What are PHAs? A simple question on the surface but one that requires some exploration to answer. PHAs are bioplastics made using natural materials, meaning they’re more eco-friendly than traditional plastics. That eco-friendliness results in wide applications, including food packaging, medical instrument creation, and 3D printing.

Of all the many bioplastics in use today, PHA material ranks among the very best. It offers high flexibility, provides good barrier properties, and exhibits good biocompatibility, among many other characteristics. This opens up many uses for the various types of PHA material in industries like agriculture, medicine, and packaging.

This guide introduces some common varieties of PHA material, outlining their production methods, properties, and some of their many uses.

What Are PHAs (Polyhydroxyalkanoates)?

PHA stands for polyhydroxyalkanoates, and PHA materials are one of the leading varieties of bioplastics. These bioplastics are materials that exhibit similar properties and application potential to conventional plastics without needing fossil fuels to make them and without having such a dramatic and negative impact on the natural world.

Unlike other bioplastics, PHA is made by microorganisms, like bacteria. It is synthesized from bacterial fermentation – the bacteria are given some sort of renewable feedstock (like vegetable oils or even waste materials) – and then left to ferment. That causes PHA synthesis, with the microorganisms storing PHA as an energy reserve that manufacturers can extract.

Recovery comes next, with the PHA being extracted, purified, and processed into various forms. Blending with other biopolymers or natural ingredients, such as wood residues, enables a wide range of real-world applications. PHA is often used in packaging applications, for instance, and presents potential for agricultural use.

Since they’re completely natural in origin and produced from renewable resources, PHAs are important forces in the push for a more sustainable world. PHA material is an alternative to conventional plastics in that it can fulfill many of the same roles while being both biodegradable and compostable – key characteristics that aren’t applicable to traditional petroleum plastics.

To understand how PHAs compare to other bioplastics like PLA on the biodegradability and real-world application fronts, check out our detailed PLA vs PHA comparison guide.

REGEN™’s PHA holds several advantages of PLAs, including being compostable within 180 days and not requiring tracts of agricultural land for production. Discover the eco-friendly benefits of REGEN™ today – Learn More.

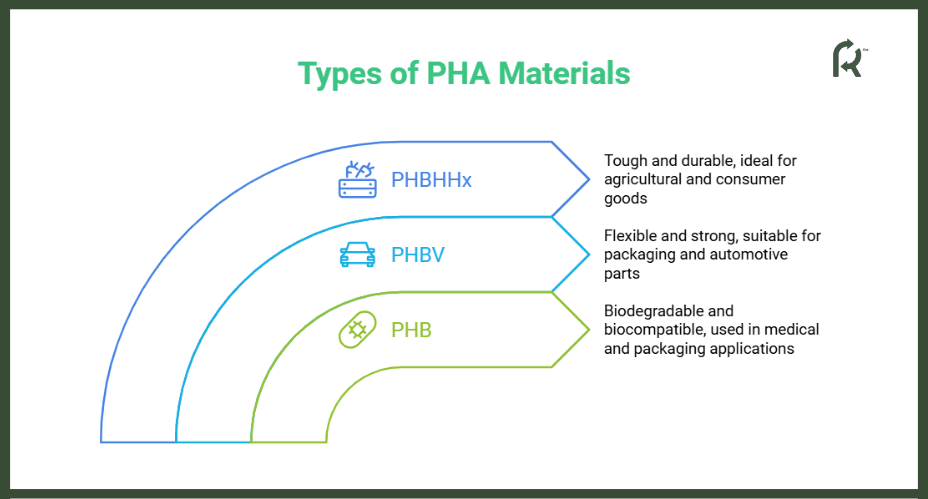

Types of PHA Materials

PHA material comes in different forms. It is compatible with various processing methods, with each manufacturing having its own processes, and offers tunable mechanical properties. This means that we can make all sorts of PHAs with differing levels of strength, flexibility, and chemical composition.

For more information about the unique properties and applications of PHA, you can explore our in-depth article on PHA plastics, highlighting how these bioplastics are revolutionizing sustainable industries.

PHB (polyhydroxybutyrate)

Polyhydroxybutyrate, or PHB, is a form of PHA material that’s made up of linear chains of beta-hydroxybutyrate monomers joined by ester bonds. It’s made by certain forms of bacteria that produce it naturally in specific conditions, like when they’re exposed to high amounts of carbon and low amounts of other elements, like nitrogen.

Some of the properties of PHB include:

- Biodegradable: PHB is fully biodegradable – it’ll break down naturally in various environments.

- Biocompatible: It’s safe for humans, so it is suitable for medical applications.

- Resistant: PHB can handle exposure to a range of chemicals and solvents.

- Non-toxic: It’s safe for people, animals, and the environment, on the whole.

- Thermoplastic: It exhibits thermoplastic properties, allowing for melting and reshaping.

Typical applications of this PHB materials are:

- Packaging, like boxes, bags, liners, and wraps.

- Medical items, like dissolvable sutures.

- Textiles for clothes or other fabrics, like upholstery.

- Consumer items like toys and home items.

PHBV (polyhydroxybutyrate-co-valerate)

PHBV has much in common with PHB. It’s even made with PHB polymers but also mixes in PHV (polyhydroxyvalerate) molecules. This composition adjusts the PHBV’s chemical structure, making it less rigid and defined than PHB’s. It also influences the properties of PHBV, giving it a lower melting point compared to PHB and a bit more flexibility and strength.

Applications for PHBV are:

- Packaging items like thick bags and tough food containers.

- Medical items like tissue scaffolds.

- Automotive parts, such as pieces of car engines or dashboards.

PHBHHx (poly(3-hydroxybutyrate-co-3-hydroxyhexanoate))

PHBHHx is a combination of a PHB and PHHx (polyhydroxyhexanoate). As with other types of PHA material, it’s made by bacteria exposed to specific, controlled conditions, triggering the synthesis of this material. PHBHHx offers a balanced mix of properties, like a high melting point, biodegradability, flexibility, and superior toughness to PHB.

Applications include:

- Packaging bags and containers that should last longer than PHB options.

- Agricultural products like films, planting pots, and liners.

- Consumer goods, such as PHBHHx require similar processing and shaping techniques as conventional plastics.

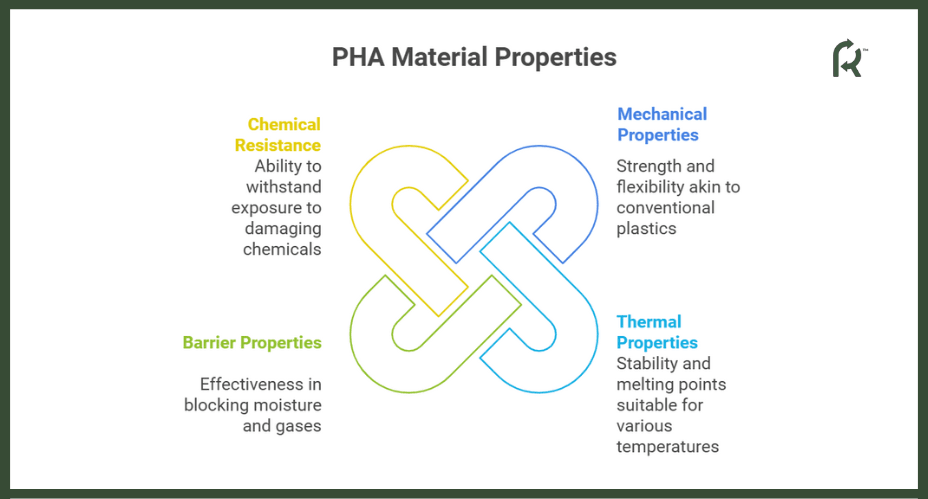

Properties of PHA Materials

PHA plastics are becoming popular in many industries across the globe, and a large part of that popularity is down to PHA’s rich mix of desirable characteristics. Being aware of these characteristics – and knowing which ones to prioritize – is crucial when selecting and working with PHA material in any format.

Mechanical Properties

From a mechanical standpoint – tensile strength, elasticity, etc. – PHA material has much in common with conventional plastics. It’s strong, durable, and flexible.

It may deform under duress but can often regain its initial shape afterward, and hardness levels may vary depending on how it’s made and its specific molecular structure.

Thermal Properties

Thermal stability refers to how well a material copes at increasing temperatures. This is an area where PHA material can vary quite a lot, depending on how it’s made – PHB, for instance, has a higher melting point than PHBV.

Typical melting points for PHAs range from around 140 to 180 Celsius, which opens opportunities for the use of these materials in reasonably hot environments. However, they are at risk of losing their strength and shape when exposed to ovens and high-temperature industrial uses.

Barrier Properties

In a nutshell, barrier properties refer to how well a material acts as a barrier, blocking out moisture and gasses. Some types of PHA materials are particularly strong in this aspect. This makes them ideal for food wraps and containers, blocking out water and gasses that could impair the quality or flavor of the food and extending its shelf-life.

Chemical Resistance

Chemical resistance refers to how well substances withstand exposure to chemicals that might damage or deteriorate them. PHAs generally have reasonable chemical resistance. That makes them great for packaging situations where they might be exposed to acidic liquids, for example, or even in the medical sector, where they may encounter bodily fluids.

Applications of PHA 3D Filament

PHA material is often processed into a 3D printing filament, which is then formed into all sorts of products. Let’s take a look at some notable examples of industries that have embraced PHA material and use it regularly.

Packaging

Packaging is the No. 1 use for PHA material from the perspective of sustainability and protecting the planet. For years, packaging materials like plastic food containers and water bottles have caused untold devastation in the natural world. However, PHA provides the ideal alternative with its key eco characteristics, such as compostability and renewability. It’s perfect for brands who want to become greener and cut down their carbon footprint.

The best part is that PHA packaging materials aren’t weak or flimsy. They’re strong and flexible, like conventional plastic packaging. In a similar fashion to PLA plastics, we can form PHA into boxes, bags, liners, bottles, and more. It’s food-safe, too, so it can house food and drink items, and it’s non-toxic for people and the planet.

Agriculture

The world of agriculture is also shifting away from conventional plastics and onto bioplastics, like PHAs, which offer films and fibers useful for farming. For example, in fields, PHA mulch films can cover up the soil surrounding plants, guarding against erosion and the leaching of nutrients by rainfall and storms. These films also suppress weed growth and keep the soil warmer in winter.

Other uses for PHA material in agriculture include seed coatings, which help seeds sprout more efficiently and have a better chance of growing big and strong, and pot linings, which can break down and release nutrients into the soil naturally as they do.

Medical

PHA plastics have two major characteristics that make them a fine fit for medical applications. They’re biocompatible – they’re generally well-received by the human body and unlikely to trigger adverse reactions. They’re also bioresorbable – they’ll break down within the body naturally over time, so they don’t have to be removed surgically or via other means.

Thanks to this, PHA is suitable for single-use products in medical operations, like sutures to stitch surgical wounds that dissolve over time. Tissue scaffolding and drug delivery system manufacturers demonstrate further uses for PHAs.

Other Applications

Beyond the applications and industries listed above, PHA material has other established and emerging uses. It can help make parts of consumer goods, for example, like toys or kitchen items.

Some of the stronger sorts of PHAs are also suitable for making automotive parts or even bits of electronic devices. Further advancements open up the potential for more wide-ranging uses in the years to come.

However, since it has a high production cost and faces challenges in large-scale production, PHA material still has some way to go. Researchers will need to find new, more efficient ways of developing and working with it than existing methods. This could open many doors for PHA application in more industries while also making this material even more ecologically friendly and safe.

Importance of PHA Material in Biodegradable Plastics

We’ve discussed factors like the strength and flexibility of PHA material. Let’s explore its environmental advantages. Renewable resources lie at the heart of the PHA production process, meaning there’s no finite supply of PHA – we can keep on making it for generations to come without destroying the natural world.

PHA is biodegradable, too. It’ll break down naturally with the aid of microbes in a matter of months. That means you could toss PHA bags and other items into landfills without worrying about them staying there for decades, like conventional plastics. It decomposes in marine environments, too, so it won’t poison waterways and rivers like other substances.

Due to its manufacturing process, PHA material has a much smaller carbon footprint than petroleum plastics. It’s not perfect – we still have to use resources and energy to make it – but from an environmental perspective, it’s better than the plastics of the past. This makes it a major player both in the present and in the future of sustainable materials.

If you’re interested in learning more about companies at the forefront of PHA production, read our overview of the top PHA manufacturers who are pioneering sustainable plastic solutions. And if you’re looking for a strong and versatile alternative to traditional plastics, explore REGEN™ to discover how compostable plastics are the answer to your biodegradable packaging needs.

Why REGEN™?

Our blended PHA is ASTM D6400-certified for compostability and TUV Austria-certified as a biobased plastic made using raw renewable materials.

That sets it apart from PLAs – they need industrial composting to biodegrade. We keep our secret ingredient hidden, but REGEN™ is so environmentally friendly that it breaks down within 180 days, so you don’t have to worry about your plastic use impacting the environment – Learn More Today

Key Takeaways

- PHA is a plastic-like material made from microorganisms, as bacteria

- It comes in a range of forms, like PHB and PHBV

- Different types of PHA material have different characteristics and uses

- Some of the most common applications of PHAs include packaging, medicine, and agriculture

- PHA is one of the most environmentally significant materials thanks to its eco-friendly qualities

Frequently Asked Questions

Can PHA Materials Be Recycled?

Yes, PHA material is recyclable through a range of methods, and scientists are looking to uncover even more efficient options. Mechanical recycling, in which the PHA is physically broken down and then reshaping, is possible. You can also use chemicals to break the PHA polymers down into monomers. PHA material is also biodegradable, so you can also leave it to degrade naturally over time.

Do PHA Materials Have Any Negative Impact on the Environment?

Yes. They have a much lower environmental impact than conventional plastics and a smaller carbon footprint, too, but they’re not 100% ecologically sound. It takes energy and resources to create them like the plant sugars or waste materials to feed the bacteria, with further energy required for the PHA disposal process if you take the mechanical or chemical options.

Is It Possible to Produce PHA Materials from Renewable Resources?

Absolutely. The majority of PHA material comes from renewable resources. Bacteria synthesize the material upon being fed renewables, like agricultural waste, plant sugars, and vegetable oils. Even wastewater, which is 100% renewable, can be part of the PHA material production process.