Brands need to ensure they’re making a positive environmental impact while satisfying environmentally-conscious consumers. Compostable packaging materials provide one way to do this. Compostable envelopes, stickers, mailers, bags, pouches, and more are all ideal alternatives to plastics.

Choosing compostable materials reduces landfill waste and is an environmentally responsible choice that supports circular economy movements. This guide shows how making packaging compostable contributes to sustainability and represents an innovative choice for brands.

- What Is a Compostable Packaging Material?

- Top 5 Compostable Materials for Packaging

- Pros and Cons of Compostable Packaging

- The Difference Between Compostable and Biodegradable Packaging

- Benefits of PHAs and Bioplastics: How Can Compostable Packaging Reduce Impact on the Environment?

- Challenges and Future of Compostable Packaging

- Key Takeaways

- Frequently Asked Questions

What Is a Compostable Packaging Material?

Compostable packaging materials are made from organic materials or derived from organic sources. Composting the materials means exposing them to particular levels of heat, moisture, and, in some cases, microorganisms. The material breaks down into natural elements, including non-toxic biomass that’s safe for the environment.

However, packaging manufacturers can’t simply state that their products are compostable. To receive certification, they must pass standards that assess how compostable the material is.

In North America, many of these standards come from the American Society for Testing and Materials (ASTM). There are also some from the International Organization for Standardization (ISO).

Common certifications and standards brands may see applied to materials include:

- ASTM D6400: This standard uses a four-part test to determine whether a plastic can be classed as compostable. To gain this standardization certificate, the material must break down under aerobic composting, combining oxygen, bacteria, and heat. It’s also critical that the material decomposes in compost facilities within 180 days.

- ISO 17088: The ISO equivalent includes similar standards. It also specifies that the material minimizes environmental impact by ensuring no adverse effects on plants and animals.

These standards tell buyers that the material is certified compostable and complies with sustainability standards. Seeing these certifications on plastic-free or bioplastic packaging lets businesses know they’re buying packaging that supports eco-friendly practices.

To further understand how these certifications impact the viability and adoption of compostable packaging, dive deeper into the array of commercial compostable solutions available. This resource provides an extensive look at how businesses can adopt these materials to enhance sustainability.

Top 5 Compostable Materials for Packaging

Which compostable solution best replaces traditional packaging? In this next section, we’ve highlighted five materials that are optimal for sustainable packaging. Each is plant-based or plant-derived in origin and will degrade within a relatively short time compared to conventional plastics.

Any company that transitions to these alternative packaging choices is making a commitment to help the planet.

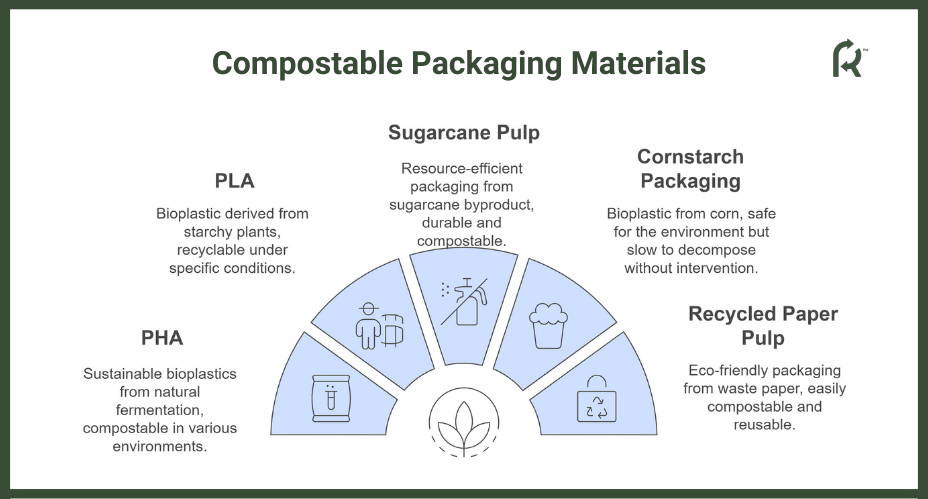

PHA (Polyhydroxyalkanoates)

PHAs (polyhydroxyalkanoates) are uniquely sustainable bioplastics that leverage the natural fermentation of organic material. This fermentation occurs naturally, and PHA manufacturers have scaled that process to produce versatile polymers. These polymers look, feel, and behave like conventional plastics yet are completely compostable.

Many companies are discovering PHA’s superiority over other bioplastic alternatives. It biodegrades in a fraction of the time and can decompose in both industrial and natural soil or marine environments. Because it’s so easy to dispose of, it reduces the need for landfill sites and can even give back to the planet by producing nutrient-rich compost.

PHA is sustainable throughout its lifecycle, from production to disposal, making it the choice for businesses looking to reduce their environmental footprint.

PLA (Polylactic Acid)

PLA (polylactic acid) is another bioplastic that was discovered in the 1930s. It’s derived from the sugars found in starchy plants like cassava, corn, or sugarcane.

To make PLA, the organic raw material is introduced to heat and sulfur dioxide. The combination of heat and chemicals splits the starch from other constituents to ready it for bacterial fermentation.

PLA is used as a packaging material across a wide range of industries. PLA is recyclable as it’s a thermoplastic, so it can be reformed when heated. It can be composted, but only under highly specific industrial conditions.

Sugarcane Pulp or Bagasse

Bagasse is a byproduct of sugarcane production and, therefore, a resource-efficient way to produce green, compostable packaging. The pulp is pressed and dried into various forms and is very similar in appearance to paper or cardboard. However, bagasse-based packaging can be more durable than paper.

The environmental benefits of using sugarcane pulp over traditional materials include:

- Using bagasse supports waste reduction efforts

- Bagasse decomposes in a few weeks in industrial composting facilities

- However, it won’t biodegrade quickly without industrial composting intervention.

- No additional land is required to grow bagasse as it’s a natural byproduct

- Sugarcane grows faster than trees, meaning bagasse is more readily available than wood pulp-based products

Cornstarch Packaging

Cornstarch packaging is often marketed as new and innovative, but in fact, it’s a type of PLA (polylactic acid) that has been around since the 1930s. PLA is created using corn (or other starchy crops) as a base. This undergoes bacterial fermentation to produce pellets of bioplastic. These are then heated and molded to the desired shape and consistency.

PLA is safe for the environment in that it can be industrially composted into water, gas, and biomass, which returns nutrients to the soil. However, without specialist intervention, PLA can take 80 years to break down.

Products commonly packaged using cornstarch-based materials include:

- Food packaging in various formats

- Takeout containers

- Lidded cups

- Films such as those found on envelopes or pre-packed sandwiches

- Beverage cartons

Corrugated and Paper Boxes

Corrugated cardboard and paper are both made from wood pulp or waste-reducing recycled paper pulp. The pulp is treated and squeezed to remove as much water as possible before machines convert it into the desired shape.

Box manufacturers utilize smooth, chemically treated paper for the outside of the box and rough, cheaper paper for the inner layers. Paper is also made into air-filled tubes called flutes which are layered to make the corrugated cardboard.

The advantages of corrugated boxes include:

- They’re lighter than denser cardboard boxes or wooden crates, thanks to the layers of air

- Waste can be processed naturally with ease as card and paper can go in any composter

- Cardboard is easy to print with any design or logo

Recycled Paper Pulp

Recycled paper pulp utilizes previously used waste paper to make new products ranging from envelopes to fruit packaging. Paper is shredded and mixed with water until it becomes a slurry.

Manufacturers develop molds to match their clients’ needs and then wet-press the pulp into them. They transform this wet pulp into a sturdy alternative to plastic with the use of industrial dryers.

Once used, this type of packaging is easy to break down and re-form into new shapes for new uses.

Some of the sustainability benefits of using recycled paper pulp include:

- It’s a simple way to make packaging compostable

- Paper pulp is easily sourced thanks to the wide use of paper products

- There’s a long life cycle as paper pulp can be reused over and over

- At the end of its life, paper pulp can go into any compost facility

Pros and Cons of Compostable Packaging

Making packaging compostable has numerous benefits for the environment and helps brands move toward their net zero aspirations. However, like all materials, some compostable choices have their limitations.

Pros

- Compostable packaging reduces the volume of plastic that ends up in landfill sites.

- This reduces the amount of toxic chemicals produced by landfill sites and protects local ecosystems, making water runoff cleaner and safer. PHA-based bioplastics decompose in warm, moist environments and produce zero harmful chemicals during the process.

- Using fewer fossil-fuel-based plastics also reduces the amount of microplastics in the environment

- Consumers prefer goods that are certified as sustainable or made from renewable sources.

- Many compostable materials are as tough and durable as conventional plastics.

- Compostable packaging materials reduce the reliance on fossil fuels and move society toward a circular economy. PHA-based bioplastics like REGEN™ represent a shift away from reliance on conventional plastics and a move towards more innovative, planet-friendly packaging solutions.

Cons

- Some compostable materials require specialist, industrial compostable facilities

- Storage can be an issue for some compostable materials, as moisture and heat can cause a loss of durability

- Some compostable packaging alternatives are expensive to produce

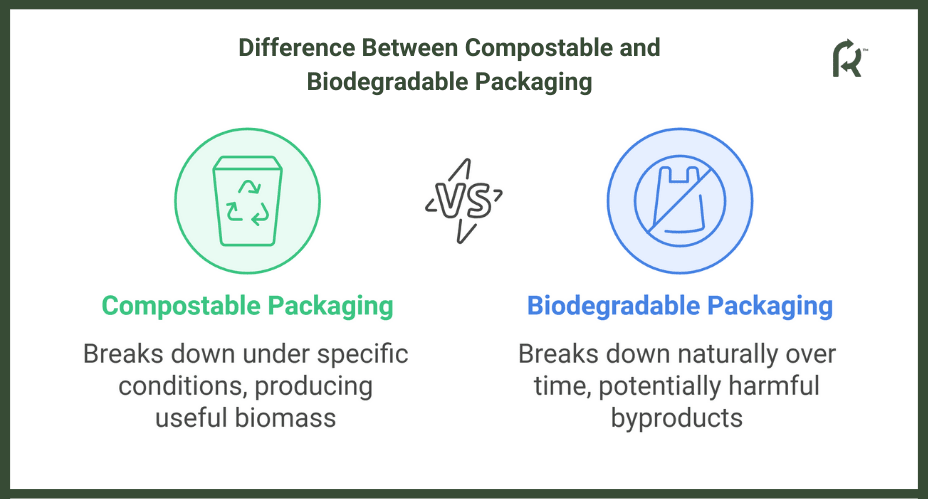

The Difference Between Compostable and Biodegradable Packaging

There’s a common misconception that compostable and biodegradable mean the same things. Furthermore, many people believe that biodegradable and degradable mean the same thing. Most materials are degradable if given enough time. Even conventional plastics degrade over time. However, they produce harmful chemicals that are tricky to dispose of safely.

Biodegradable means that a material will eventually break down into water, CO2 or methane (or both), and its constituent components. For packaging created solely from plant-based materials, this should mean that it produces nutrient-rich biomass. This can be used in several agricultural applications.

Compostable means that the biodegradation process can occur under specific moisture and heat conditions, and within a specific time frame. For certification purposes, a complete breakdown of the product must occur within 180 days.

Understanding the difference between bio-based, biodegradable, and compostable can help brands make smarter environmental choices:

- Bio-based PET (polyethylene terephthalate) is classed as a bioplastic because it’s made from renewable plant-based materials. However, although it can be recycled, it doesn’t biodegrade.

- Photo-degradable and oxo-degradable plastics are often conventional plastics with additives. These additives cause the plastics to break down in the presence of light or oxygen. However, they can still produce microplastics and don’t produce any useful biomass.

- Compostable packaging materials like PHA produce only water, gas, and biomass when placed in industrial composting facilities.

Benefits of PHAs and Bioplastics: How Can Compostable Packaging Reduce Impact on the Environment?

Over 380 million tons of plastic are produced each year, and only 14% of this is recycled. If we continue at this rate, more plastic than ever will end up in the ocean, in our food, and polluting nature. Reliance on plastic also increases a company’s carbon footprint.

Many corporations have signed up to a pledge to cut their greenhouse gas emissions by 30% by 2030, yet some firms have already missed their interim targets. One of the factors driving this failure to adhere to these targets is the resistance to switching away from plastic as a packaging source.

Switching to compostable materials for packaging could vastly reduce the environmental impact of many industries while reducing the carbon footprint of individual companies. Data shows that moving away from petroleum-based plastics could reduce emissions by 69%, and switching to sustainable bioplastics like PHAs could be a huge part of that.

PHA-based, compostable packaging starts life as raw, renewable materials. These are processed into various forms of packaging materials suitable for industries like cosmetics and, in some cases, food. Those are then used for the delivery of goods to customers or in retail stores/warehouses.

Once it reaches its end of life, compostable packaging is placed in industrial composting facilities and reverted into biomass and base components. PHA-based bioplastics like REGEN™ can even harmlessly decompose in soil and marine environments.

Challenges and Future of Compostable Packaging

It’s normal for companies to have concerns about switching to compostable packaging. They may worry that these alternatives aren’t as durable as conventional plastics. There are also concerns about the short-term costs of transforming a company-wide packaging strategy.

PHA-based bioplastics may represent a temporary lift in costs, but the long-term financial benefits outweigh these. Consumers prefer to buy sustainable products, and when brands invest in certified compostable and renewable products like REGEN™, they can use this as a marketing point.

Businesses may also worry about the complexities of disposing of compostable packaging, especially if they’ve never had to deal with it before. While some materials require intensive industrial processes, REGEN™ breaks down in natural environments, making it a low-impact solution for any company.

As techniques become more innovative, the time taken to break packaging materials down will likely shorten. Similarly, companies will more than likely see bioplastics and other compostable materials becoming tougher and more versatile. They’ll become even easier to integrate into existing packaging and shipping strategies.

Choose REGEN™’s PHA Bioplastics for Eco-friendly Packaging

For a prime example of successful implementation of compostable packaging, brands should look to REGEN™. This company has developed a PHA-based bioplastic that breaks down via industrial composting yet is versatile and strong.

REGEN™ PHA-based sustainable bioplastics outperform PLA and other alternatives. This is thanks to their rapid decomposition under both industrial and natural composting conditions.

The non-toxic composition of REGEN™’s unique formula means that no matter how much is broken down, there are never any harmful chemicals.

REGEN™ is kinder to the local environment by protecting ecosystems from toxins and the wider planet by helping with the shift toward a circular economy. REGEN™ is ideal for companies and brands looking to reduce their environmental footprint.

REGEN™ exemplifies sustainable packaging practices by:

- Ensuring all products are certified from renewable sources right across the supply chain

- Aiding companies in their mission to move away from fossil fuel-based plastics

- Providing compostable material that reduces the cost to the planet by reducing plastic pollution

- Combining high-end products with sustainable materials to empower brands to provide excellent customer service via stunning packaging

Cosmetics is just one category REGEN™ is active in, as their operations extend to various other bioplastics applications. As their services offering expands, expect to see more compostable packaging materials available allowing brands to innovate and adopt a greener corporate stance.

Key Takeaways

- Plastic packaging is a problem for the planet, causing pollution that may end up in the ocean.

- Choosing compostable packaging for shipping, packing food, and other packaging applications helps brands become more sustainable.

- Compostable packaging materials range from paper and cardboard to advanced bioplastics like PHA.

- REGEN™ offers PHA-based plastics that are certified compostable, non-toxic, and highly versatile for many packaging applications.

Frequently Asked Questions

How Can You Identify Compostable Packaging?

Truly compostable packaging items should have labels that clearly identify how they are certified compostable. Certifications like ISO 17088 and ASTM D6400 show that the materials have been assessed by experts and proven to be compostable.

Are Compostable Packaging Materials Durable as Plastics?

Many compostable materials are as strong as traditional plastics, but by their nature, they may not last as long. That’s why they are ideal for packaging, which is often single-use or used only a few times. People may benefit from compostable garment bags, for example, as they’re not used too often and are usually replaced as soon as wear and tear shows.

Bioplastics can be made as thick or puncture-resistant as conventional plastics. If kept in warm, moist environments, some compostable material interacts with microorganisms and starts to break down.

Do Compostable Packaging Materials Break Down in Landfills?

Not always. Many companies that provide certified compostable packaging offer materials that rely on aerobic composting that requires oxygen. When those materials are placed into a landfill, they are in an anaerobic environment with no oxygen. This either prevents the material from decomposing or causes the release of toxic chemicals.