Hard-to-recycle plastics, such as polyethylene terephthalate (PET) and multi-layer packaging used in bottles, containers, and bags, present significant challenges to a recycling facility.

Despite high recycling rates for PET bottles, many packaging materials still face low recovery due to contamination, which increases recycling costs and complicates collection and sorting. With over 400 million tons of plastic produced annually and a recycling rate under 10% (OECD), most end up in landfills or incinerators, harming the environment.

REGEN™ combats this problem with advanced bioplastics whose origin of renewable sources allows for reducing fossil fuel reliance and improved recyclability. These products promote a sustainable lifecycle by replacing recycling with decomposing.

Furthermore, these bioplastics break down into reusable molecular components by supporting advanced technologies like chemical recycling. REGEN™ emphasizes consumer education and drives standardized recycling guidelines, transforming hard-to-recycle plastics into a pathway for sustainability.

What are Hard-to-Recycle Plastics?

Due to their composition, structure, or chemical properties, hard-to-recycle plastics cannot be quickly processed using conventional recycling methods.

Examples include thermoset plastics, multilayer packaging, and specific foams, such as expanded polystyrene (EPS) lack widespread recycling infrastructure and aren’t widely recyclable. Instead, they require specialized processes and innovative solutions for recycling or repurposing, making them a significant challenge in waste management systems.

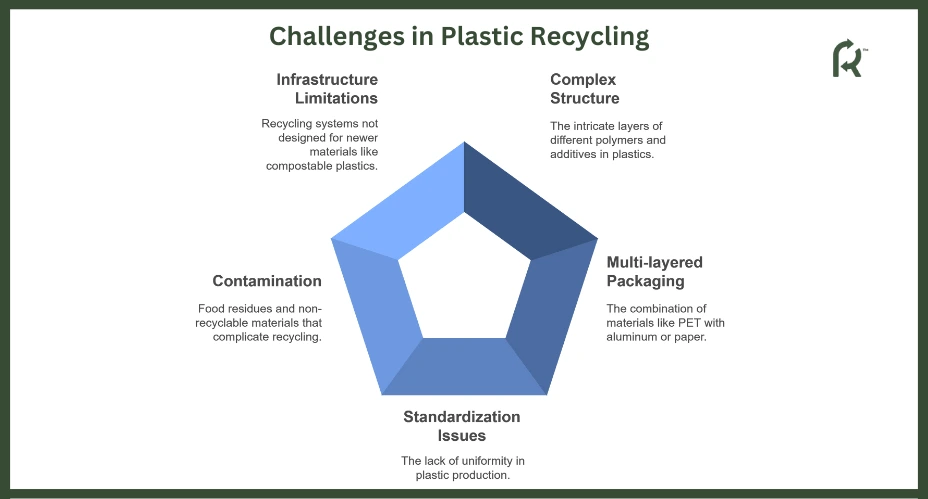

What Makes Plastic Hard to Recycle?

Recycling plastics is challenging due to their complex structure, with layers of different polymers or additives that are difficult to separate. Multi-layered packaging, which combines materials like PET with aluminum or paper, creates non-recyclable composites.

The lack of standardization in plastic production and contamination from food residues or non-recyclable materials further complicates recycling.

Recycling infrastructure is not designed for newer materials like compostable plastics, which are meant to decompose naturally, but consumer confusion over disposal guidelines still leads to contamination in recycling streams.

To improve recycling, better-sorting technology, more transparent labeling, and developing recyclable materials, supported by collaboration across industries, are essential.

What are the Complexities of Recycling Plastics?

Recycling plastics is challenging due to contamination, sorting issues, and processing difficulties. Contaminants like food residues or chemicals often interfere with the quality of recycled plastic.

Meanwhile, the variety of plastic types and their recycling processes make sorting inefficient. Additionally, plastics usually degrade during recycling, limiting their reuse and making recycling more energy-intensive and costly than virgin materials.

Innovations like REGEN™’s PHA products offer a solution. PHA is biodegradable, reducing plastic pollution and simplifying recycling. Unlike many conventional plastics, it doesn’t require complex sorting and is more compatible with existing systems. Made from renewable biomass, it enables the reduction of fossil fuel reliance, promoting sustainable waste management.

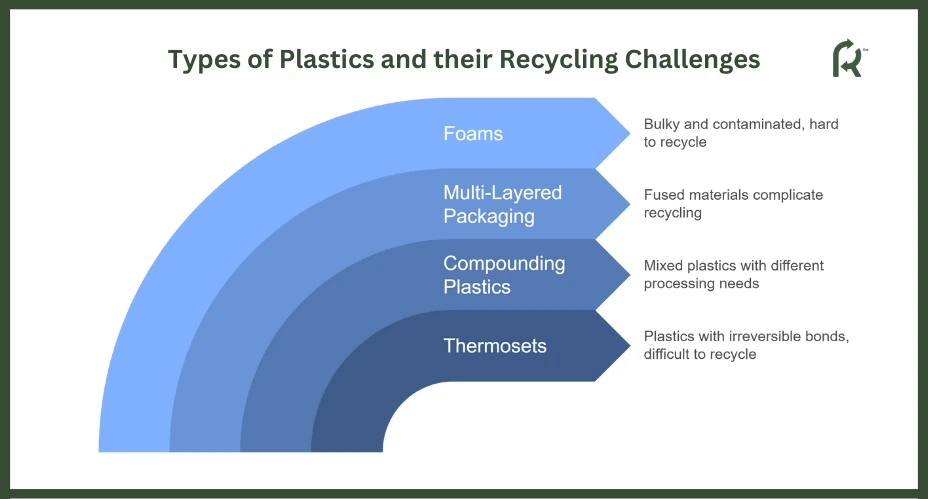

Types of Plastics and their Recycling Challenges

Recycling plastics is challenging due to their complex structural properties, with layers of different polymers or additives that are difficult to separate. Multi-layered packaging, which combines materials like PET with aluminum or paper, creates non-recyclable composites.

The lack of standardization in plastic production and contamination from food residues or non-recyclable materials further complicates recycling.

1. Thermosets

Thermoset plastics are difficult to recycle due to their unique chemical structure. Unlike thermoplastics, which can be melted and reshaped, thermosets undergo an irreversible curing process that creates solid and cross-linked bonds.

Heat or pressure cannot break these bonds, making conventional recycling methods like melting and extrusion unfeasible. As a result, thermoset plastics are often discarded in landfills or incinerated. Advanced recycling technologies, such as chemical or biodegradable alternatives, are needed to improve sustainability.

2. Compounding Plastics

Recycling compounded plastics is challenging, especially when different types, like polyethylene, polypropylene, or polystyrene, are mixed. Each plastic requires different processing methods and additives or coatings further complicate recycling, often resulting in contamination or lower-quality recycled materials.

REGEN™ addresses these issues with single-source, compostable solutions that eliminate the need for complex sorting. Unlike compounded plastics, REGEN™ products are both recyclable and biodegradable, breaking down naturally and reducing reliance on traditional recycling systems. This simplifies the process, reduces contamination, and promotes a more eco-friendly approach to plastic waste management.

3. Multi-Layered Packaging

Recycling multi-layered plastic packaging is challenging due to combining different materials like plastics, aluminum, and paper, each with distinct recycling needs.

These layers are often fused, making separation difficult, and many recycling facilities aren’t equipped for such complexity, leading to packaging being discarded in landfills or incinerators. Using a unified material, REGEN™ biodegradable design ensures the packaging breaks down naturally, enhancing sustainability.

4. Foams

Recycling foam plastics, like polystyrene foam, is challenging because they’re bulky, often contaminated with food scraps, and have a complex chemical makeup.

They also tend to break into small pieces, making recycling even harder. Biodegradable foam alternatives provide a much-needed solution, which naturally breaks down and doesn’t contribute to long-term plastic pollution.

REGEN™ provides compostable materials that replace traditional foam, offering the same protective qualities while being more accessible to process, reducing waste, and supporting sustainable packaging and design.

REGEN™ Solution to Recycle Plastic

Plastic recycling faces challenges due to material complexity, contamination, and processing difficulties. However, with innovations like REGEN™’s compostable materials, businesses can now access eco-friendly alternatives.

Their products, designed for recycling and composting, offer sustainable solutions to hard-to-recycle plastics, like foam and multi-layered materials. These biodegradable products break down naturally, simplifying waste management and promoting a circular economy while helping businesses reduce their environmental impact.

For businesses, switching to REGEN™ materials could reduce their carbon footprint by up to 30% (OECD), contributing to a more sustainable operation.

REGEN™ Innovative Materials

REGEN™ bioplastics stand out for their compostability, meaning they break down naturally in composting environments and their durability, offering high strength for a wide range of uses. They biodegrade faster and are more potent than traditional plastics, making them a great eco-friendly alternative.

These products, made from renewable biomass, also help reduce carbon emissions and dependence on fossil fuels. When switching to REGEN™, businesses should assess application needs, ensure access to proper composting facilities, and collaborate with suppliers to optimize material performance and disposal.

Partnerships and Collaborations

REGEN™ collaborates with eco-conscious manufacturers and partners like Primex, CPFormplast, Novolex, Brewster Plastic, EPL New Zealand, and Profol to drive the adoption of compostable bioplastics. These partnerships help integrate REGEN™ materials into production processes, enhancing compostability and supporting shifting away from traditional plastics.

By collaborating and sharing knowledge, REGEN™ and its partners help reduce plastic waste and meet the increasing demand for sustainable, compostable solutions. Together, they’re driving the shift toward a circular economy and offering more eco-friendly packaging alternatives.

Key Takeaways

- Research by experts and companies in the United States and worldwide is focused on improving contamination management and reducing the amount of non-recyclable items entering the waste stream.

- As communities, researchers, and businesses work together to address these issues, their responsibility to improve recycling systems and increase the percentage of recycled materials in the market becomes ever more urgent.

- REGEN™ provides a powerful alternative by offering compostable, high-performance bioplastics that biodegrade naturally, eliminating the need for recycling.

- Through strategic collaborations with eco-conscious brands, REGEN™ is helping to reduce plastic waste and support the transition to sustainable packaging solutions for a cleaner future.

Frequently Asked Questions

What is the Most Difficult Plastic to Recycle?

The most difficult plastics to recycle are thermosets and multi-layer packaging. Thermosets are problematic because their chemical structure becomes irreversible once they are molded and cured, preventing them from being melted down and reformed like other plastics.

Multi-layer packaging, often used in food and beverage products, combines different materials such as plastics, aluminum, and paper, making it nearly impossible to separate and recycle. These complex structures create significant challenges for recycling systems.

REGEN™ offers a solution with its compostable bioplastics, which provide an alternative to these hard-to-recycle materials. By offering biodegradable options made from renewable sources, REGEN™ simplifies waste management and reduces reliance on traditional recycling processes.

Which Plastic Cannot Be Recycled?

Certain plastics, such as thermosets, polystyrene (PS), and multi-layer packaging, are typically not recyclable. Thermosets undergo an irreversible chemical process that makes them rigid and unable to be remelted or reshaped.

At the same time, polystyrene and multi-layered plastics often contain additives or combined materials that make them difficult to separate during recycling. As a result, these plastics usually end up in landfills or incinerators.

REGEN™ offers a sustainable alternative with its biodegradable bioplastics, designed to break down naturally and compost without leaving harmful residues. These compostable materials provide an eco-friendly solution, helping businesses reduce their environmental impact while eliminating the need for complex recycling processes.

What is a Major Problem in Plastics Recycling?

One of the biggest challenges in plastic recycling is contamination. Food residues, oils, and other contaminants can reduce the quality of recycled materials, making them harder to reuse.

The complexity of multi-layered packaging and plastics with added fillers, dyes, or coatings also complicates sorting and processing. This often results in lower-quality recycled plastics or materials that can’t be recycled.

REGEN™ offers an alternative solution to these problems with its compostable bioplastics, accessible from complex additives and designed to biodegrade quickly. Providing a simple, eco-friendly alternative, REGEN™ helps reduce contamination, streamline waste management, and promote a more sustainable approach to packaging and disposal.