’re ideal for a vast, varied array of applications and have proven invaluable in sustainable, low-impact packaging. They’re used for containers, linings, and wraps around the globe.

However, PLA plastics are not perfect, nor are they the only alternative to classic, petroleum, or resin-based plastic. There are plenty of other bioplastics and sustainable choices out there, including PHAs and starch-based plastics. This guide will take a look at a few while breaking down the pros and cons of PLA.

An Overview of PLA and the Need for Broader Solutions

PLA stands for polylactic acid, and PLA plastics are currently among the most popular bioplastics. They’re made from a base of plant materials. Corn, sugarcane, and sugar beets are most often used as the basis for PLA production. After they’re grown and cultivated, the plants go through several processes, like hydrolysis and fermentation, to create lactic acids.

To understand the broader category of eco-friendly materials and their various uses, take a look at our detailed guide on bioplastics and how they can replace traditional plastics.

The result is lactic acids – the building blocks of PLA. Using a process called polymerization, manufacturers link these acids together to create biodegradable PLA.

Blending this PLA with other polymers lends the new plastic differing properties for varying applications. Their strength, durability, and flexibility all vary depending on how they’re made and the application of different additives, such as plasticizers, antioxidants, and anti-hydrolysis agents.

Since PLA plastics come from renewable, plant-based materials, they are a great alternative to traditional and harmful petroleum-based plastics. They have other benefits, too. They present low toxicity and provide good clarity and gloss.

Thanks to this, they have many applications. Food packaging and 3D printing fall under the PLA remit, as do medical applications like sutures and drug delivery systems.

However, PLA plastics do have issues (more on that below). As such, there’s a widespread consensus to look beyond them and seek out alternative sustainable packaging materials.

- Imperfect Properties: For all its relative strength, PLA isn’t perfect or universally usable. PLA plastics are brittle at low temperatures, for example, and are susceptible to hydrolytic degradation. They’re not as strong or hard-wearing as other bioplastics or classic plastics.

- Resource Dependent: The PLA production method is quite resource-intensive. Growing the necessary crops requires a large amount of agricultural land, so companies may prefer options that require less energy for production.

- Scalability: PLA is 100% renewable, but since it demands so many resources and has a complex, multi-stage production process, it’s not the most scalable of bioplastics. It requires a certain level of infrastructure and investment to produce in vast quantities.

To learn more about whether PLA is truly biodegradable and the conditions required for it to break down, check out our comprehensive article on is PLA biodegradable.

Limitations of PLA Plastics

As touched on above, PLA plastics are not without their flaws. Some of the limitations of PLAs include:

- Temperature Sensitivity: PLAs don’t have a high melting point or cope with warm or hot conditions very well. Heat makes them break down and lose their shape. Many of them will even begin to decompose when temperatures reach a certain point.

- Limited Durability: Certain varieties of PLAs have high stiffness and strength, but they’re not always the longest-lasting bioplastics. They’ll wear out fast, especially if they’re used outside or exposed to light, moisture, and changing temperatures.

- Not 100% Sustainable: They may be renewable and recyclable, but PLA plastics aren’t entirely sustainable. They can only decompose under industrial composting conditions that include temperatures above 140 degrees Fahrenheit and relative humidity of 90%, so they aren’t naturally biodegradable, and it takes time and energy to break them down. This contrasts with REGEN™, which biodegrades naturally with no special conditions needed.

Market Challenges

PLA plastics pose challenges from an economic perspective. They’re tricky to produce in vast quantities since they use the same resources as food.

They’re often more expensive to make than conventional plastics, and their production costs are proportional to the costs of crops – if the cost of corn rises, so too does the cost to produce PLAs.

Not only that but from a supply chain standpoint, PLA production is always reliant on crop availability. Land, soil, and weather conditions all have to be right to grow crops in sufficient quantities (and of the right quality), and there are geographic limitations to consider, too. This, coupled with PLA’s inherent performance restrictions, limits its potential for widespread use.

Environmental Impact

PLA is renewable and more environmentally friendly in many aspects than conventional plastics. But that’s not to say it has zero ecological impact. From the outset of their lifecycle through to their eventual disposal or decomposition, PLA plastics have numerous impacts on the natural world.

Without growing crops, these plastics can’t exist. The process takes up land and requires water, nutrients, and energy. Energy and resources are then spent to harvest the crops, extract their sugars, ferment those sugars, and polymerize the resulting lactic acids into polylactic acid. Add to this the industrial-level conditions needed for PLA decomposition and you have clear resource requirements that impact the environment.

Here’s how PLAs compare to other plastics on the eco-impact front:

- Carbon Footprint: Compared to conventional plastics, PLAs have a much lower carbon footprint. They don’t require petroleum or any other fossil fuels, nor do they have such energy and resource-intensive production. However, they’re not as eco-friendly as PHAs, such as those produced by REGEN™, which are makeable using wood residue and similar plant matter that are offshoots of existing farming processes.

- Pollution: PLAs usually don’t cause as much pollution or ecological damage as conventional plastics. Their sustainable value decreases if they’re not disposed of correctly. If they’re tossed in landfills or bodies of water, they’ll last years before breaking down, just like traditional plastics.

What Are the Best Bioplastic Alternatives?

PLA plastics have their pros, but also their downsides. They are biodegradable—under certain conditions—and strong and flexible, too, but their mechanical properties – like temperature resistance – can vary from one material to another. Here are some of the leading alternatives.

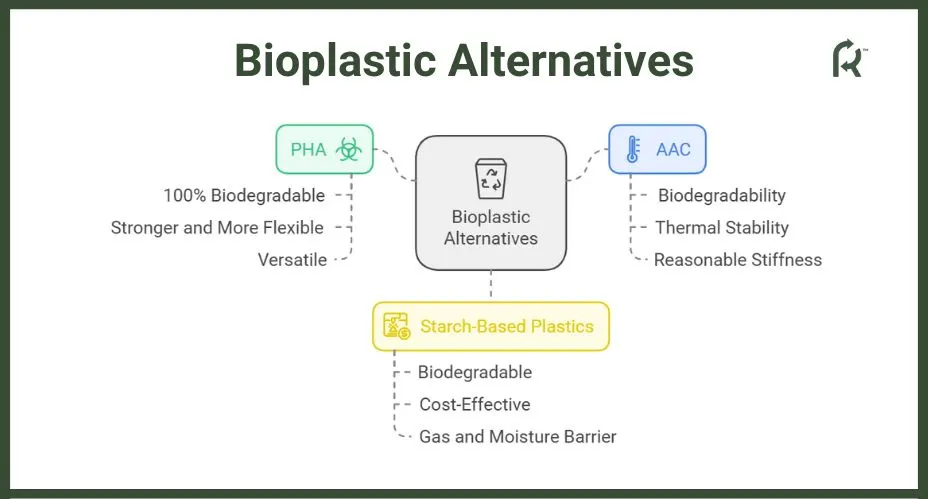

PHA or Polyhydroxyalkanoates

PHAs are biodegradable bioplastics made with the aid of microorganisms, like bacteria. They’re extracted from the bacteria themselves. The resulting PHAs are purified and refined into a strong, durable, and flexible polymer with many interesting advantages. Here are just some ways in which PHAs excel over PLA plastics:

- 100% Biodegradable: PHAs are much easier to break down than PLAs. They don’t need industrial conditions and can break down in mere months in landfills or water.

- Stronger and More Flexible: Mechanically speaking, PHAs have the edge over PLA plastics. They’re tougher, in most cases, and able to last longer, even in harsh conditions.

- Versatile: The added sustainability benefits and strength of PHAs make them more versatile than PLA plastics.

If you want to know about how PHAs and PLA stack up against each other ion the sustainability and performance fronts, explore our full comparison of PLA vs PHA. REGEN™ offers the best of both worlds. It’s a PHA blended with PLA that optimizes both physical and mechanical properties. Our plastic’s ingredients include wood fibers, natural additives, and biopolymers, with all REGEN™ biodegrading within six months. Discover a practical and eco-friendly plastic with REGEN™.

AAC or Aliphatic-Aromatic Copolyesters

AACs are a form of polymer created through a process called polycondensation. That’s a specific sort of polymerization joining together both aliphatic and aromatic monomers. The result is a plastic-like material with a broad range of properties, like biodegradability, thermal stability, and reasonable stiffness.

Starch-Based Plastics

Starch-based plastics have a starch base that’s extracted from plants, like corn or cassava, and blended with bioplastics, like PLA plastics, PHAs, or PBAT. They’re biodegradable, more cost-effective than a lot of other bioplastics, strong, and work well at keeping out gases and moisture, so they’re excellent for packaging.

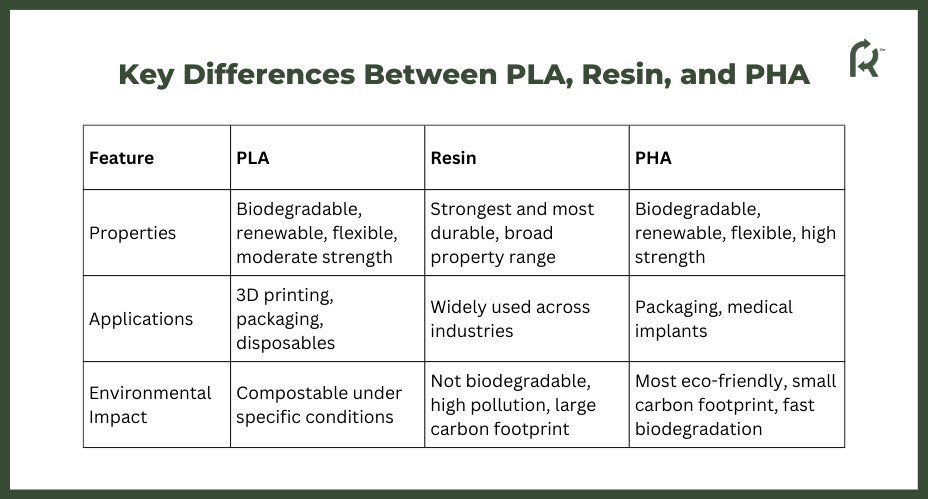

PLA vs. Resin vs. PHA

PLA plastics, resin-based plastics, and PHAs are three of the most popular options for commercial and industrial use. Here’s how they compare:

- Properties: As bioplastics, PHA and PLA plastics are biodegradable and renewable. They exhibit good levels of flexibility and strength, especially PHAs. Resin-based plastics have a very broad range of properties and are usually the strongest and most durable.

- Applications: Some of the uses for PHAs include packaging and medical implants. PLAs, meanwhile, are common in 3D printing, packaging, and disposables. Resin-based plastics are arguably even more versatile, with a rich history of use across numerous industries.

- Environmental Impacts: Of the trio, PHA is the most eco-friendly. It’s got a small carbon footprint and fast biodegradation. PLAs are also compostable in the right conditions. Resins are not biodegradable, cause a lot of pollution, and leave a big carbon footprint.

Let’s say you need to choose between PLAs, PHAs, and resin plastics. It’s recommended not to rush in, pick blindly, or follow trends. Consider your brand’s own needs and objectives.

If you need the strongest, longest-lasting plastics, resin is the way to go, but it comes at both financial and ecological costs. PHAs and PLAs are capable of many of the same things as resins without the same negative impact.

Strategies for Implementing Eco-Friendly Packaging

Switching from conventional packaging to more eco-friendly alternatives is a smart move. It allows brands to show off their eco credentials and attract green-minded customers. It’s also a valuable move towards a happier, healthier world. But it’s a move you’ll want to make with care and consideration to avoid typical pitfalls.

- Material Selection: Prioritize materials that are renewable, leave a minimal carbon footprint, and exhibit easy, rapid biodegradability.

- Packaging Design: Reassess your packaging design and look for ways to minimize the amount of material you have to use.

- Communicate: Let consumers and partners know about your sustainable packaging and advise them on the best ways to reuse or dispose of it.

Design Considerations

- Size: Aim to reduce your packaging size to as much as possible so that you can use fewer materials.

- Weight: Look to lighten your packaging load to minimize its carbon footprint.

- Labeling: Add labels to packaging so consumers know how to dispose of it or recycle it.

Remember, however, to only make design choices that are viable, cost-effective, and practical for your company. It’s great to have sustainability goals, but you shouldn’t go all-in on sustainability right away if it doesn’t fit your budget. Opt for a gradual shift rather than a sharp and problematic transition.

Consumer Education

Studies show that most consumers want green products and packaging, demonstrated by a 71% rise in searches for green products between 2019 and 2024.

But it’s important for brands to let their buyers know about what sort of packaging they’re using, its benefits, and how to dispose of it. You can use your website, store displays, customer service staff, or social media platforms to share info about your eco-friendly packaging and how it helps the natural world.

Here are some tips to ensure your brand’s values are showcased to consumers:

- Add labels to the packaging to explain where and how you made the packaging.

- Provide clear recycling or disposal instructions.

- Be honest and transparent about your packaging materials to gain the trust of consumers.

Try Out REGEN™ Bioplastics

If you’re seeking something like PLA plastics, but even better, with added sustainability, biodegradability, and mechanical properties, REGEN™ is the answer. Crafted in Canada from renewable resources, REGEN™ is a bio-based, non-toxic, and low-energy-consuming compostable plastic with high strength and durability, the ultimate sustainable alternative to PLA.

Advantages Over PLA

- High-performance: Stronger physical and mechanical properties than PLA plastics.

- Compostable: In accordance with leading composting standards, like ASTM D6400.

- Versatile: Boasts a wider range of uses than PLAs, thanks to its properties.

Check out our TUV Austria-certified biobased plastic today to discover how you can use it for everything from cosmetic packaging to 3D printing.

Key Takeaways

- PLA, or polylactic acid, is a popular and versatile bioplastic with numerous advantages.

- PLA isn’t perfect because of sustainability and biodegradability issues.

- Alternative bioplastics, like PHAs and REGEN™ bioplastic, are superior in key areas.

- It’s important for brands seeking sustainable practices to explore PLA alternatives.

Frequently Asked Questions

Is PLA Plastic Food Safe?

Generally, yes. It’s a non-toxic plastic made from safe, natural sources, and it’s often used in both food packaging and the medical industry, too. However, it’s not 100% food-safe in every situation. It depends on the manufacturing process and whether it includes any additives, which may be toxic.

Is PLA Recyclable?

Yes, but only in the right conditions. Mechanical or chemical treating are the only options for breaking a PLA down into its fundamental components for reuse. The mechanical method is cheaper but has diminishing returns, as the quality of the material drops each time.

Is PLA Better Than Plastic?

In certain ways, yes. It’s more sustainable and better for the environment, being compostable and renewable. However, PLA can’t quite match conventional plastics in performance metrics like temperature resistance and durability.