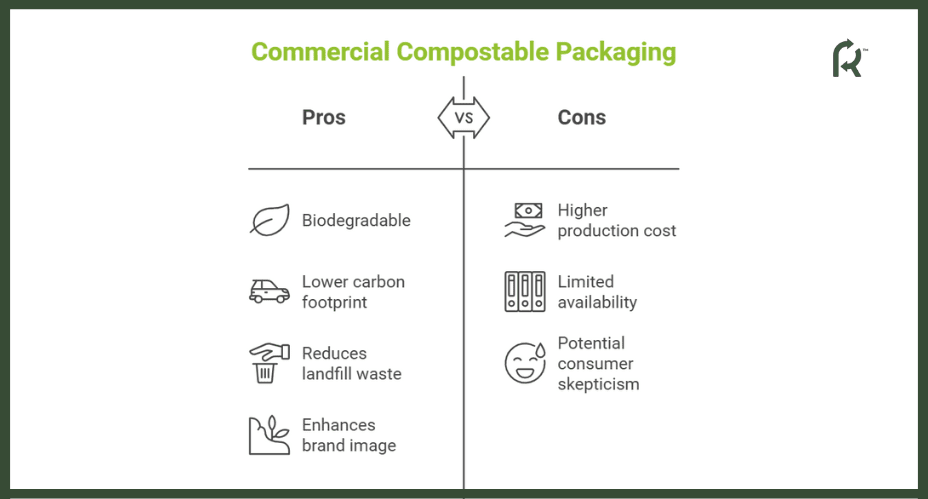

While commercial compostable packaging comes with the benefit of knowing that your packaging minimizes negative environmental impacts, it’s not a perfect solution. You will pay more for compostable packaging and may need to educate your consumers on why this packaging is so beneficial.

Despite those challenges, we’re seeing a trend toward adopting compostable packaging. The average consumer is more eco-aware than ever, with 62% of people saying they “always or often” seek sustainable products. Another benefit of switching to compostable packaging lies – you align your brand with consumer needs.

But you need more information. This guide explores what commercial compostable packaging is, how it’s made, and some of the benefits and challenges it presents.

- What Is Compostable Packaging?

- Understanding Compostability Certifications

- Benefits of Commercial Compostable Packaging

- Challenges of Commercial Compostable Packaging

- How to Address Commercial Compostable Packaging Drawbacks

- Consumers Promoting Compostable Packaging

- Key Takeaways

- Frequently Asked Questions

What Is Compostable Packaging?

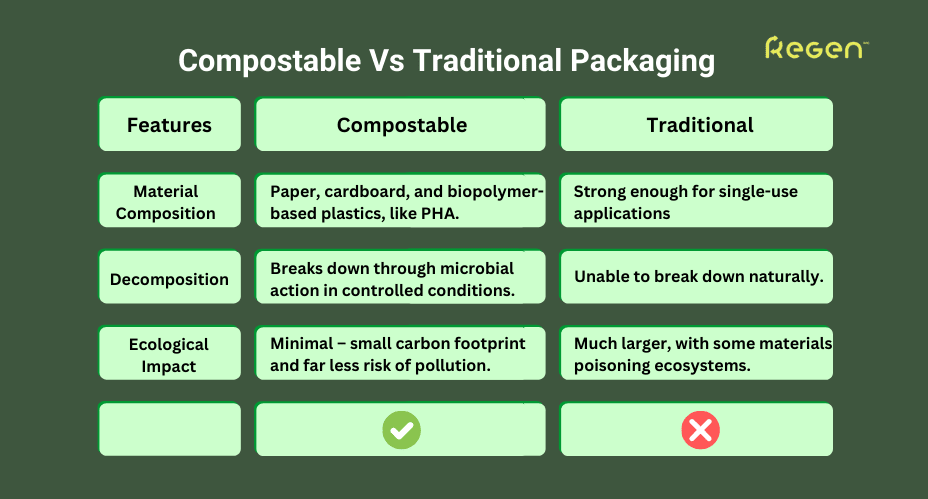

Compostable packaging is any form of packaging that’s able to break down into safe, organic matter without leaving harmful or toxic residues behind. In the right conditions – like industrial composting facilities – such materials break down in a matter of months.

REGEN™ PHA is a good example, as it breaks down in 180 days or less in an industrial setting and also breaks down naturally if placed in a landfill or a humble home compost bin. Examples of compostable packaging options are paper, cardboard, and wood pulp. Compostable plastics, such as PHAs, are also included in this list.

Difference Between Compostable and Traditional Packaging

Certified compostable packaging has clear advantages over traditional varieties. However, there are still some misconceptions about it, like:

- It all decomposes in compost bins. – This is false, as it often needs industrial facilities.

- It’s 100% safe for the environment. – Also false, as compostable materials still take energy to make and resources to dispose of.

If you’re interested in learning more about the types of packaging that can break down into safe organic matter, explore our detailed guide on compostable packaging material, covering the various options available for eco-friendly packaging solutions. REGEN™ carries this certification, as well as being certified as biobased by TUB Austria – Learn More.

Understanding Compostability Certifications

Composting authorities have established strict tests and standards used to determine if a material is “compostable” or not. Such certifications are important to prevent mislabeling of materials or confusion among consumers.

To better understand how industrial composting facilities work and the role they play in the decomposition of packaging materials, check out our article on commercial composting, which explains the process and standards involved.

Commercial Compostability Certification

To pass as commercially compostable, a material undergoes rigorous testing. This testing starts with an analysis, after which the material goes through an industrial composting process to assess how well (if at all) it breaks down. There are various standards around the world, like ASTM D6400 in the U.S. and CAN 0017-088 in Canada, which apply if a material passes the relevant tests.

Home Compostability Certification

Materials go through even more testing to achieve a home compostability certification. They must be able to break down in a usual home compost bin without the controlled conditions of an industrial facility. If they pass, this is good news for brands and consumers, as it means that people can put the materials in their own compost bins and use the nutrients to feed their lawns and yards.

Benefits of Commercial Compostable Packaging

There are many reasons to use commercial compostable packaging over traditional materials. It contributes to lower carbon footprint size, for example, and is suitable for food packaging, agricultural use, consumer products, and more. Let’s take a look at some reasons why to consider transitioning to compostable options.

Environmental Advantages

Compostable packaging provides three benefits to the natural world:

- It’s fully biodegradable and breaks down into safe, natural, non-toxic elements.

- It has a much smaller carbon footprint than materials made with fossil fuels.

- It helps to reduce the amount of long-term waste in landfills and oceans.

By minimizing waste and maximizing the usage and efficiency of renewable resources, compostable packaging aligns with circular economy principles.

It breaks down into natural ingredients that enrich the soil rather than damage it. The soil then provides nutrients for new plants to grow, which compostable package manufacturers can use to create more of their products.

For a closer look at how different packaging types contribute to environmental issues, visit our analysis of the environmental impact of packaging, where we explore the ecological footprint of various materials.

Brand Image and Marketing Appeal

Switching to commercial compostable packaging also improves your brand’s image in the eyes of society and your consumers. Stats show that many people want to shop “green”, choosing eco-friendly brands and products wherever possible, with 42% of consumers rating sustainability as “very important.” So, using this kind of packaging is a good way to prove to your customers that you’re a company committed to sustainable causes.

Potential Cost Savings

Even though it costs more to make, using compostable packaging can save businesses money in the long term. The savings come from disposal and waste management fees.

Instead of sending your packaging waste to landfills or industrial disposal facilities, you could save a small fortune by using packaging that biodegrades naturally and can blend other compostable materials to offer further uses.

In Canada, the U.S., and other nations, there are also government-funded incentives and tax breaks available for companies that use sustainable packaging, like:

- Tax credits

- Tax deductions

- Government grants

Challenges of Commercial Compostable Packaging

While compostable packaging enhances brand eco-friendliness and improves waste management practices, it’s not perfect. It brings new obstacles to the table for businesses to overcome and fresh challenges for industry leaders to solve in regards to price, performance, and other issues. Because of this, the switch to compostable packaging is one that demands careful navigation and management.

Cost and Availability

The first big challenge with commercial compostable packaging is cost. In the majority of cases, this sort of packaging costs more to make and work with than conventional varieties.

There are a couple of reasons for this. Many of the production processes for compostable materials, like PHA plastics, are more resource-intensive and complicated, with higher costs as a result.

The raw materials involved, like plant matter, can cost more than fossil fuels for petroleum plastics. It also costs money to test the material and ensure it complies with composting standards. Accessibility is also an issue. Since compostable packaging isn’t as widespread as conventional packaging, it isn’t as accessible. It has limited infrastructure (a lack of commercial composting locations) and supply chain issues, too.

Performance and Functionality

Another issue with commercial compostable packaging is that it may not always match conventional packaging in performance and functionality.

For example, classic plastic packaging bags and wraps have strong levels of resistance to high temperatures, so you can keep them in warm conditions. Compostable bioplastics, meanwhile, may deform or degrade when exposed to heat.

Traditional packaging materials, like plastics, also tend to be more hard-wearing and able to withstand a wider range of chemicals and conditions. This gives them the edge over compostable alternatives in certain applications.

Commercial composting packaging is getting better, with products like REGEN™ combining PHA bioplastic with biopolymers, wood fibers, and natural additives to create plastics that are as practical as oil-based variants. Learn more today – REGEN™ gives you the best of both worlds.

Consumer Awareness and Education

The general public is becoming aware of environmental issues and sustainable initiatives. However, there are still misconceptions and much confusion regarding commercial compostable packaging – many everyday consumers don’t know how it’s made, how to dispose of it, or its limitations.

It’s important for brands who switch to compostable packaging solutions to educate and inform their audiences on the topic. Brands may need to invest in marketing campaigns to raise awareness of their new compostable boxes, wraps, bags, or containers, as well as educate customers about how to handle and get rid of their packaging once it’s served its purpose.

How to Address Commercial Compostable Packaging Drawbacks

We’ve seen some of the drawbacks of commercial compostable packaging. Let’s now look at emerging and upcoming ways to solve those problems, making the transition to sustainable packaging easier and more seamless for brands, both now and in the future.

Technological Advancements

Research and development is underway to fine-tune and improve compostable packaging solutions. Recent innovations include:

- Improved Materials: New biopolymer blends with impressive mechanical properties to rival conventional plastics are emerging, helping compostable packaging break into more and more industries.

- 3D Printing: The rise of 3D printing in recent years, coupled with the creation of compostable 3D printing filaments, allows manufacturers to create the right kind and size of packaging to suit their exact needs.

- Composting Refinement: Manufacturers, such as BOSK, improve their processes over time, creating packaging that composts faster and is easier to recycle. Such improvements lead to greater efficiency in the composting process and enhance packaging sustainability.

These technological advancements help to overcome some of the aforementioned challenges with commercial compostable packaging. As tech improves, this packaging will become stronger, more versatile, less expensive to make and dispose of, and even kinder to the planet.

Infrastructure Development

A downside with commercial compostable packaging is the lack of infrastructure, like composting facilities and supply chain networks.

Further investment will allow for the creation of more production facilities, which benefits the entire compostable packaging sector. Here are some steps governments can take to ensure the sector achieves the 6.5% compound annual growth rate expected between 2024 and 2030:

- Fund or construct more industrial composting facilities.

- Fund research into finding ways to improve compostable materials.

- Provide subsidies and incentives for businesses to work with compostable packaging.

- Support supply chain development, helping the flow of compostable packaging worldwide.

Consumer Education and Engagement

To solve the issue of consumer awareness and engagement with commercial compostable packaging, businesses and governments could:

- Create public awareness campaigns and advertisements.

- Partner with celebrities or industry leaders to raise awareness.

- Use social media campaigns to engage with younger generations.

- Use packaging labels to inform people about disposal methods for compostable packaging.

Businesses aren’t the only ones responsible for educating the public about this type of packaging. It’s also the responsibility of the media and public-facing organizations to do what they can to educate, inform, raise awareness, and encourage consumers to accept and engage with commercial compostable packaging.

Consumers Promoting Compostable Packaging

Consumers are a huge part of the push towards a more sustainable future. There’s even a new kind of consumer – the “green consumer,” who commits to buying sustainable products and supports eco-conscious brands. Stats show that the number of green consumers is on the rise, with the majority of consumers wanting sustainable goods wherever possible.

It’s in every business’s best interest to consider making the switch to sustainable, commercial compostable packaging. Doing so can help businesses reach a broader audience, bolster the brand’s green credentials, gain new customers, and make more money in the long term while also protecting the planet.

REGEN™ is doing its part to help businesses find eco-friendly packaging solutions to meet rising customer demands for sustainability. Capable of biodegrading within six months, REGEN™ is ASTM D6400, and TUV Austria certified as a biobased and biodegradable packaging material – Learn More Today.

Key Takeaways

- Compostable packaging offers an alternative to traditional packaging. It breaks down under controlled conditions into safe, natural components.

- Made using renewable resources, it is more sustainable than conventional materials.

- Offers applications for multiple industries while allowing businesses to meet increasing demand for green products.

- However, there are challenges with compostable packaging, like its cost, lack of availability, and infrastructure that isn’t well established.

- Businesses and governments must find ways to improve the quality and usefulness of this packaging, along with educating consumers about its uses and benefits.

Frequently Asked Questions

Is Commercial Compostable Packaging Expensive?

Compared to traditional plastic packaging, yes, compostable packaging is quite expensive. This is because of a few different factors, like the more resource-intensive (and costly) production techniques and the need for certification and testing before release to the public. However, as methods improve and this packaging becomes more accessible, costs should drop.

Is Commercial Compostable Packaging the Solution to the Plastic Pollution Crisis?

Not alone, no. Compostable packaging supports sustainability initiatives and reduces the environmental impact of packaging. It decomposes into non-toxic materials and helps reduce landfill waste. But it still has some issues. It’s expensive to make, requires specific infrastructure to use and dispose of, and can even get contaminated by other materials.

Can Compostable Packaging Be Used for All Types of Products?

No, at least not in its current state. This is another of the limitations of compostable packaging. It’s usually not quite as strong or durable as the toughest traditional plastics, and some compostable bioplastics are susceptible to heat deformation, too. It can struggle when exposed to harsh conditions or high temperatures, such as those exceeding 140 degrees Fahrenheit. Chemical contamination also presents challenges for compostable packaging.