Commercial composting is a large-scale technique of converting organic waste into nutrient-rich compost that is specifically intended to manage a large volume of biodegradable materials from industries, businesses, and homes.

Unlike home composters, which can only take small amounts and are limited in the sorts of trash they can process, commercial composting can handle higher volumes and a wider range of organic materials. Composting facilities are outfitted with the required infrastructure and equipment to ensure that the composting process runs smoothly, effectively, and in an environmentally friendly way.

Commercial composting involves the controlled breakdown of organic materials such as food waste, yard waste, and biodegradable packaging. These materials decompose under heat, moisture, and aeration, aided by microbes such as bacteria and fungi. Compost can enhance soil in agricultural and horticultural applications, helping to create a more sustainable environment and reducing the need for chemical fertilizers.

As industries strive to reduce their ecological footprints, integrating compostable solutions becomes imperative. Discover how commercial compostable solutions can facilitate the transition to greener operations by converting organic waste into valuable resources.

- Commercial Composting Is Essential for Waste Management and Environmental Sustainability

- What Does Commercially Compostable Mean?

- What Does “Commercially Compostable Only” Mean?

- Benefits of Commercial Composting

- An Overview of the Commercial Composting Process

- Ingredients for Commercial Compost Production

- Types of Commercial Composting Practices

- Commercial Composting vs. Home Composting

- REGEN™: Paving a Greener Path Forward for Your Business

- Key Takeaways

- Frequently Asked Questions

Commercial Composting Is Essential for Waste Management and Environmental Sustainability

Commercial composting is important for waste management since it reduces the quantity of organic waste that ends up in landfills. Organic items, such as food waste and biodegradable packaging, make up a major amount of garbage that would degrade in landfills without commercial composting, emitting damaging greenhouse gases like methane into the environment.

Composting facilities assist in reducing the industry’s impact on nature by removing organic waste from landfills and converting it into a useful resource that can be utilized in agriculture, landscaping, and gardening. This waste reduction procedure not only saves landfill space but reduces methane generation, resulting in a more environmentally friendly and sustainable waste management system.

In addition to trash reduction, commercial composting promotes sustainability in enterprises and communities. It promotes a circular economy in which materials are reused and repurposed, minimizing the need for raw materials and reducing waste disposal at the end of the product lifecycle.

Composting also promotes environmentally beneficial initiatives, assisting communities in lowering their carbon footprints and encouraging the reuse of renewable resources.

What Does Commercially Compostable Mean?

“Commercially compostable” refers to items that can degrade under the precise conditions found in industrial composting facilities. These products are intended to decompose into natural components, leaving no toxic residues behind.

However, this process requires higher temperatures, regulated moisture levels, and sufficient aeration, which may not be possible in household composting systems.

The primary factors for establishing if a material is compostable in a commercial context include:

- Biodegradation within a certain period under commercial composting conditions.

- No release of dangerous or poisonous substances throughout the composting process.

- Capable of improving soil quality or nutrient content following decomposition.

What Does “Commercially Compostable Only” Mean?

In composting advocacy, the designation “commercially compostable only” implies that the product can only be fully broken down in a commercial composting facility and is not appropriate for home composting.

“Commercially compostable only goods,” such as certain compostable bags and containers, require specialized environmental conditions that household compost piles or bins cannot offer, like higher temperatures and active moisture and aeration control.

While some goods are compostable, they will not decompose properly in a backyard compost pile. Thus, they must be diverted to the appropriate facilities for waste treatment.

Products branded as ‘commercially biodegradable only’ include

- Compostable coffee cups and lids.

- Compostable packing materials.

- Compostable food waste bags.

- Compostable cutlery.

Benefits of Commercial Composting

Environmental Benefits:

- Decreases landfill usage.

- Reduces greenhouse gas emissions.

- Enhances soil quality and fertility.

- Lowers the requirement for chemical fertilizers.

- Helps recycle organic waste such as food and yard debris.

- Saves water by increasing soil moisture retention.

Economic and Social Benefits:

Commercial composting helps local economies by creating green jobs, especially in the waste and resource management industries. Composting facilities usually require personnel to collect, sort, and oversee the composting process, which promotes local employment.

Furthermore, commercial composting promotes community involvement, encouraging both customers and companies to embrace sustainable practices. By lowering the quantity of garbage delivered to landfills, municipalities save money on landfill upkeep and contribute to long-term environmental sustainability.

While exploring the advantages of commercial composting, understanding the role of the fastest decomposing materials is key. Learn about the fastest biodegradable materials that significantly speed up the composting process, enhancing efficiency and environmental benefits.

An Overview of the Commercial Composting Process

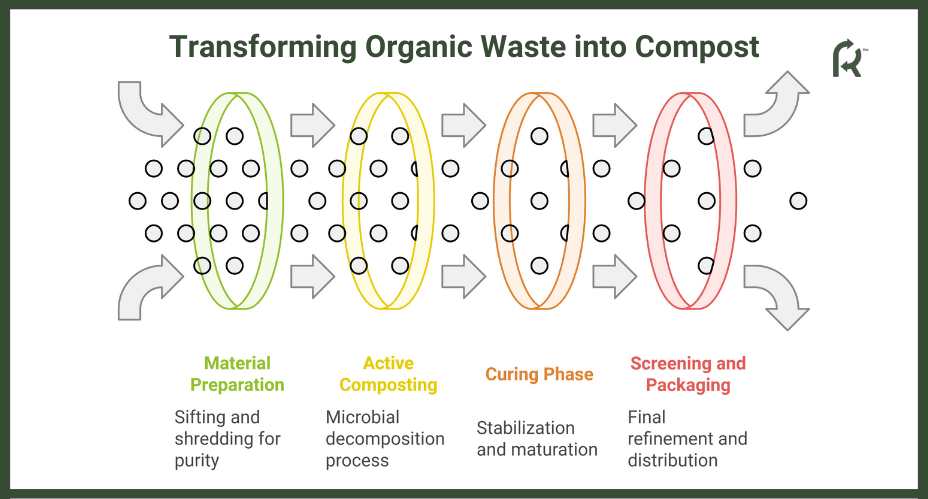

The commercial composting process consists of several phases, each of which is crucial to converting organic waste into useful compost. The process starts with material collection and preparation and then moves on to active composting, curing, screening, and packing.

Collection Methods and Preparation

The first stage is collecting organic materials from diverse sources, including food waste, compostable packaging materials, and yard clippings. These materials are then processed to eliminate impurities and non-biodegradable elements. The process is as follows:

- Organic garbage is collected from both enterprises and homes.

- The materials are sifted to eliminate plastics, metals, and other impurities.

- Organic materials are shredded to enhance surface area and accelerate decomposition.

- The ingredients are moistened and combined to generate the best conditions for composting.

Preparation is critical to ensure the composting process goes smoothly and produces high-quality compost. Removing impurities and carefully combining materials ensures the composting process is more efficient, resulting in a richer finished product.

Active Composting

Active composting is a phase of fast decomposition caused by the activity of microorganisms, such as bacteria, that break down organic materials. This phase is tightly managed to provide the best conditions for breakdown.

The conditions required for active composting include:

- High temperatures (usually 55°C – 65°C).

- Adequate moisture content.

- Adequate aeration to sustain oxygen levels.

During this phase, microbial activity converts organic matter into humus, a stable type of compost. The heat produced during this process also destroys bacteria and weed seeds, rendering the compost suitable for use in agriculture and gardening.

Curing

Curing is the final stage of composting, in which the compost is allowed to stabilize. This permits any residual organic material to decompose further and ensures that the compost is mature before being used.

Factors regulated during the curing phase include:

- Temperature

- Humidity

- Oxygen levels

The curing step is critical for producing high-quality compost that is free of hazardous microorganisms and ready to nourish the soil.

Screening and Packaging

Once fully dried, the compost is screened to eliminate lingering pollutants or big particles. The compost is then bagged and sold commercially or distributed for use in agriculture, landscaping, and for other purposes.

Commercial compost is commonly packaged using the following methods:

- Bulk delivery to farms or landscaping businesses.

- Compost bags for retail sale.

- Specialized packaging for garden centers.

Ingredients for Commercial Compost Production

Food waste, yard clippings, paper, cardboard, and biodegradable packaging are among the most commonly utilized waste materials in commercial composting. Balancing carbon-rich materials (such as paper and cardboard) with nitrogen-rich materials (such as food scraps) is vital for achieving the right carbon-to-nitrogen ratio, which is required for effective breakdown.

Types of Commercial Composting Practices

Commercial composting employs a variety of processes, depending on the size of the operation and the materials treated.

In-Vessel Composting

Advantages:

- Increased breakdown rate due to the regulated conditions.

- Reduces bad smells and bugs.

In-vessel composting is typically used in urban composting facilities and facilities that handle food waste from restaurants and cafeterias.

Static Pile Composting

With static pile composting, organic waste is piled into a heap and left to decompose naturally without frequent turning or aeration. Air pipes or perforated tubes can be inserted into the pile to increase airflow.

Features:

- Low maintenance process, unlike other composting methods that require frequent turning and sometimes the use of heavy machinery.

- Space-efficient due to the compost remaining in a fixed location.

- Natural decomposition uses heat produced by the decomposition process itself.

Static pile composting is ideal in small-scale commercial settings and at schools, small farms, and residences where organic waste is produced steadily and in manageable quantities.

Organic farms or small-scale agricultural operations that produce a mix of plant waste, manure, and other compostable materials, municipal green waste collection points, and businesses involved in bioplastics can also benefit from the simplistic and low-maintenance process of this composting method.

However, there are some limitations. Static pile composting takes considerably longer than other composting methods – from six months to two years, depending on the conditions and materials. The limited options for aeration also increase the risk of uneven decomposition. Having a pile of decomposing matter sitting in one place for an extended period can produce bad smells and become an issue where space is at a premium.

These limitations make this method less suitable for high-volume or commercial composting operations, although effective management of materials and occasional intervention can make it more feasible.

Windrow Composting

This method of composting is commonly used in agricultural settings in the following ways:

- Animal manure management – livestock manure can be mixed with bedding materials like straw or sawdust.

- Composting plant waste, crop residues, and farm-generated organic materials.

- Producing high-quality organic compost or fertilizer, either for on-farm use or for sale.

- Processing agricultural food waste, such as spoiled crops or food-processing byproducts.

- Composting biodegradable materials like compostable films, mulches, packaging, or bioplastics like PHA.

- Killing off weed seeds and soil-borne pathogens in agricultural waste.

Organic waste is placed in long, narrow rows called “windrows”, often several feet high and wide. A key part of the process is the regular turning of the piles, which introduces oxygen to the composting process, ensuring aerobic decomposition and faster breakdown of materials. The regular turning also helps maintain optimal temperatures (typically 130 – 160°F), which is crucial for killing pathogens and weed seeds.

Although it requires regular moisture monitoring, the fact that it can handle both small and large volumes of organic material makes windrow composting suitable for municipal, industrial, and agricultural composting.

Commercial Composting vs. Home Composting

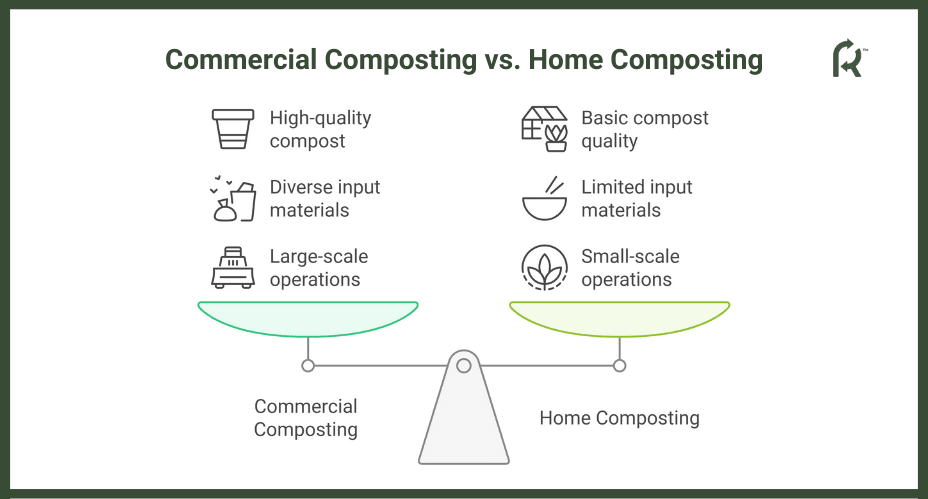

The main differences between commercial and home composting are as follows:

- Scale

Commercial composting can operate at a considerably greater scale than domestic composting. These systems are designed to treat several tons of organic trash every day. This large-scale operation enables more effective handling of community or industrial waste, resulting in a considerable reduction in the amount of garbage that ends up in landfills.

- Input Materials

Unlike home composting, which is typically limited to kitchen scraps and garden waste, commercial composting systems can handle biodegradable packaging, food waste from restaurants, yard trimmings, and even certain types of industrial organic waste. This versatility allows the management of diverse waste streams.

To fully understand how compostable packaging plays a crucial role in the composting process and its benefits for the environment, delve into our detailed guide on compostable packaging materials. This resource explores the variety of materials available and how they contribute to sustainable waste management practices.

- End Products

Commercial composting produces enormous amounts of high-quality compost in a short period of time. This nutrient-dense compost is ideal for improving soil health in agricultural areas, gardens, and landscaping projects.

The quick production cycle of commercial composting offers a consistent supply of soil amendments, mulches, fertilizers, and compost tea. These products promote sustainable agriculture practices and reduce the demand for artificial fertilizers. In addition, some commercial composting techniques break down organic waste anaerobically to create biogas, which may be utilized as a renewable energy source.

Advantages and Challenges:

Commercial composting has a higher waste processing capacity but requires substantial infrastructure and expenditure. Home composting, on the other hand, is undeniably more accessible. However, it is slower and has limited material processing capabilities.

While commercial composting requires access to specialized facilities, REGEN™ works with businesses to ensure their PHA-based packaging can be effectively composted, offering guidance on infrastructure and partnerships with composting services.

Transporting compost from a company to a commercial composting plant is a multi-step operation. Initially, compostable products are collected from the company and placed in appropriate receptacles, such as bins or dumpsters. These containers are usually given by the waste management firm or a commercial composting site. The kind and size of the containers vary according to the amount of biodegradable materials generated by the firm.

It is important to verify that your preferred commercial composting company can handle PHA (Polyhydroxyalkanoates)-based packaging. This is where REGEN™ can help. The firm maintains a list of PHA-approved compostors. It doesn’t matter where in the US your company is based, REGEN™ can source the nearest PHA-approved composting station and put your company in touch with logistics companies that service that station.

When the containers are full, they are collected by specialist trash management equipment like compactors or trucks with lift gates. The collection frequency is determined by the company and can range from daily, weekly, or biweekly pickups. Drivers of these trucks are trained to handle organic materials and deliver them safely and effectively.

After collecting, the compostable materials are transported to a transfer point, unloaded, and reloaded into bigger vehicles like semi-trailer trucks or trains. At the transfer station, materials may be sorted and processed to remove pollutants and enhance compost quality.

Compostable items are transferred from the transfer point to a commercial composting plant. This facility is specially built to manage organic waste, with equipment and methods in place to convert the materials into nutrient-dense compost. The facility may use a variety of composting technologies, including aerobic and anaerobic digestion, windrow composting, and vermicomposting.

When the materials arrive at the commercial composting plant, they are unloaded and processed through many mechanisms, including sorting, grinding, and mixing. The items are subsequently deposited in compost bins or heaps, where microorganisms decompose the organic stuff into compost. Composting can take many weeks or months, depending on temperature, moisture, and oxygen levels.

PHA plastic is a compostable and renewable polymer that may be treated in commercial composting facilities. The method starts with sorting, which separates PHA-containing materials from other biodegradable materials and then shreds them into tiny pieces to improve surface area.

The shredded PHA is combined with other organic materials, such as food scraps and yard clippings, before being deposited in compost bins or windrows. In aerobic circumstances, microorganisms degrade the PHA, which is aided by temperatures ranging from 50 to 60°C (122-140°F) and the introduction of oxygen.

Facilities such as TerraCycle (US), Novamont (Italy), BASF (Germany), and Biomer (UK) specialize in processing PHA. The particular processing processes may differ according to the facility and local requirements. Overall, commercial composting facilities play an important role in removing PHA plastics from landfills and transforming them into useful compost materials.

Throughout the composting process, the facility monitors temperature, moisture, and oxygen levels to ensure the best conditions for decomposition. The completed compost is dried, filtered, and tested for quality and contaminants. Finally, the compost is bagged and marketed to farmers, landscapers, and gardeners as a nutrient-dense soil additive.

Overall, transporting and processing compost from enterprises to commercial composting facilities requires a collaborative effort from waste management firms, transfer stations, and composting facilities. This method is crucial for removing organic waste from landfills and producing compost that promotes sustainable agricultural and landscaping activities.

REGEN™: Paving a Greener Path Forward for Your Business

Implementing commercial compostable solutions and standards can significantly contribute to a company’s sustainability practices, goals, and eco certifications by reducing waste, lowering greenhouse gas emissions, and supporting eco-friendly waste management practices.

Businesses that incorporate commercial composting can improve their environmental impact assessment and demonstrate a commitment to sustainability, both in their sustainability reporting and marketing materials to consumers.

As a result, the incentives for businesses that use the fastest biodegradable material include generating favorable brand awareness, fulfilling rising customer demand for sustainability, and compliance with regulations and industry standards. This environmentally beneficial shift can also result in long-term savings via government subsidies and sustainability certifications.

Businesses that are successfully integrating commercial composting include:

- Cafés and Restaurants

Blue Bottle Coffee is an excellent example of a café that has effectively used commercial composting. They have established a zero waste policy at a number of their sites, including their San Francisco Jackson Square Café. This café diverts 98% of its trash from landfills by composting food scraps and coffee grounds, recycling and utilizing recyclable items.

- Independent and multinational cosmetics and beauty companies

L’Oréal has created a thorough waste reduction program throughout its production locations. Organic waste from product components and cafeteria food scraps are collected at their premises and sent to commercial composting facilities. This not only minimizes trash but also helps them achieve their sustainability goals by converting garbage into excellent compost for use in local agriculture. Their R&D program also aims to use sustainable packaging whenever feasible.

They also adhere to the ‘3Rs’ principle: respect the environment, reduce resources, and replace traditional materials with recyclable and biodegradable alternatives. By 2030, L’Oréal intends to have 100% of its plastic packaging created from recycled or bio-based plastic alternative materials.

- Office buildings

The MaRS Discovery District in Toronto has integrated commercial composting into its waste management system. Organic waste, such as food scraps and coffee grounds, is collected in specific compost containers on each level of its office spaces. A commercial composting service picks up the gathered garbage, lowering these sites’ overall waste impact and contributing to a greener city.

- Large events

San Francisco Marathon, USA, has a zero-waste target, and composting is an important part of its overall waste management approach.

Key Takeaways

- Reduce Waste, Lower Emissions: REGEN™ PHA-based bioplastics are entirely compostable, reducing landfill waste and greenhouse gas emissions.

- Improve Sustainability Metrics: By using compostable packaging, businesses reduce their environmental impact, promote a circular economy, and raise brand recognition.

- Streamlined Composting Process: Commercial composting includes efficient collection, active composting, curing, and screening to ensure complete decomposition.

- REGEN™’s solutions are adaptable to various composting processes (in-vessel, static pile, windrow), allowing them to meet the demands of diverse businesses.

- Economic Advantages: Working with REGEN™ on compostable packaging solutions reduces costs, improves regulatory compliance, and supports long-term sustainability goals.

Frequently Asked Questions

What can be commercially composted?

Food waste, yard clippings, compostable packaging, and paper goods are all appropriate materials for commercial composting.

Are commercially compostable materials recyclable?

Commercially compostable materials are not recyclable in the traditional sense. They are designed to break down through biological processes rather than being reprocessed like traditional recyclables such as plastic or glass.

Is commercially compostable better than plastic?

Commercially compostable materials are an environmentally beneficial alternative to typical plastics since they degrade into natural components without leaving hazardous residues. However, they require the proper composting conditions, which may restrict their total environmental effect in locations without composting facilities.