In theory, all polymers are biodegradable, as they naturally degrade over time—though this process can take centuries. However, only polymers decomposing within a few months to two years are classified as biodegradable.

These biodegradable polymers represent a sustainable alternative to traditional, non-biodegradable polymers derived from petrochemicals.

Unlike non-biodegradable polymers, which produce microplastics, biodegradable polymers break down through microbial action, degrade into harmless substances, and reduce their environmental footprint.

- What Are Biodegradable Polymers?

- What Are Non-Biodegradable Polymers?

- Biodegradable vs. Non-Biodegradable Polymers: Key Differences

- Pros and Cons of Biodegradable Polymers

- Pros and Cons of Non-Biodegradable Polymers

- How to Choose the Right Polymer for Your Brand

- Key Takeaways

- Frequently Asked Questions

What Are Biodegradable Polymers?

Biodegradable polymers can be made from a variety of wastes and biosources, such as starch and cellulose.

They are superior to non-biodegradable ones due to environmental concerns, such as plastic waste, global warming from CO₂ emissions during waste incineration, and the limited availability of petroleum resources.

Biodegradable polymers can be processed biologically at the end of their life cycles (composting or anaerobic digestion). The development of alternative waste management solutions encourages the integration of biodegradable polymers into the circular economy. Biodegradable materials have replaced non-biodegradable materials in several uses, such as plastic bags and even soft tissue engineering.

Polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) are the most significant biodegradable polymers. PLA is well-known for being a biodegradable and biocompatible polymer. It is synthesized from renewable materials such as potato starch, wheat, rice bran corn, and biomass.

PHAs are useful in a variety of industries, including packaging, biomedical engineering, and agriculture, because of their physical qualities, which are similar to ordinary plastics, biodegradability, and biocompatibility.

PHAs are the only polymers reported to have been entirely synthesized by microorganisms. PHA is widely regarded as safe and environmentally beneficial.

The compostability of REGEN™ is proven by meeting rigorous compostability certifications. REGEN™ products set a high standard in the bioplastics industry by ensuring compliance with certifications like FDA, ISO 17088, ASTM D6400, BPI, and TÜV Austria. Their proven biocompatibility and compostability, backed by studies and certifications, make them a safe and sustainable choice.

What Are Non-Biodegradable Polymers?

Non-biodegradable polymers are chemically inert and cannot decompose, causing them to accumulate in the environment. These polymers, including polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), harm the environment due to their ability to remain unaffected for hundreds to thousands of years.

The continuous demand has caused non-biodegradable polymeric waste to accumulate in landfills, consuming massive space and contributing to environmental hazards.

Even then, they produce fragmented micro- and nanoparticles if they break down. These micro- and nanoplastic particles exacerbate the problems by endangering human health.

There is a growing threat of global warming resulting from carbon dioxide emissions due to the incineration of non-biodegradable conventional polymers.

The chemicals used in plastic production pose further environmental challenges. The pollution crisis is accompanied by biodiversity loss. Finally, these polymers entered our food chains.

Plastic pollution has become one of the most pressing environmental issues, as the rapidly increasing production of disposable plastic products overwhelms the world’s ability to deal with them.

Biodegradable vs. Non-Biodegradable Polymers: Key Differences

Biodegradable polymers like REGEN™ PHA offer eco-friendly alternatives for applications where end-of-life decomposition is essential. Non-biodegradable polymers remain prevalent due to their cost-effectiveness and durability but pose significant environmental challenges.

| Category | Biodegradable Polymers | Non-Biodegradable Polymers |

| Definition | Polymers that can be broken down by natural processes (microorganisms, enzymes). | Polymers that resist degradation and persist in the environment. |

| Raw Materials | Typically made from renewable resources like plants or agricultural by-products. | Derived from fossil fuels such as petroleum and natural gas. |

| Decomposition Time | Degrade within months to a few years under appropriate conditions. | Can persist for hundreds of years without breaking down. |

| Environmental Impact | Minimal impact; decomposes into natural elements (CO2, water, and biomass). | Significant; contributes to pollution, harming ecosystems. |

| Common Examples | Polyhydroxyalkanoates (PHA), Polylactic Acid (PLA), Starch-based plastics. | Polyethylene (PE), Polypropylene (PP), Polystyrene (PS), PVC. |

| Recyclability | Not typically recycled; designed for composting or natural degradation. | Can be mechanically or chemically recycled but often ends up in landfills. |

| End-of-Life Options | Composting, biodegradation in soil or water environments. | Landfill disposal, recycling, or incineration. |

| Usage Areas | Single-use items (packaging, agricultural films, medical implants, 3D printing). | Durable goods (pipes, packaging, electronics, automotive parts). |

| Regulatory Support | Encouraged in industries focused on sustainability and circular economy. | Heavily scrutinized due to environmental persistence. |

| Cost | More expensive due to production methods and economies of scale. | Cheaper due to established production methods and economies of scale. |

Environmental Impact

Non-biodegradable polymers are linked to a wide range of environmental issues across their lifecycle, such as pollution, affecting the life of marine and terrestrial habitats, and involvement in greenhouse gas emissions. On the contrary, biodegradable polymers degrade in natural environments, such as soil, freshwater, and seawater, after disposal.

Many microorganisms hydrolyze biopolymers and utilize the resultant decomposed compounds as nutrients. Finally, the compounds can be converted into renewable resources, such as CO₂ and biomass.

REGEN™ biodegradable alternatives are safe for composting and improve soil health while degrading. They support the circular economy by returning to nature at the end of their lifecycle, reducing waste and reliance on fossil fuels. Moreover, REGEN™ not only reduces greenhouse gas emissions and is carbon neutral, significantly contributing to combating climate change.

Cost and Availability

The biodegradable polymers are more expensive than their petroleum-based counterparts. For instance, it costs between 1.15 and 1.21 CAD to manufacture petroleum-based plastics such as PVC, PP, and PET, whereas it costs up to 17.91 CAD per kilogram to manufacture PHA.

Higher PHA costs can be attributed to higher production costs, industrial composting requirements, reliance on feedstock availability, and the need for precise temperature control and equipment modifications. Obtaining certifications for sustainable practices incurs additional fees.

Therefore, it seems that PHA is not suitable from an economic standpoint. However, despite initial costs, the long-term environmental and health benefits make them a valuable choice. Also, certificates offer transparency and reassurance to consumers, balancing costs out. Finally, businesses prioritizing sustainability see increased brand loyalty and attract investment from environmentally conscious funds.

The cost of REGEN™ bioplastics, like most biodegradable polymers, is typically higher than conventional non-biodegradable plastics. However, their environmental benefits and alignment with growing regulatory and consumer demands for sustainability justify the initial investment.

Performance and Durability

The gap between biodegradable and non-biodegradable materials in terms of performance and durability has narrowed. The abovementioned higher cost for PHA compared to non-biodegradable polymers is offset by ideal material properties, such as elongation at break, tensile strength, and glass transition temperature.

Moreover, REGEN™ PHA is compatible with conventional manufacturing equipment, offers competitive cycle times, and has excellent mechanical and physical properties comparable to traditional PLA and non-biodegradable plastics. This makes them a viable alternative for industries requiring high-performance materials while prioritizing sustainability.

Regulatory Considerations

Environmental regulations are increasingly focusing on reducing plastic pollution and encouraging biodegradable alternatives. These regulations encourage compostable and biodegradable polymers, making REGEN™ bioplastics feasible.

Increasing regulations and bans on plastic bags and other single-use plastic items, such as drinking straws, fuel demand for biodegradable plastics. REGEN™ is committed to a circular economy, utilizing renewable resources to reduce waste effectively.

Extended producer responsibility, or EPR, is a policy approach in which producers—the businesses that supply packaging and paper—are responsible for the end-of-life management of their materials. REGEN™ aligns with EPR policies by reducing landfill contributions.

Canada’s Zero Plastic Waste Initiative aims to eliminate plastic waste by 2030 by banning single-use plastics and encouraging biodegradable alternatives. REGEN™, a leader in this field, provides eco-friendly alternatives to traditional plastics, aligning with efforts to reduce pollution and promote sustainability.

Brand Perception and Consumer Preferences

Using biodegradable polymers, such as REGEN™ PHA, improves brand perception by meeting consumer demand for sustainability and demonstrating commitment to environmental responsibility. In today’s competitive market, embracing biodegradability is environmentally friendly and a sound business strategy.

Pros and Cons of Biodegradable Polymers

The main advantage of biodegradable polymers is their environmental friendliness. They break down into harmless substances, reducing pollution and waste in landfills. They can also be derived from renewable resources, decreasing dependency on fossil fuels. Furthermore, their use in medicine and dentistry can provide benefits such as reduced inflammation and scarring compared to non-biodegradable materials.

Despite their benefits, biodegradable polymers also present several challenges. Their production can be more expensive than conventional polymers, and their properties (such as mechanical strength and heat resistance) may not be as good.

Additionally, they require specific conditions (like certain temperatures or the presence of specific microorganisms) to degrade completely, which may not always be met in natural or even managed environments like landfills.

The true advantage of biodegradable polymers compared to petroleum-based polymers lies in using renewable resources. However, this benefit comes at an environmental cost due to the impact on ecosystem quality caused by using pesticides and fertilizers and the consumption of land and water.

Pros and Cons of Non-Biodegradable Polymers

Non-biodegradable polymers are lightweight, cheap, adaptable, pliable, easily shaped, and multi-functional compared to wood, ceramics, and metals.

However, they accumulate rather than decompose, undergoing a slow degradation process and staying in bulk form for hundreds of years. The only way to permanently eliminate them is by destructive thermal treatment. Moreover, non-biodegradable polymers typically have a short service life.

At the end of their service lives, they have no economic value, as only a tiny part (<9%) of these waste plastics are recycled. Over 80% of non-biodegradable polymers become useless and enter the environment, leading to heavy economic loss.

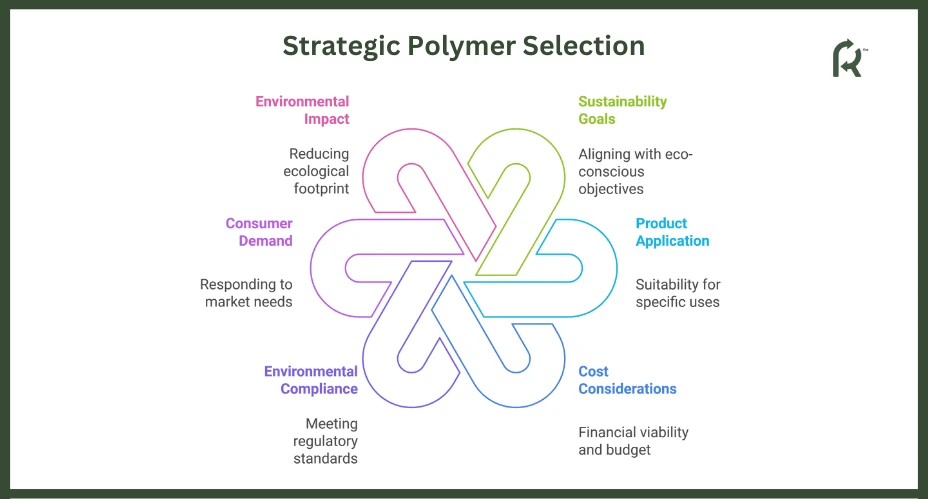

How to Choose the Right Polymer for Your Brand

Selecting the right polymer for your brand involves evaluating sustainability goals, product application, cost considerations, and compliance with environmental regulations. Biodegradable materials, such as REGEN™, meet consumer demand for eco-friendly solutions without sacrificing performance.

About 8 million tons of plastic waste directly enter the oceans each year. The leaching of hazardous compounds from plastic products (plasticizers and heavy metals) deteriorates food quality and affects consumers’ health.

Burning plastic products at dump sites is a significant concern due to releasing toxic gases into the environment. Adopting biodegradable alternatives like REGEN™ PHA can help mitigate these impacts by ensuring materials break down into non-toxic components under composting conditions. Moreover, compostable polymers require no special disposal and can be composted in soil, saving transportation costs and emissions.

Finally, businesses using compostable packaging, such as biodegradable food containers, have reported enhanced brand awareness and perception and increased consumer satisfaction and loyalty. It is worth mentioning that more and more companies, including Ikea and Nestle, have started to use bioplastics in their products.

Key Takeaways

- Biodegradable polymers are a special class of environmentally safe materials that benefit mankind and have no adverse environmental effects.

- REGEN™ bioplastics are the next generation of biodegradable materials, providing an environmentally sustainable alternative to conventional plastics.

- REGEN™ are certified compostable products made from renewable resources that help reduce reliance on fossil fuels and promote eco-friendly waste management.

Frequently Asked Questions

Do Biodegradable Polymers Cost More Than Non-Biodegradable Ones?

Biodegradable polymers cost more than non-biodegradable alternatives. However, investing in sustainable materials can lead to long-term savings. Advancing technology and widespread adoption will make biodegradable polymers increasingly affordable.

Are Non-Biodegradable Polymers Bad for Marine Life?

Marine plastic pollution is a critical global issue, with 80% of marine plastic originating from land. Coastal animals ingest plastics, causing digestive damage, mortality, or exposure to toxins. Over 1 million seabirds and 100,000 marine animals die annually due to plastic pollution.

Is It Possible to Replace All Non-Biodegradable Polymers?

Biodegradable polymers can replace fossil-based polymers due to shared characteristics. Full replacement of non-biodegradable polymers remains a long-term goal. Innovations like REGEN™ PHA significantly reduce plastic waste in key sectors.